The new Arthur L. Irving Institute for Energy and Society at Dartmouth College in Hanover, N.H., is designed for groundbreaking performance and efficiency, with expectations of achieving an energy use intensity (EUI) of approximately 18 compared to the average usage of 130 at other campus buildings. Maintaining low energy consumption, optimizing occupant comfort, minimizing the mechanical cooling needs, and expressing energy performance through design were especially important goals for the institute, which is intended to be a living laboratory for educating the next generation of energy experts.

“We wanted a building that would use between four and six times less energy than the campus average,” says Stephen Doig, research director at the institute. “It was a lofty ambition to do this in an environment that gets down to minus 25 degrees in the winter and as hot as 100 in the summer, so occupant comfort is crucial.”

The 55,000-sf, four-story building opened in March 2022. Every major building system, subsystem, and utility is metered to obtain real-time data, but the information and the actual EUI—measured in thousand BTUs (kBTU) per square foot per year—is not yet available.

Design Highlights

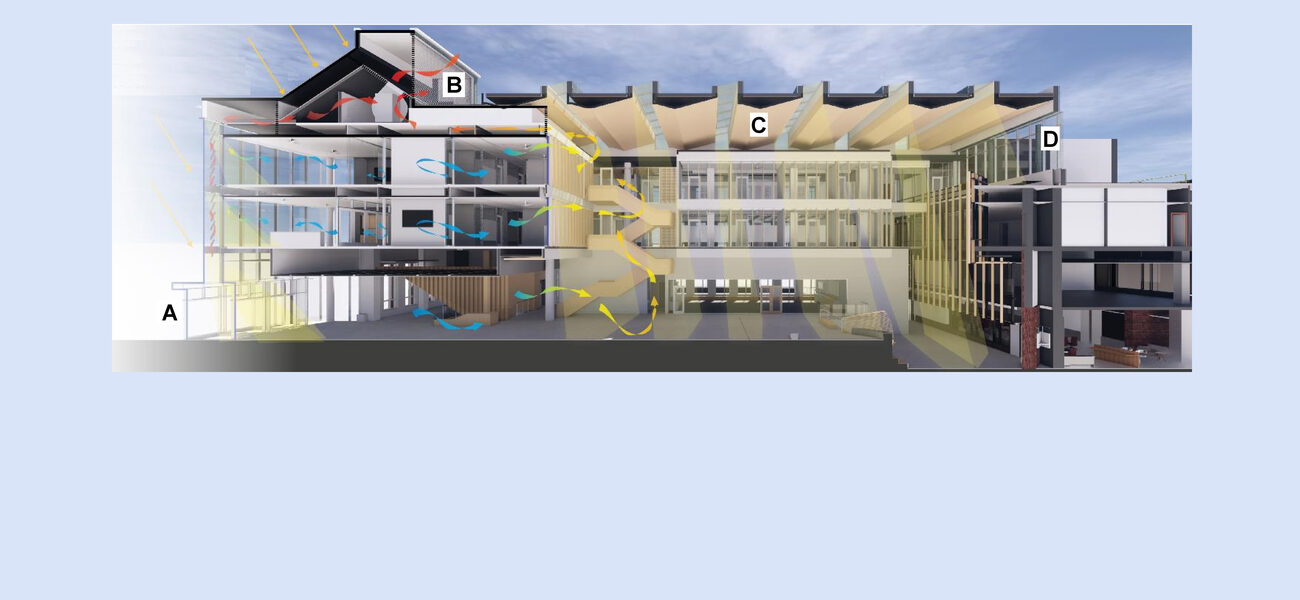

Strategies used to accomplish their goals included reducing the heating and cooling loads, maximizing the use of passive systems, finding renewable energy sources, and streamlining the building operations by using a radiant heating and cooling system; taking advantage of natural daylight; employing natural ventilation; and creating a robust thermal envelope by using a double-skin façade, high-performance windows, and building automation systems.

Photovoltaic panels, designed to generate approximately 90 kilowatts of electricity, will produce enough energy to provide a large portion of the building’s power for the next 25 years. They will be installed on the roof in the next phase of the project.

“The college has been pushing for sustainability, smart design, and integrated processes in an effort to reduce emissions since 2015, and they have hit those targets,” says Eric Fontaine, an associate at van Zelm Engineers.

Heating and Cooling

“All of our systems were set up on day one for low-temperature hot water throughout the building for heating needs, and high-temperature chilled water for all of the cooling needs,” says Doig. “In keeping with Dartmouth’s long-term carbon neutrality plans, the mechanical space is designed to accommodate heat pump chillers at some point in the future.”

Because the Irving building is connected to the energy-intensive Murdough Center, which had an EUI of about 228, Murdough’s HVAC systems were upgraded, dropping its EUI to 93 and eliminating the need to install a substation for the Irving project. The Murdough MEP infrastructure was converted from variable air volume to a dedicated outdoor air handling unit for both buildings. Existing reheat piping in Murdough was repurposed for the chilled water distribution system in Irving, and Murdough’s 97,000-CFM (cubic feet per minute) unit was replaced with a 30,000-CFM unit that services both buildings. Utilizing the existing MEP at Murdough and repurposing other systems, rather than installing new ones for Irving, resulted in annual energy savings of about $300,000.

The hydronic heating and cooling system that circulates water is a major component of the MEP system at Irving because it requires less energy than forcing air through ducts. A radiant heating and cooling system under the atrium floor pumps water through tubes, offering an efficient method of regulating room temperature by circulating warm water to heat spaces and cold water to cool them.

Perforated metal radiant ceiling panels in workspaces and radiant sails in the labs on the second and third floors provide a uniform temperature year-round. Heat recovery technology and a dedicated outside air system are used to recover energy that would typically be lost if the inside air were directly vented outside. Instead, stale, warm air passes through a heat exchanger that warms up the colder fresh air from the outside in the winter. In the summer, the indoor air passes through an exchanger to make the incoming air cooler and dryer.

Natural Ventilation

“The natural ventilation is set up and controlled to only operate when outdoor air conditions—dry bulb temperature, dew point temperature, and wind speed—are favorable,” says Arjun Mande, a principal at Goody Clancy.

Designed to handle the New England humidity, the ventilation system leverages the natural air flow created by the building’s design to minimize the need for mechanical cooling, while still providing thermal comfort for occupants. A primary feature of the system is the building’s double-skin glass façade, which acts as a solar chimney to draw heated air up and out of the building’s rooftop exhausts. The outside curtainwall, air cavity, and inner double-glazed curtainwall create an efficient thermal barrier that minimizes heat loss in the winter and heat gain in the summer.

High-performance triple-glazed windows save energy by minimizing heat transmission and air leakage. All windows in the building are automated, opening when the outdoor environmental conditions are advantageous to supply fresh air to the indoor spaces. Under the automated system, all windows in the building will open simultaneously when the building goes into natural ventilation mode. Each space also has manual override switches that enable users to opt out of the current automated setting for a limited period of time.

All punched openings in the building have awning-like operable windows, which hinge at the top and have a single actuator at the bottom. Automated exterior venetian blinds on the first-floor windows block solar heat in the summer and enable the heat to enter the building in the winter.

Energy-efficient ceiling fans are used to improve airflow and enhance occupant comfort without the need for air conditioning in workspaces on the first, second, and third floors. High-speed exhaust fans are used when necessary to draw air up through the building, and push it outside through louvers at the top of a thermal vent on the roof.

“The design of the natural ventilation system specifically influenced everything from massing to the exterior envelope articulation to the atrium wall articulation, and even the office layout,” says Elaine Hoffman, an associate at Goody Clancy.

Natural Lighting

The atrium provides an open design that allows plenty of natural light to flow into the building from the glass entryway, the clerestory windows near the building’s ceiling, and the six linear skylights. More than 90 percent of the institute’s workspaces receive natural light from these design features, offering a comfortable work environment and views to the outside.

Mande notes that extensive analysis and conversations with all stakeholders ensured that the interior would be bright, even on cloudy days, thereby enhancing comfort and reducing reliance on electricity during daylight hours.

Integrative Design Process

The success of the project is partially attributed to the use of an integrative design process (IDP), which engages all stakeholders throughout the entire design and construction phases to make the best decisions for creating a high-performance building. IDP incorporates the use of goal-setting sessions, workshops, charrettes, analysis, and research.

“The IDP impacts both the building design and the design team itself,” says Hoffman. “Many team members were involved in significant decisions throughout all the design phases. This collaborative approach allowed the performance goals to gain momentum as the design was refined from the concept phase through the construction documents.”

This type of design approach requires attention, engaged listening, and active participation. Members of the design team depend on each other’s expertise, resulting in a process that is less hierarchical, more robust, and more successful than conventional design decision-making. Establishing shared goals at the beginning of a project is essential with the understanding that decisions about the design or construction may change during the process to better suit the users, align with budgetary objectives, or enhance building performance.

Mande stresses the importance of setting goals and gathering information from stakeholders as early as possible at the beginning of a project. The stakeholders included not only the usual design team, construction team, and construction manager, but also a building consultant, leaders from the institute, and individuals who now occupy the building. The stakeholders who designed the building systems relied on each other and the building users to continually refine each aspect of the building until the highest level of efficiency, sustainability, performance, and flexibility was achieved.

For example, since plug loads in labs can consume a high level of energy, the users were asked about the energy requirements necessary to perform their work, and their answers facilitated changes that significantly decreased the EUI.

“If the lighting was coming in a little more expensive, then the controls had to be adjusted or the type of fixture had to be changed, and if that happened, the architect and institute leaders came into the picture,” says Mande. “That is where true integration happens.”

The design team created a brochure to provide an overview of the building features, and green building educational signage is located on the first floor to help occupants and visitors understand the sustainable elements and how they work.

Mockups

Mockups were built to test the performance of various building systems as they were being designed, avoiding the need for changes and improvements during construction.

“Two performance mockups were done, one for the curtainwall and the other for the windows,” says Doig. “All window installation details were built and tested for air infiltration and exfiltration. This confirmed the robustness of the detailing, and provided a baseline for reference.”

In addition, the mockups worked through flashing and brick detailing around the windows. Multiple passes were needed before the work was allowed to proceed in the building.

Lessons Learned

Completing a high-performance building requires the ability to convert obstacles into opportunities. Convincing team members to use a less familiar air flow system presented a challenge that morphed into an opportunity to expand the functionality of the natural ventilation system to enhance occupants’ comfort.

“Giving each other the time and space to challenge each other to continually refine our concepts and advance solutions all the way from the big ideas at the beginning to the smaller details at the end was a major contributor to achieving high performance,” says Hoffman.

By Tracy Carbasho

| Organization | Project Role |

|---|---|

|

Goody Clancy

|

Architect

|

|

Turner Construction

|

Construction Manager

|

|

Van Zelm Haywood & Shadford

|

MEP Engineer

|

|

Transsolar

|

High-Performance Consultant

|