New rules on mass timber construction in the 2021 International Building Code (IBC) significantly expand the opportunities to use engineered wood as the primary structural material in laboratory buildings. The updated version of the code establishes three new types of construction that now permit “mass timber buildings of taller heights, more stories above grade, and greater allowable areas compared to existing provisions for heavy timber buildings,” according to a summary from the International Code Council.

The timing of these new regulations is especially fortuitous in light of the Paris Accord goal of reducing greenhouse gas emissions to net zero by 2050. With the global building stock expected to double in area by 2060, mass timber presents a realistic and meaningful alternative to steel and concrete and the notoriously high levels of CO2 emissions their production entails.

“We are currently experiencing an explosive boom in real estate development all across the world,” says Jacob Werner, associate principal at Ellenzweig, formerly of Perkins&Will. Werner pointed in particular to the enthusiasm for new laboratory buildings among U.S. developers. “As architects, engineers, and owners, we need to change the paradigm of how we build, and look at different materials that are better for the environment and for the occupants inside.”

The sustainability of mass timber is a major appeal, but several other considerations enter into decisions on its use as a structural material in a lab building—specifically, fire protection, chemical control areas, and vibration levels, according to extensive research conducted at Perkins&Will’s Material Performance and Building Technology Research Lab. It may not be suitable in demanding specialty labs with high chemical loads, higher biosafety levels, or strict cleanroom requirements, Werner points out, but in the conventional open lab with a variety of different hazards, none at extreme levels, an engineered wood structure is definitely a feasible, lower-carbon option.

It may take awhile for jurisdictions to actually adopt the new addition to the base code, but “if mass timber has made it into the IBC, it’s here to stay as an established building construction type,” notes Jeremy Lebowitz, market leader, Northeast, Jensen Hughes. “It is a prescriptive solution. You don’t have to go through all the procedural hoops to get it approved on a case-by-case basis as a performance-based design.”

Introducing Types IV-A, B, and C

Designated Types IV-A, IV-B, and IV-C, the IBC’s three new mass timber categories are distinguished primarily by the nature of their noncombustible protection. In Types IV-A and IV-B, the wooden structure is underneath the skin of a noncombustible material, either fully protected (A), or semi-protected (B). Type IV-C is exposed wood, which, if involved in a fire, does not sustain combustion due to charring and lack of oxygen after the compartment fire burns out, explains Lebowitz.

The new types are an outgrowth of the previous Heavy Timber classification (now known as Type IV-HT), but with increased fire-resistance ratings and required noncombustible protection, according to the Wood Products Council.

Addressing other potential fire vulnerabilities, the latest code changes include the mandate for a daily fire safety inspection during construction and some kind of protection for concealed spaces in the completed building, typically gypsum board or sprinklers.

“Assume the lab will have sprinklers,” says Lebowitz. “In any case, labs with wet chemicals will need a chemical resistant floor regardless of the construction materials.”

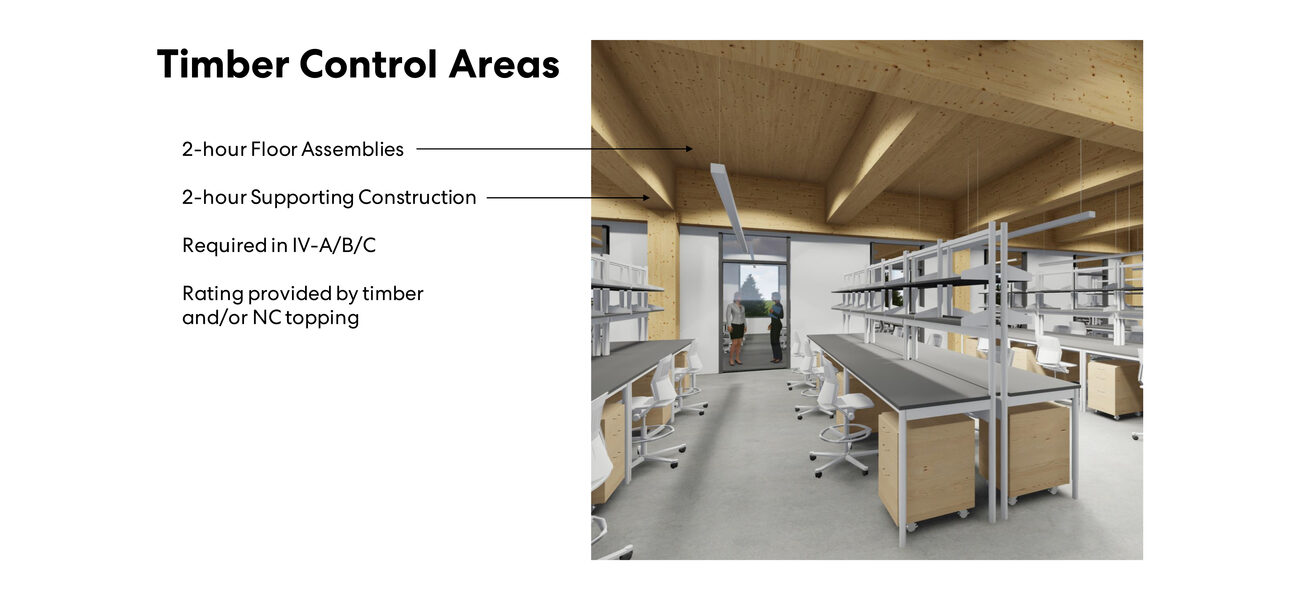

Delving more deeply into questions about the compatibility between chemical use and engineered wood, Lebowitz points out that recent studies confirm that mass timber floor assemblies and supporting construction are sufficient to provide the two-hour fire resistance required for chemical control areas.

“This is new,” he says. “It means designers can ‘plug and play’ the structural system anywhere a two-hour assembly is needed, for example, in a chemical control area. What remains constant is that other measures besides structural fire resistance are factored into the overall protection scheme for laboratories, including quantity limitations on hazardous materials and requirements for more robust fire protection systems such as automatic sprinklers.”

As for the impact of chemicals on fire intensity, Lebowitz observes that the issue is covered by a different section in the codes. “In higher education and most labs doing typical bio/chem/wet-bench type work, the presence of chemicals is being managed in a way that is commensurate with a Use Group B (business) occupancy,” he says.

Fire Performance

When designing a mass timber building, structural engineers must pay scrupulous attention to the load-carrying capacity of the structural members.

“When fire attacks wood, it burns, creating a char layer around the perimeter of the face exposed to the fire,” explains Michael Gryniuk, a principal and structural engineer at LeMessurier.

While the char layer insulates the element from heat, for load capacity calculations it is assumed to be a zero-strength layer. Instead, load capacity is based on the residual zone within the timber element. The size of the residual zone is determined by an effective char rate and depth under various fire endurance requirements, using tabulated nominal char rates based on extensive testing.

“We do not consider the original section size when designing mass timber elements that could be exposed to fire,” says Gryniuk. To illustrate, he cites one example where for a one-hour rating, the outside of the element was reduced by 1.75 inches all around the exposed faces. “A two-hour rating is nearly twice that, with 3 inches off all around that member when considering the design capacity.”

For cross-laminated timber (CLT) panels—popular engineered wood elements that can replace typical concrete-on-metal deck systems—it is not surprising to learn that thicker sections provide the largest residual capacity. In a two-hour fire rating scheme, the reduction in load-carrying capacity could range from 0 to 25 percent for a seven-ply panel, while a five-ply system, depending on the thickness of the plies, might have up to a 70 percent reduction. Gryniuk notes that three-ply systems are unlikely to be used for a two-hour rating scheme because “there is basically no capacity remaining in that scenario.”

Good Vibrations

Designing mass timber floors for modest to stringent vibration limits is relatively new for the A&E community. Vibration analysis is complex even with traditional materials, and computer modeling is necessary to account for the impact of adjacent bays, contiguous floors, and other influencing factors. Gryniuk and his team ran iterative computer analyses adjusting the stiffness and mass of girders and beams to determine how to achieve laboratory-grade vibration performance in an engineered wood structure.

The peak velocity upper bound target was set at 2,000 micro-inches per second (μin/s), classified as VC-A, the level appropriate for sensitive lab equipment like mass spectrometers and powerful bench microscopes. The study results were promising.

In general, the two most common ways to mitigate floor vibrations are to add mass, using, for example, concrete topping slabs; or to add stiffness by increasing member depth, shortening the beam spans, or taking advantage of composition action between the beams and the decking elements. Other mitigation measures include adding damping to the system or employing equipment vibration isolation tables.

To attain the desired velocity target of 2,000 μin/s, Gryniuk used what he calls a heavy girder option in the computer model.

“This entails shallowing up the beam elements and then deepening the girder, trying to have it do more of the ‘work.’ Coupling that with a modest increase to the CLT panel thickness, we were able to reduce the beam depth by about 9 inches.”

That reduction allowed for a more functional layout of the MEP and lighting systems. “The deeper members are one of the more challenging obstacles to overcome with stringent vibration limits in a mass timber building,” he relates.

Wood Is Our Friend

There are many reasons to switch a lab project to mass timber, ranging from the aesthetics and wellness benefits to the flexibility to repurpose occupancy for office or light assembly in the future. But the most compelling reason is the carbon, says Werner. A building’s carbon footprint has two components: operational and embodied carbon, he explains. Operational refers to a building’s energy consumption, including for repairs and replacements; and its impact on its environment, reduced through tools like passive design, renewables, efficient systems, load reduction, and—especially significant in lab buildings—lower air change rates.

The embodied component encompasses all the other elements of the building lifecycle: extraction, transport, manufacturing, construction, demolition, and disposal. All these activities have an environmental impact that can be accounted for in carbon terms.

Over the past few decades, the carbon reduction effort has tilted overwhelmingly toward operational carbon. A new focus on embodied carbon would better balance the equation.

Key strategies to decrease embodied carbon are materials selection and offsetting, carbon avoidance, and carbon sequestering. Mass timber today not only helps to reduce the embodied carbon on the avoidance side, it also has a really important sequestering effect. Growing trees pull carbon out of the atmosphere and store it in the wood, which, when incorporated into a building, sequesters the embedded carbon for 100 to 150 years.

“Reimagining the use of wood, both in the structure and things like laboratory casework, could generate as much as a three-quarters reduction of the embodied carbon in a building,” says Werner.

“Wood is our friend,” concludes Gryniuk.

By Nicole Zaro Stahl

[The content of this article is based on research performed by Perkins&Will’s Material Performance and Building Technology Research Labs in collaboration with Jensen Hughes and LeMessurier.]