Ohio State University is creating three-dimensional models of its existing buildings as part of a comprehensive plan to address space management needs and to make informed decisions regarding renovation, construction, and maintenance projects.

Facilities management leaders at OSU first began discussing the use of 3-D Building Information Modeling (BIM) in 2008, prompted by the realization that traditional two-dimensional AutoCAD architectural drawings provide a limited view of building floor plans and, therefore, cannot offer an accurate representation of available space and associated data.

“Most of the people we work with are customers. When they look at a two-dimensional floor plan, it is hard for them to visualize the space,” says Joe Porostosky, senior manager of facilities information and technology services at OSU. “As facility planners, we live in a 3-D world, but most of our customers do not. We recognize that our customers, those who often make decisions about the plans we give them, would have a much better understanding of what is going on if they had a 3-D model of the space.”

Converting from an AutoCAD system of space management to BIM got under way in 2010 when senior leaders approved the development of new models for the 53 buildings that comprise the university’s Wexner Medical Center. The buildings encompass a total of just over 6 million sf.

Undertaking such a large endeavor required a steadfast commitment from management, an understanding of what OSU can achieve by using BIM, and a methodical approach to implementation. Having a solid plan with defined short- and long-term objectives was essential in convincing OSU’s leadership to support the transformation to a BIM culture.

Making BIM Happen

Porostosky’s team developed a detailed implementation plan to outline the timeline and resource requirements for a complete conversion. The comprehensive information provided in the implementation plan was instrumental in helping the team obtain funding from the university to proceed with the project. The plan cites OSU’s anticipated immediate benefits, including:

- High-quality 3-D visualizations;

- Energy analysis and modeling;

- Improved planning in the areas of space, operations, security, and others;

- Improved drawing accuracy via field verification and further use of as-built documentation;

- Improved communication with leadership and customers regarding space usage and layout;

- Time savings in updating to BIM following construction or renovation projects compared to AutoCAD;

- Utilization of industry drawing standards.

Benefits OSU expects to realize in the future include the detailed location of and information about various types of equipment; 3-D campus maps; improved wayfinding services; and better support for safety, security, disaster planning, and other expanded services. All of the objectives are aimed at the overriding goal of improving the decision-making process, which will ultimately save the university time and money.

“We started the program because we believe it will not only enhance space planning, but also improve the quality and speed of decision making in the areas of facility use, renovation planning, maintenance, wayfinding, and energy consumption,” says Porostosky.

Multi-Phased Approach

Porostosky cites partnering with a BIM-knowledgeable architectural firm as a critical first step in OSU’s project. The university collaborated with DesignGroup, based in Columbus, to initiate the conversion. The planning stage, also known as Phase 0, began in February 2011 with the selection of university staff members to serve in various roles, such as the BIM coordinator and project champion. Five architecture and engineering students were chosen to serve as assistants.

Phase 0: Standards and Process Development

The team kicked off Phase 0 by reviewing existing architectural drawings of the medical center buildings to determine whether sufficient space data was available, and whether facility components, such as the location and dimensions of doors, were correctly represented. A thorough review of the AutoCAD floor plans revealed that they lacked information pertaining to floors; ceilings; roofs; exteriors; and the height of windows, doors, and walls—all information they need to build the BIM models. A field verification was conducted to determine the accuracy of existing floor plans, and photos were taken of building exteriors and unique features. OSU and DesignGroup used the information to develop standards to which the BIM models would adhere.

“We want each of the models to be within 1 percent accuracy or 1 percent deviation from the actual conditions,” says Porostosky. “The initial field verification determined that only seven buildings failed to meet this standard in the AutoCAD drawings and would need additional data added in the BIM model. People might think 1 percent is an unusually high standard, but most of our buildings were already within 1 percent accuracy, so we knew it was possible.”

Phase 0, which took about four months, also included creating templates to convert the AutoCAD drawings to BIM models using Revit® software, and developing a detailed process map and workflow integration chart. Porostosky said the work done in Phase 0 is critical to the overall success of a project because it addresses many decisions that would be difficult to change later in the process. Estimates show completing Phase 0 took five staff members approximately 1,080 hours, meaning preparation time for the project was 0.011 minutes per sf.

Phase 1: Big Bang Implementation

A three-day customized training session was conducted to teach the five students how to use the Revit® software to model the existing facilities. The training also presented an opportunity to execute the newly defined process map and workflow integrations to translate the information from 2-D to 3-D. Members of OSU’s engineering and operations staff, interior designers, space planners, and construction managers also were trained in the process.

“No matter where you put BIM in your organization, it represents a cultural change that requires the proper training to ensure the different stakeholders understand how to use the tool,” says Porostosky. “You can teach technology, but changing the culture is more critical. As more people see the value in the information-rich BIM models, more people will want to start using them.”

After the training session, students were asked to develop their first BIM model. A careful audit was conducted to document the adherence of their first model to the BIM standard created by the OSU team. The effort provided a roadmap to audit and modify additional models as they were created.

Developing models of the 53 buildings in the medical center complex took about a year to complete at a pace of 0.066 minutes per sf. The cost for the students’ work was approximately $40,000 with an additional $40,000 for the consultant. The total amount paid to staff members who served on the team was about $72,000, but Porostosky stresses this is not an additional expense because they would have been paid the money anyway for doing their regular work.

Outcomes

The transition to BIM is producing beneficial outcomes for OSU, and the medical center in particular, helping staff, faculty, students, patients, and visitors make better decisions more quickly. One of the most noteworthy benefits is the ability to visualize different renovation options for a given space. Previously, customers were given several 2-D plans of a space and asked to decide which one they liked best. They would frequently be unhappy once they saw the completed space, and the university would incur expenses making changes.

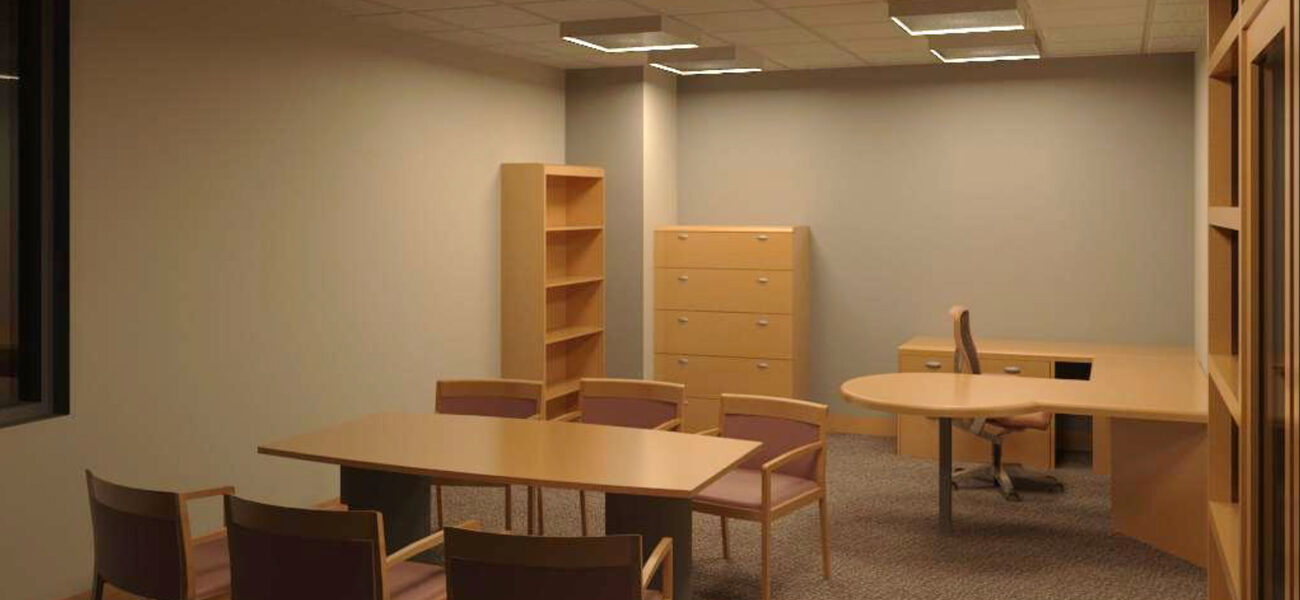

“Recently, we were able to send an incoming senior leader several 3-D renderings of her office space with the furniture we intended to purchase,” says Porostosky. “She indicated how much easier it was for her to understand how her space could be used. It’s all about cost avoidance for us, rather than cost savings.”

BIM is also making a difference in helping OSU leaders make funding decisions. In the summer of 2011, medical center leaders were trying to determine if they should invest in new finishes for the emergency department. Using BIM, the proposed finishes were added to the model, allowing decision makers to accurately visualize what the renovated space would look like.

Vivid visualizations are also providing prospective donors with the ability to see how a space might look with their name on it. OSU leaders are using BIM to help select the best signage to complement a building’s architecture while prominently displaying a donor’s name.

Future Opportunities

In addition to using BIM to facilitate better decision making, OSU intends to utilize the tool to improve patient and visitor wayfinding; to recruit staff and students; to improve asset management and disaster planning; and to review and possibly reduce energy consumption. It is too early to predict the outcome of those plans, says Porostosky.

Studies are under way to see how BIM can improve wayfinding. This could be especially valuable to the university because approximately 1.4 million patients and visitors pass through the medical center each year, with about 40 percent expressing difficulty in finding their way to a certain location.

OSU leaders are looking forward to using BIM throughout the rest of the campus, with its approximately 30 million sf in 800 additional buildings. Developing models of so many buildings will take several years to complete, says Porostosky, but the benefits will be worth the wait.

“We’re in the process of developing BIM implementation standards for new buildings, which we hope to have completed around June 2014,” he says. “This will help us when we design and construct new buildings on campus.”

Lessons Learned

It is important to recognize that converting to BIM is a cultural shift, says Porostosky.

“We could have transitioned all of our buildings to BIM, and no one would have used the models,” he says. “They would just continue to use the AutoCAD drawings that we export out of BIM. Training staff members, letting them see the value of BIM, and sitting down with them when they do their first renovation project, are critical to increase adoption.”

Partnering with an architectural firm that is knowledgeable about BIM is also essential to achieving success. Finally, completing as much preparation as possible in Phase 0 plays a critical role in the successful implementation of any BIM transformation.

By Tracy Carbasho

This report is based on a presentation given by Porostosky at Tradeline’s 2012 Space Strategies conference.