Today’s high-performance laboratories can be categorized into three different “platforms,” or core facilities, each with a unique set of metrics and key features that set them apart in terms of productivity, ability to support emerging programs, and economy of operation (both capital and energy). Understanding the distinguishing features can increase productivity and operator efficiency, and ensure the proper investments for future flexibility and adaptability.

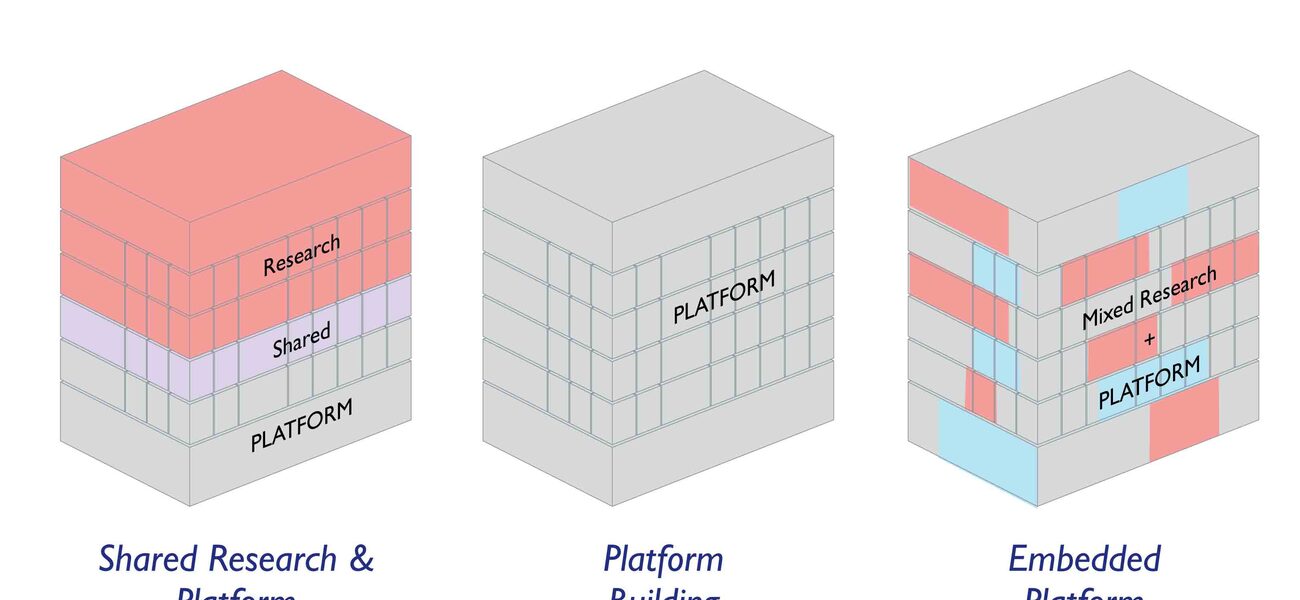

High-performance laboratories include facilities like cryogenic labs, condensed matter labs, high bay labs, and cleanrooms. The three basic platform types are:

- Shared research platform

- Platform building

- Embedded platform

“We use the term ‘platform’ because it implies something different than just the shared physical space located in these facilities,” says Samir Srouji, principal with Wilson Architects. “It implies growth, something that you can build upon.”

“These are not a survey across all possible typologies,” he says. “But there are specific differences in how each type fits into the bigger picture for their institutions in terms of research, why the institutions picked those facilities, and how they engaged research and the core facilities together.”

Cleanrooms and electron microscopes may also facilitate the science in core facilities so they can be viewed as an ancillary type, he says. These spaces require high-performance vibration and noise isolation, electromagnetic interference (EMI) mitigation, temperature stability, and humidity control because of the sensitive electronics involved.

The relationship between different criteria is also important, says Joseph Gibbons, an associate with Wilson Architects. “For example, clean class, temperature control, and humidity control are done with a lot of air that usually shakes the floor. To get high performance in clean class simultaneously with high performance in vibration, it is important to know the parameters of each and how they work together.”

“Your own building causes most of the noise problems you must invest in mitigating. The challenge is striking the right balance so that the right instruments are performing the right way in the space,” adds Srouji.

Designing the high-level building needed for core labs by duplicating areas or making it flexible enough to put equipment anywhere is expensive and counteracts the building’s purpose.

“Institutions think of core facilities as a place for people to meet and exchange ideas and share. It is not just sharing because of efficiency; it is because an institution is a home for collaboration and exchange of ideas,” says Srouji.

Shared Research Platform

Shared research platform is the most common type of core laboratory building. The platform is on the bottom level/s, topped by shared spaces, then research spaces on the upper floors. Included is research space for recruitment, and shared platforms like cleanroom, imaging suite, and high bay/cryogenics labs, which are meant to serve the inhabitants of the building and the larger community. Unique drivers in shared research and platform buildings include electrical distribution/shielding against EMI, conflicts between magnets and electron microscopy, particle counters, and helium recovery.

Two-thirds of the Laboratory for Integrated Science and Engineering (LISE) at Harvard University sits underground, and the other third is a tower primarily housing assignable research laboratories. Because the building is in densely developed Cambridge, they had to dig about 40 feet to get the proper vibration control.

The basement floor of LISE houses an imaging suite and is composed of 20-ton inertia blocks built without isolation (a way to pump in air or passively utilize a spring to raise the concrete blocks a quarter inch for even higher vibration prevention). The building was designed for the NIST vibration standard, so isolation is needed only if a more stringent VC-G (velocity of slab movement criteria) standard is required; since the building was completed in 2008, only a few rooms needed isolation, says Srouji.

Above the imaging floor is the cleanroom, which is a bay and chaise design that slopes upward. “It is about 30 feet towards the highest point. There is a loading dock and a major switchgear room on one side, and duct distribution from a penthouse on top all the way down,” he says.

The loading dock level is also the fan deck level, where the air-handling units feed into the cleanroom. Hazardous materials are delivered here and distributed via a hazardous production materials (HPM) corridor. Truck access is next to a cleanroom adjacent to the HPM corridor, and the space has “blow out” panels, so the force of an explosion would release outward instead of inward.

The design team found the quietest spot in the building to serve as the baseline for nanotechnology equipment; they dub this the “sweet spot,” says Srouji.

“If you don’t put the most expensive, sensitive equipment in that location, you have to spend money later to mitigate.”

The perimeter of the cleanroom and the imaging suite were not initially planned, but the design allowed for a suspended distribution corridor to be added. The space was designed to be high bay for any future user, and the basement was 15 feet floor to floor for another dedicated research space. Anticipating the requirements of physics experiments, they also designed a “pit” floor opening in the basement slab, which is a hole with stainless steel rebar around it. The forethought paid off when a future researcher needed 45 feet of height.

The LISE building is 143,000 gsf with a 9,000 sf cleanroom, 6,400 sf imaging suite, 6,350 sf materials synthesis lab/suite, 2,400 sf high bay lab, and 2,400 sf low vibration lab. The design team tried to achieve a 1 milligauss baseline for the EMI, and in the imaging suites alone it is 0.1 milligauss.

“Electrical distribution required shielding to get to our criteria. At one point, the scientists realized they had huge, powerful magnets right next to the electron microscope. It was discovered a bit later in the schedule than it should have been. The costly but effective solution was self-cancelling magnets for those cryo experiments, as opposed to shielding everything. You always want to solve the problem at the source when you can.”

One lesson learned in designing LISE was that electrical loads should be determined upfront, says Srouji. Based on the researchers’ requests, they designed for 108 watts per sf tool load in the cleanroom, but it is operating at only 8 watts.

The LISE cleanroom consumed more energy than Harvard wanted. The issue was resolved by connecting particle counters to the HVAC system allowing the mechanical systems to dial back when the room is functioning to clean standards and ramp up if, say, someone leaves a door open.

Platform Building

The platform building is also a shared facility. Features include:

- Two-level cleanrooms

- Characterization in deep basement

- Rigid steel frame

- Maker-space

- 3-D immersive visualization

Unique drivers include active EMI cancellation, VAV exhaust, ECMs for energy use reduction, and clean elevator and stairway.

MIT’s new nanotechnology facility (MIT.nano), for example, offers connectivity and collocation for all users, says Srouji. The whole facility is designed as a campus resource; the building contains one entry point for its two cleanroom levels, and the 3-D immersive visualization area is used by the whole campus.

The planning team took a layered approach to mitigate the transfer of noise to the imaging suite by creating a room within a room and several wall and floor layers, a concept resembling a Russian nesting doll.

The MIT nanotechnology building is 214,000 gsf, with 38,000 sf of cleanroom, 11,000 sf of imaging, 2,500 sf of non-clean lab space, 8,000 sf of maker space, and 4,000 sf of sub-fab below the cleanroom floor.

The design team needed to achieve 0.1 to 0.3 milligauss EMI criteria in the electron microscope and electron-beam areas, says Srouji. Clean class ranges from 100 to 10,000.

Using the lessons learned on the LISE building, the MIT design targeted 30 watts per sf energy consumption. “It still may be high, but MIT chose a more robust capability,” notes Srouji. “No one wants to go into a building like this and run out of power two years later.”

Embedded Platform

The embedded platform type contains platform space in different parts of the building, along with mixed research spaces. This type requires features like clean building with air acuity, high bay and pseudo-high bay areas, and centralized platforms, as well as class 100 and 1,000 cleanrooms, helium recovery system, VC-G vibration criteria, and active and passive noise cancellations.

Unique drivers in embedded platform projects include:

- Creation of high bay in existing building

- Improved slab performance in renovation

- Designed for flexibility and adaptability

- Greater than 95 percent efficient helium recovery system

- Creating the “sweet spot”

- Creating clean zones

The University of Pittsburgh’s Mid Campus Complex is an interconnected five-building complex, with core facilities evenly spread throughout the research spaces. The renovation of an embedded platform building, the Nuclear Physics Lab (NPL), for the Pittsburgh Quantum Institute (PQI) presented a challenge because the entire NPL building was “charged,” meaning it was magnetized from a cyclotron that operated there for about 30 years.

“There was no one sweet spot,” says Gibbons. “In every room, we had to provide active and passive cancellation, which became really tricky. But the vibration performance was fantastic, because the building is built into the side of a solid shale mountain and has 5-foot-thick concrete slabs.”

Each building had spots where the design team could take advantage of it being embedded in rock and add shielding to create sweet spots.

Existing high bay space allowed the design team to provide two layered imaging suites, like the ones they designed at MIT, and isolate them. They created pseudo-high bay space in a refrigerator area—the only area high bay space is usually needed—by cutting through the slab and creating a mezzanine space above.

“We often give whole rooms high bay space, but PQI had a specific piece of equipment that needed it,” says Gibbons.

The Nuclear Physics Lab building is a series of clean-class rooms with core spaces and private labs that serve as the fabrication labs for each PI. “We provided at least two of each type of this core. They didn’t necessarily have all the desired equipment, but allowed for expansion and growth of the PQI, and promoted collaboration and a move into certain types of equipment rather than everybody going off on their own,” says Gibbons.

The five buildings total 160,500 sf of renovated space, 7,000 of which is class 100 to 1,000 space. The rest are class 10,000 spaces, or basically dust-free. Two high bay, two pseudo-high bay, and two trenched labs offer 15 low-vibration spaces total. The baseline for high-performance lab in this campus was VC-E, but they often achieve VC-G simply because of the shale, adds Gibbons.

“Where high vibration performance was required (in the Pittsburgh project), we took advantage of the concrete construction we were given and cut openings. We cut trenches, we cut pseudo-high bay space, and we cut pits. The equipment didn’t always require this, but that allowed us to restructure and reframe to redirect loads,” explains Gibbons.

Lessons Learned

When designing core facility platforms, design for strict metrics, because you will eventually have equipment requiring them, advise Srouji and Gibbons. For example, anticipate taller, more powerful and more sensitive instruments and protect the sweet spot to accommodate this.

Platforms are the byproduct of the research trends, the nanoscale, and the convergence of the different sciences, so pay attention to those trends, as well as the unique drivers. “Approximately 80 percent of our current projects contain some form of a platform, whether cleanroom, imaging, or genomics, these spaces drive the design.”

By Taitia Shelow