SUNY Buffalo State has completed the second phase of a three-phase project that will transform its science education facilities by consolidating multiple science departments into a single facility, establishing a hub for the STEM curriculum. Originally built in 1962, the 171,000-sf Science Building No. 15 undertook a $107 million expansion project to create a science complex that is one of the few interdisciplinary facilities in the SUNY system. Housing programs in biology, chemistry, physics, earth science, mathematics, and science education, as well as a new planetarium and an interdisciplinary research institute focusing on the Great Lakes, the complex is designed for the collaborative efforts at the heart of 21st-century science.

Phase 1 saw construction of a 96,000-sf addition along the building’s west side to house new teaching and research labs, faculty offices, and instrumentation rooms. The four-story addition, completed in 2014, is connected to the existing structure with a three-story atrium. Phase 2 includes demolishing the building’s south wing, constructing a 61,000-sf addition and fully renovating its 63,000-sf north wing. This phase includes departmental offices, multi-use classrooms, physics research and instructional labs, a new science and mathematics teaching center, and vivarium.

Phase 3 is scheduled to be completed in 2018. It will include the “indoor campus link” that will connect outlying residence halls to the center of campus. Additionally, the research labs, classrooms, lecture hall, and planetarium will be completed at the end of this phase. Remaining site work will also be completed, which will include a greenhouse with rainwater collection, a geological garden with integrated teaching space, and a “rain garden” near the main entry, which will be used as a hydrologic-cycle learning tool.

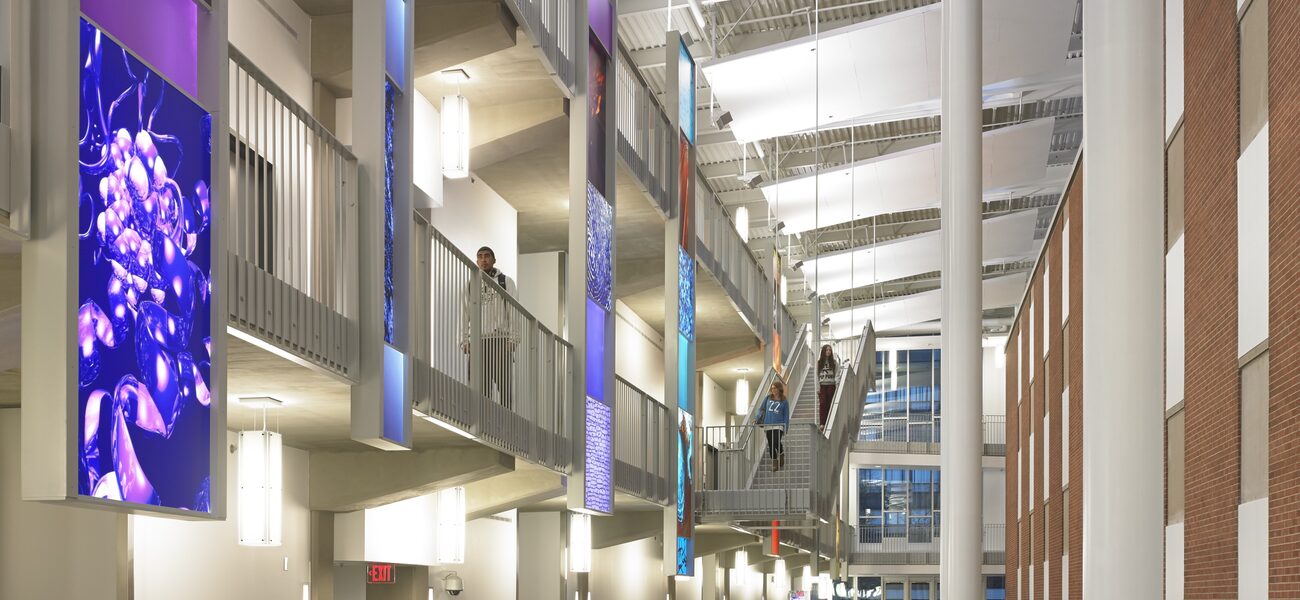

An open, contiguous, modular floorplate accommodates all required lab functions. Bridging the new construction and existing Science Building, the atrium provides a venue to put science on display, and accommodates many social and group functions, including an annual science fair. Three above-ground floors of the addition accommodate wet labs, research, and lecture labs, including a small vivarium in the lower level.

Designed for interdisciplinary collaboration, the project fulfills a number of program objectives, including improved student access to faculty and department chairs, high-visibility spaces to promote the sciences among the student body, flexible and adaptable spaces to better attract and accommodate new faculty, and informal student interaction spaces to encourage learning outside of classroom and laboratory settings.

Hydronic coils in the laboratory exhaust air stream recover heating energy and transfer it to preconditioning coils in laboratory air-handling units. Central station air-handling units are equipped with fan arrays that use less energy than larger belt-driven fan systems. Variable-speed fans in air-handling units and in cooling towers, as well as variable-speed chiller compressors and pump motors, significantly reduce energy usage. Restricted-bypass laboratory fume hoods reduce airflow when hood sashes are closed. The college will pursue LEED Gold certification for the facility.

The $107 million cost for all three phases is $53 per sf less than an entirely new facility.

| Organization | Project Role |

|---|---|

|

CannonDesign

|

Architect

|

|

Bovis Lend Lease

|

Construction Manager

|

|

Christa Construction

|

General Contractor, Phase I

|

|

LP Ciminelli, Inc.

|

General Contractor, Phase II

|

|

Watts Architecture & Engineering P.C.

|

Civil and Environmental Engineers

|

|

CannonDesign

|

Structural and MEP Engineering; Lighting Design

|

|

Joy Kuebler Landscape Architect

|

Landscape Architect

|

|

Siemens

|

Controls

|

|

ThyssenKrupp Elevator

|

Elevators

|

|

Ventrol Air Handling Systems Inc.

|

Air Handlers

|

|

Air Terminal Units

|

|

|

ThermoFisher Scientific

|

Fume Hoods, Phase I

|

|

Mott Manufacturing

|

Fume Hoods, Phase II

|