The College of New Jersey (TCNJ) is designing new facilities to respond to the experiential, project team-based learning paradigms set forth in today’s cross-disciplinary agenda for science, technology, engineering, and math. With one new construction and a renovation project underway, TCNJ hopes to reap the same benefits realized at other institutions, which experienced increased applicants, enrollment, and STEM majors, as well as more effective pedagogies and greater research output.

The projects are the outgrowth of a long-term transformation that began 20 years ago with a name change from Trenton State College. Bucking the trend toward expanding into a mega-campus, TCNJ decided to downsize its student body (full-time undergraduate enrollment now stands at approximately 6,500) and deepen its commitment to the teacher-scholar model. In honing its program focus and making itself more selective, over the past two decades the college has boosted its freshman-to-sophomore retention rate to 93 percent, considerably higher than the 2012 national average of 79 percent, and now boasts an 87 percent graduation rate, which was nationally at 59 percent in 2012.

One physical manifestation of this narrow-casting is the creation of a STEM complex. The initiative includes construction of an 88,960-sf dedicated STEM building, which recently broke ground; and refurbishing the existing Armstrong Hall, currently home to the School of Engineering, which will see its mechanical and biomedical engineering departments relocated to the STEM facility. These and other buildings in the complex will all be renovated and connected to foster highly prized cross-disciplinary interaction.

“We really want to be promoting deeply engaging interactions with students,” says Steven Schreiner, dean of TCNJ’s School of Engineering. “Our aim is that the new and renovated facilities will further increase our competitiveness, and we will get an even higher-profile student coming in, as well as more industry interaction with the college.”

Seven STEM Facilities Goals

In making project design decisions, TCNJ relied on guidance from EYP Architecture & Engineering, which has done a deep-dive analysis of the 300-plus teaching labs it designed over the past decade. While the labs fall into five basic types—introductory, advanced, interdisciplinary, multidisciplinary, and project-based—says EYP architect Melissa Burns, the projects all share a number of goals:

- Create an environment that is energy efficient, sustainable, and satisfying.

- Attract the desired type or quantity of students and faculty.

- Enhance the effectiveness of STEM teaching and research.

- Advance student and faculty research, especially across disciplines.

- Create a welcoming place to congregate, study, and learn.

- Promote interaction among students and faculty.

- Enhance students’ interest and attitude toward STEM fields.

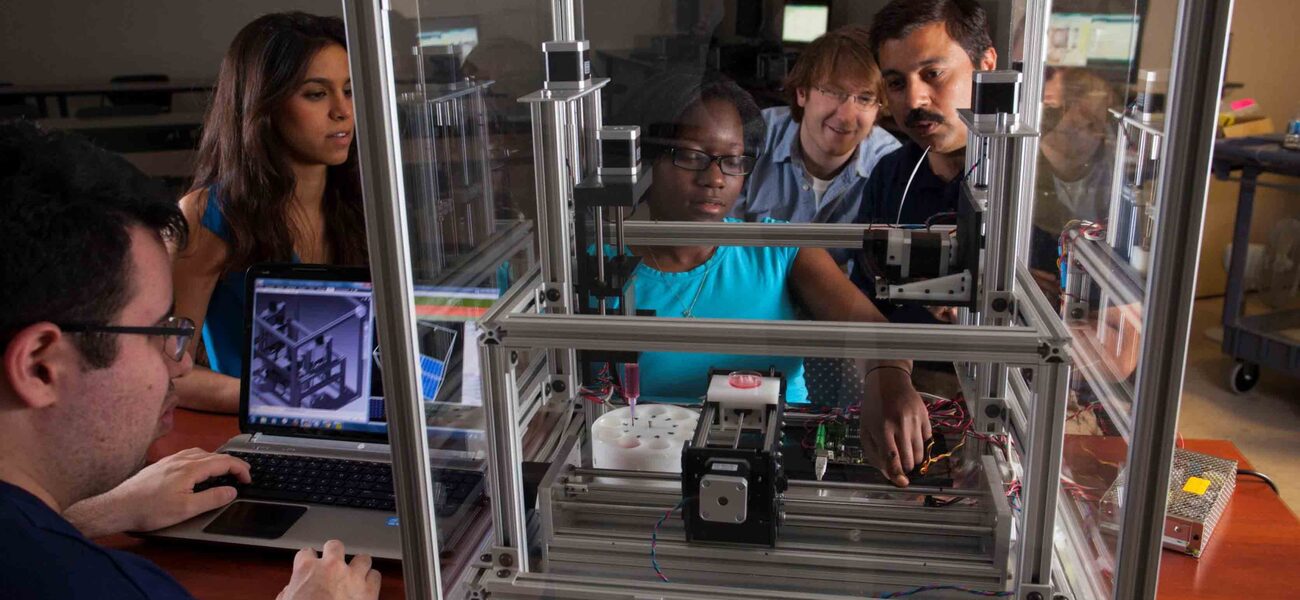

TCNJ’s projects incorporate spaces and features that meet these goals. For example, many of the teaching and research labs have glass walls along a main corridor—“storefront construction”—to afford visibility for passers-by, creating the opportunity to attract student attention and increase interest in STEM fields.

“Currently, biomedical engineering in Armstrong Hall is squirreled away in back corners,” says Burns. “Showing off the work that faculty are doing, and the ability to work with students as they are progressing in that research, are really important to TCNJ. Storefront construction helps to demystify science while also showing the connection and the experimentation that is happening on both the faculty and student side.”

Going Beyond the Goals

In several cases, TCNJ takes STEM learning spaces one step further. As an example, Burns references the EYP-designed Academic Innovation Center at Bryant University, R.I., and the Center for the Sciences at Trinity University, Texas. These facilities include a trio of space types in relatively close proximity that reflect the progression of student work: thinking space, in a comfortable, lounge-like setting; modeling space, often in a computer lab, using digital tools for virtual modeling; and making space, with a wide range of tools for brainstorming and prototyping.

The TCNJ STEM building has similar thinking, modeling, and making spaces. What is distinctive is the support system around the spaces that affords a higher level of prototyping and assembly. A significant leap is the finishing room, an innovative component that will allow engineering students to work with an expanded range of materials, such as carbon fiber. Due to concerns about particulate migration and the need for protective equipment, this type of work had customarily been outsourced.

“There are some really innovative components of support in the finishing room that we had not done before,” says Burns. “This required thinking about how different pieces of materials would be used and the development of safety protocols, as well as equipment access and clearance.”

Another unusual component is the automotive paint booth. One regular student project is a 20-foot long solar boat that needs to be painted.

“You can’t do that in a small paint booth like you would normally do for a small project,” she says. “We made the paint room flexible enough to paint the large solar boat or to paint multiple smaller projects at different stations.”

These additional capabilities are key to meeting the goal of advancing student and faculty research, especially across disciplines.

“We have such a variety of projects that I wanted to make sure we have the ability to realize all the complex designs in-house as much as possible,” says Schreiner. “Students should have the flexibility to branch out so they are not so constrained in their designs. In addition, bringing things like the carbon fiber work in-house helps us become a resource for industry. The finishing rooms are so important to us because we don’t have those capabilities now.”

Quantifying the Impact

As part of its study of the teaching labs it has designed, EYP sought to assess the quantitative impact of the labs on the respective institutions.

“Tying a building to university goals and then measuring how well it meets those goals proves to the administration that there was a return on investment,” says Toni Loiacano, an EYP architect who specializes in academic planning and design.

Partnering with Royce Singleton, an emeritus professor of social psychology at College of the Holy Cross, in Worcester, Mass., EYP applied a three-part social science methodology—pre- and post-occupancy surveys, administrative data analysis, and observational data—to document how various buildings fared in meeting the seven STEM facilities goals.

In particular, EYP took a close look at three goals: attracting students and faculty, enhancing the effectiveness of STEM teaching, and enhancing research productivity.

The “attracting desired students and faculty” goal was further sub-divided into three questions: Has the number of applicants increased? Is the STEM building a motivator to apply? Does the school now have more STEM majors?

Hamilton College’s Taylor Science Center, which opened in 2006, was one of the facilities under review. According to Loiacano, even before construction of the new building, Hamilton had instituted a major change by switching to an open curriculum, in 2000. Looking at the college’s admissions data from 1998 to 2014, which includes both “disruptors,” the team found an average increase of 500 applicants per year. The quest to become a more selective institution is also in evidence, with yield increasing from 25 percent to 35 percent.

The positive influence of the STEM building on applicants is evident in students’ rating the quality of Hamilton’s academic facilities as higher than peer institutions, and identifying them as a “very important” factor in their decision to enroll.

The number of STEM majors has also gone up. Before the new building in 2006, STEM majors constituted roughly 30 percent of the Hamilton graduating class. The proportion has been steadily increasing to its current level of about 40 percent—all while maintaining an equivalent number of students.

Is STEM teaching more effective with the new space? In response, Loiacano cites major post-occupancy surveys performed for two other clients, College of the Holy Cross and Wheaton College in Massachusetts.

“More than half the faculty report that they have changed their pedagogy, 84 percent believe there is greater flexibility in accommodating diverse strategies and styles, and 92 percent believe the facilities provide a better quality teaching environment,” she says.

The post-occupancy data also answers 11 questions relating to the impact of the new labs on research productivity.

“Overall, more than half the faculty reported that the research output was greater in the new labs versus old labs, and 65 percent of faculty reported enhanced efficiency, noting they were able to do research more quickly in their laboratories,” says Loiacano.

The survey results reinforce the design decisions made at TCNJ to equip its new STEM building and renovated engineering building with a gamut of space types that address the needs of both individual disciplines and the interactive collaborations that span multiple areas of research. Adjacencies that encourage connections, a progression of labs that follows the project flow, and the combination of formal and informal teaching spaces to promote inspiration and experimentation have all been guiding principles.

“We want lots of thinking and lots of interactive design going on across the school,” concludes Schreiner.

By Nicole Zaro Stahl