All lab work—experiments, equipment usage, write-ups—occurs on countertops, but these flat horizontal surfaces are rapidly changing. “Today, lab work surfaces need to be adaptable, flexible, ergonomic, mobile, reconfigurable, versatile, sustainable, design-oriented, aesthetically pleasing, cost-effective, and easy to install,” says Arnulf Penker, president of FunderMax, a designer and producer of wood-based materials and compact laminates in St. Veit an der Glan, Austria.

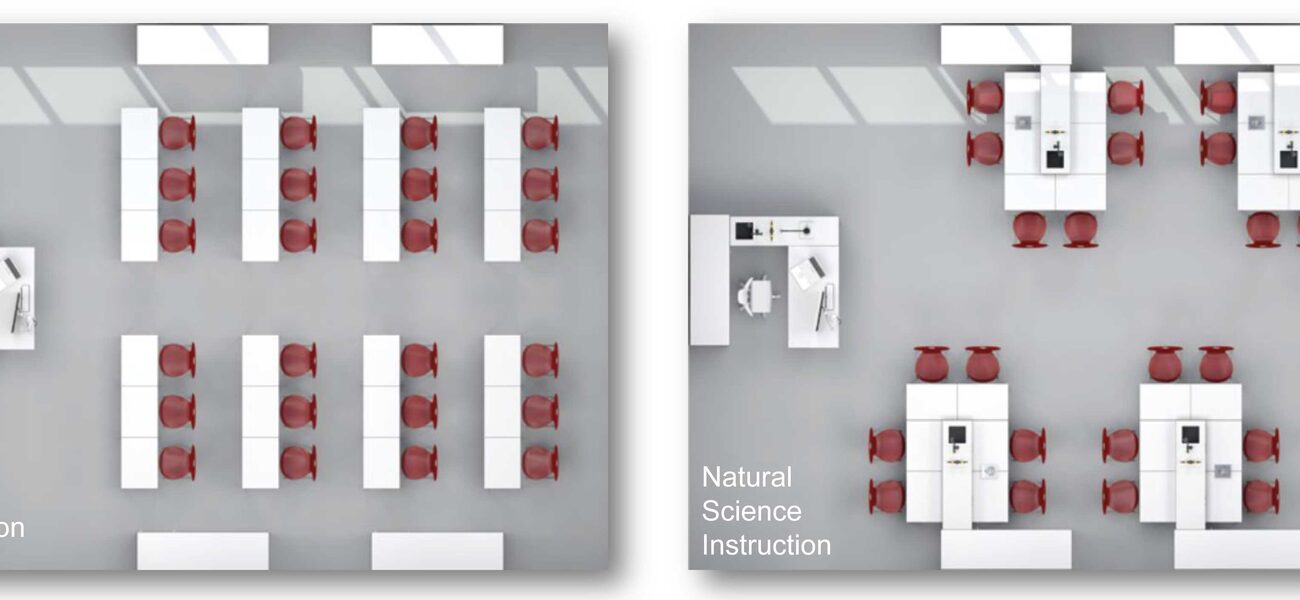

The trend toward “science on display” is increasing demand for surfaces that are attractive as well as functional. Convergence of teaching and research spaces has increased demand for surfaces that are suitable for multiple research types; increased demand for shareable and easily convertible spaces requires that these materials be light enough to make lab furniture portable. The trend toward team-based research, by increasing the square footage devoted to collaboration and collision spaces, has reduced the net square footage of laboratory space, making it even more important to wring maximum utility from every square foot.

Laboratory work surfaces are also being shaped by technology, sustainability, and economics. Laboratories for process simulation and data work, and the advent of technology-enhanced active learning in the teaching laboratory, has increased requirements for connectivity, flexibility, and visual warmth. LEED and other sustainability standards incentivize materials that are sustainably produced, recyclable, reusable, and low-emitting. And budget tightening and schedule compression demand lab surfaces that are easier to fabricate on site, install, and alter.

Important Properties of Lab Surfaces

Chemical- and stain-resistant work surfaces have always been essential in wet labs. But chemical resistance is becoming important in other lab types. “Labs are being used for different types of research over their lifespan,” says Penker. “Even if a laboratory is not being used now for wet chemistry, it may be someday.”

Mechanical properties such as scratch, impact, and abrasion resistance are also becoming more important. “Mechanical performance is now rivaling chemical resistance as a consideration in today’s world of laboratory furniture that is flexible, mobile, adaptable, and reconfigurable,” says Penker. “In maker spaces and project labs, tools are used on the workbench, heavy equipment is moved, and work surfaces need to be able to stand up to that kind of abuse.”

Thermal properties must also be considered. When Bunsen burners will be used, for example, a surface should be chosen that will not blister, crack, or discolor under a brief flame exposure. “Thermal shock resistance is also important, for example if you are using dry ice to cool equipment or experiments,” says Penker.

Flatness and thickness tolerances are important for overall safety. “You want materials that have low tolerances and are very flat, so that the joints line up,” says Penker. “You don’t want someone breaking a container of chemicals due to a defect in a work surface.”

Porosity is a particularly important consideration for laboratories requiring disinfection, and it also determines overall cleanability. Water absorption capacity is important in wet environments.

Sustainable design is also shaping work surfaces. Those with a favorable environmental product declaration (EPD)—certifying that the material is environmentally low-impact, from production through use, reuse, and end-of-life disposal—can contribute to LEED points, as can low-VOC materials. “The third-party environmental product declaration is a new important tool in the industry to determine, in a very transparent way, a product’s sustainability,” says Penker.

Metrics

Two chief metrics to consider when selecting materials—in addition to each material’s particular advantages—are material weight and installed cost. Weight is a product of both the material density and the thicknesses typically specified in labs. In environments requiring mobile, adaptable furniture, materials should be strong and yet relatively lightweight so they can be moved easily. In general, lighter materials are also more sustainable.

Installed cost includes both the cost of the material itself and the cost to install it. Installation costs hinge on ease of installation—the cost of fabricating and installing the product on the site—as well as sheet size, which determines how much material will be cut away and discarded. Machinability is a key factor.

The Top Three Laboratory Work Surface Materials

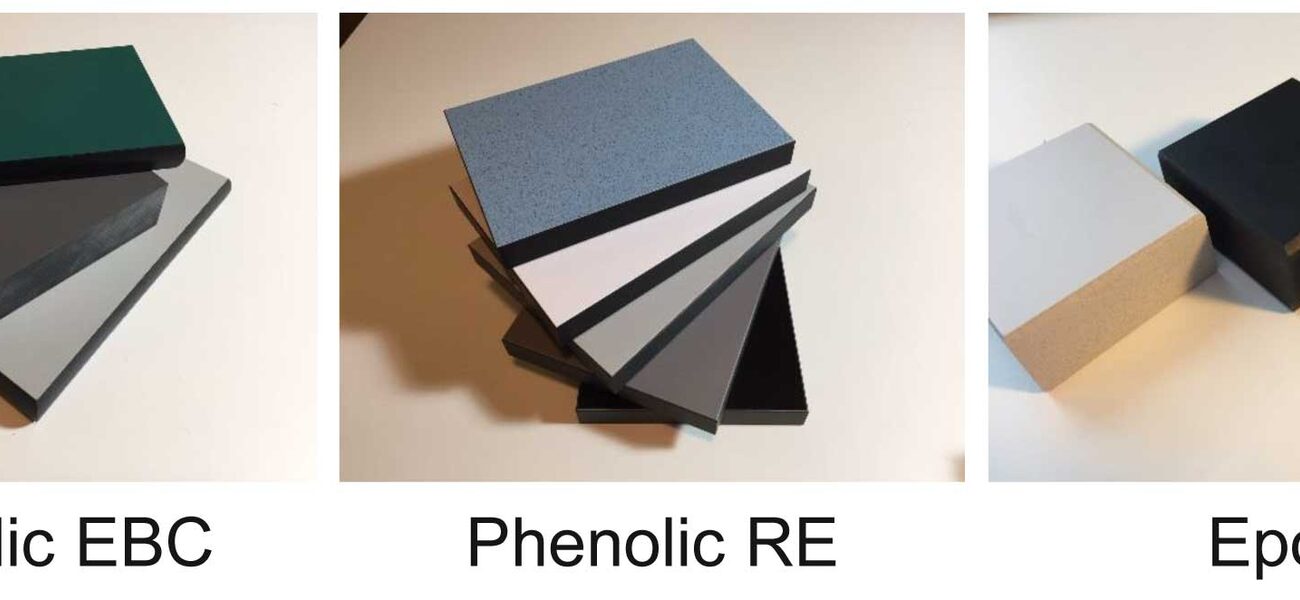

The three products most commonly specified for laboratory work surfaces are epoxy resin, phenolic resin compact panels with electron-beam curing (EBC) technology, and phenolic resin compact panels with RE (resistance) double-hardening technology. These highly versatile materials are resilient, lightweight, affordable, and attractive; the phenolic resins are also relatively sustainable. “As the sciences continue to converge and mix, lab-grade phenolics and epoxy resin are the most versatile and have the most universal applications,” says Penker.

- Epoxy resin, the most commonly specified material, is made from silica and resin poured into a form and baked. Although the most heat-resistant of the three, it is less adept at resisting thermal shock. It is also less easy to install and less sustainable than the phenolic resin compact panels.

- Phenolic resin compact panels with EBC technology, the second-most-specified material in labs today, is a wood-fiber-based product cured in phenolic resin and pressed in a hot press. It is extremely resistant to chemicals and thermal shock, but not to high heat. It is easy to install and relatively sustainable.

- Phenolic resin compact panels with RE double-hardening technology are a relatively new arrival in the marketplace. Similar in composition to the EBC phenolic resin panels, this material features an acrylic layer that gives it a formidable chemical resistance; of the top three, it is the only product that is resistant to hydrofluoric acid. It is also the most resistant to scratches and abrasion. Although resistant to thermal shock, its heat resistance is not as strong. Sustainable and very easy to install, it offers the best performance/cost ratio.

Snazzy, Light-Duty Materials

Where chemical and mechanical resilience is not necessary, these materials offer aesthetic flexibility and visual impact at a low cost:

- General-purpose phenolic panels, also known as compact laminate, incorporate the same wood-fiber-based core as the lab-grade EBC and RE phenolic panels, without the chemical- and mechanical-damage-resistant surface layer. Ease of installation, machinability, light weight, affordability, and a wide range of color options make this material a good choice where chemicals and heavy equipment will not be present.

- Plastic laminate, a wood-based material with a thin laminated surface of melamine phenolic resin, is also easy to install and machine, available in a rainbow of colors and designs, and less expensive than general-purpose phenolic panels. Entirely lacking in chemical and heat resistance and susceptible to scratching and abrasion, its strengths lie in its aesthetics, easy machinability, and low cost.

- Solid-surface products, such as Corian®, are stone-like products that offer little chemical resistance. Popular in Latin America, these products offer good machinability and repairability and come in many colors.

Toughies

These specialty materials with specific strengths can sometimes be worth the extra cost.

- Ceramic is the toughest benchtop material, able to withstand virtually any chemical or mechanical insult, as well as extremely high heat. But these benefits come at a high cost: The material is heavy, non-machinable, and difficult to install. Design possibilities are limited, and sustainability isn’t great.

- Granite and marble, because they are natural materials, have a much better sustainability profile than ceramic, and their resistance to scratch and abrasion rivals that of ceramic. But because they are porous, their chemical and microbial resistance falls far short, and, like ceramic, these materials are heavy, expensive, non-machinable, and difficult to install.

- Stainless steel is the most heat-resistant and thermal-shock-resistant material, and its easy disinfectability makes it ideal for food and beverage processing settings. However, its chemical resistance is spotty, it’s expensive, and it isn’t very machinable or easy to install.

- Polypropylene and polyvinyl chloride (PVC) provide excellent acid resistance but are mechanically weak and are generally better suited for vertical rather than horizontal surfaces.

- Wood butcher block, although it offers very little chemical or microbial resistance, is a great material for maker spaces and engineering project labs because of its ability to withstand mechanical abuse. Made of natural wood, it is visually appealing, machinable, and sustainable.

By Deborah Kreuze