The new engineering building at the University of Alaska Fairbanks (UAF) not only relieves overcrowding at the College of Engineering and Mines, it also cultivates interdisciplinary research and entrepreneurship, with open, flexible labs; the incorporation of computer science; and a direct link to the School of Management. These features combine to create an environment where students learn hands on how to solve problems and speed their ideas to market, in a facility made transparent with extensive glazing, both inside and out.

“We wanted to create a design that enriches entrepreneurship by connecting student groups,” says Douglas Goering, Ph.D., P.E., dean of the College of Engineering and Mines. “One of the ideas was to make a strong connection between engineering and business, and I think we achieved that.”

UAF is a land, sea, and space grant institution and an R2 research university; engineering has a particular connection with the space grant piece. About 1,000 undergraduate, graduate, and doctoral students are enrolled in the College of Engineering and Mines, which includes six academic departments and the Institute of Northern Engineering, its research arm. Its existing facility, Duckering, was built in 1962, with a major addition in the mid-1980s and a renovation in 2000. That 140,000-sf building served 500 students in 2005, but the number continued to grow until it surpassed 1,200 in 2015, putting stress on the student laboratories, machine shop, and research spaces. A subsequent drop in enrollment of petroleum engineers has brought the number back to 1,000. The new 120,000-sf Engineering Learning and Innovation Facility (ELIF), is designed to accommodate the current enrollment.

“This is the last new engineering building we’ll see on this campus in the next 30 years or so,” says Goering. “We don’t want to be crowded, but we don’t want to see an empty space, either. We’re walking that tightrope, like everybody else does.”

The college includes programs in civil, environmental, electrical/computer, geological, mechanical, mining, and petroleum engineering. ELIF includes a chemical engineering lab in anticipation of adding that program in the future. Computer science, which is more software-based than computer engineering, was originally part of the science college. It was moved over to engineering in 2010, but was located in another building 10 blocks away. And the mineral processing lab was located in an old agricultural barn off campus.

“This new facility will allow us to coalesce these other branch engineering programs,” says Goering. “Integrating computer science into the new complex was part of the discussion surrounding the design.”

Duckering will be renovated to accommodate some of these programs. Computer science will be located there, and the old machine shop will be converted into field research equipment assembly room.

A New Vision: More Visibility

The university wanted the new engineering space to not only add square footage to the program, but to also provide new opportunities for interdisciplinary collaboration and entrepreneurship, and to make the work going on there visible to people inside the building and on campus. The first issue was where to put it. The existing engineering building and the management school are both located on a major campus drive. The solution was to sandwich the new building between them, connecting all three structures with a two-and-a-half-story atrium, which has become a hub of activity for both management and engineering students.

Often the most spectacular space in an engineering building is the high bay, and at UAF, the high bay is completely enclosed in glass, making it also the most visible space, from campus as well as from the lobby and the main second- and third-floor corridors.

“One of the features of the building that we had to maintain was some visibility from the quad,” explains Goering. “The chancellor was very insistent that we maintain a visual tunnel through the building.”

From the quad, you can see into the atrium, behind which is the high bay, which lines up perfectly with the sunrise on the equinox.

The building also contains a multitude of smaller glassed-in work areas to expose students and researchers to each other’s projects. Many of the building’s own mechanical systems are on display, as well: A touch panel is linked to building energy systems, and part of the floor slab heating system is exposed.

Hands-On Active Learning

Students are encouraged to not only design their innovations, but to build them.

“The students benefit tremendously from hands-on experiences, and we really wanted to be able to maintain it, but our growth in student numbers was compromising that capability quite a bit,” says Goering.

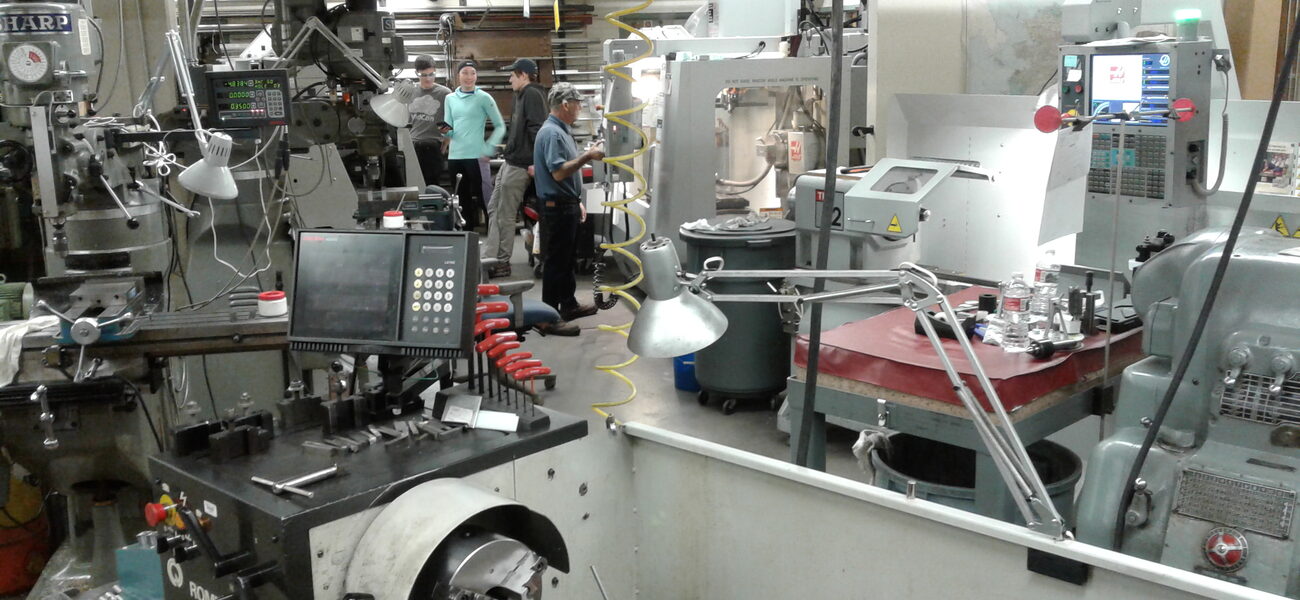

The ELIF building increases the size of the machine shop from 1,000 to 1,500 sf, and raises the ceiling substantially. That, combined with a variety of other maker spaces throughout the building, provides more experimental opportunities to both students and faculty.

The University of Alaska is the only university in the world that has its own sounding rocket launch range, where students design and launch payloads into the ionosphere. Over the last five years, they have advanced to designing satellites; students launched their first satellite into orbit about two years ago. And civil engineering students compete nationally on a steel bridge team. “One of the reasons our students do well on this is because they have the space to not only design these bridges but manufacture the parts to the bridge using computer-automated machine tools, and to cut the steel and weld it. That makes a huge difference,” he says.

And then there’s the high bay structural lab, measuring 125 by 25 feet and 48 feet high, outfitted with a bright yellow 30-ton overhead crane. The center of the room—100 by 24 feet of it—is a strong floor constructed of 4 feet of super-reinforced concrete, with anchors on 4-by-4-foot centers that can be tensioned to 300 kips (300,000 pounds). One use of the space, mostly by graduate students and faculty, will be to test large structures for the U.S. Department of Transportation and for aerospace manufacturers to do cold-weather work. For example, it may be used to test bridge girders, which use a unique construction in Alaska because of the extreme cold. The university is also one of only six Federal Aviation Administration test centers for drones in the country.

Adjacent to the atrium is an assignable room for collaborative engineering work—a glass-enclosed maker space of about 750 sf, full of hand tools and 3-D printers. “So far, I would say that it has been organized chaos, which is kind of what we hoped for,” says Goering. “It has been very well used.” In one semester, it was used primarily by two groups of students, one designing a new kind of wheelchair and one working on a lightweight aircraft. They were able to work around each other and got along fine, says Goering.

The new machine shop is centrally located on the first floor, with several overhead doors entering into the high bay. Adjacent to the machine shop are two engineering special projects labs, which are essentially maker spaces; the civil engineering students will likely commandeer one of those rooms for the bridge construction project. There is also an adjacent wood shop, welding shop, and a small foundry, as well as a large plasma cutter.

The building is also equipped with a state-of-the-art cold room complex in the basement, including one ultra-cold room that is capable of maintaining a constant minus 55 degrees Celsius to within a fraction of a degree. That can be used to research the issue of icing on aircraft, for example, and Goering is contemplating research in traction strategies.

All of the labs in the new building are “flex labs,” strategically named so that no one department or team can lay claim to them. “We didn’t want to give anyone the idea that it was their space,” says Goering.

The NASA Space Grant Program, however, has been associated with the university for 20 years and will likely “own” its own lab, which was expanded in the new building to accommodate payload and CubeSat (miniature satellite) testing. Adjacent office space is available for faculty and graduate students working with the program.

Collaborative Research and Student Work Areas

The building is designed to facilitate collaboration, and to be flexible for changing requirements. Every floor has multiple informal student study areas, some of which are glassed in for group study and some are open. Each is outfitted with projection capabilities using ShareLinkTM technology. Student spaces and classrooms are equipped to project onto screens from tablets, laptops, and handheld devices.

Classroom furniture can easily be rearranged to support a “flipped” classroom. Tables in the new building are on casters. There are two large screens in the front of the classroom, and the walls are lined with hanging monitors connected wirelessly. There are no computers in the classrooms, because students typically own their own laptop and tablet.

Teaching labs also are design to be adaptable: Lab benches are connected via ceiling panels, with overhead utilities, and flexible lighting, hoods, and snorkels for chemical and bench work. The chemical engineering lab, for example, is being used to teach other classes until chemical engineering is added to the program.

For collaborative research, the building features open research suites on floors two and three, each including six separate assignable research bays. The main part of the lab is fitted out with all mobile and adjustable casework, with the exception of the fixed support areas—sink, prep, and storage—along the inside wall. As in the teaching labs, utilities drop down from the ceiling, and not all benches are equipped with hoods and snorkels.

“I suspect with engineering research the way it is that some of those benches are going to be almost immediately removed,” says Goering. “We have a civil engineer with funding from the federal Department of Transportation to look at transportation safety. He wants to build a 3D visualization system, and he doesn’t need a lab bench for that. He needs a big space for screens and a visualization system.”

Sustainability Features

The temperature in Fairbanks can fluctuate by nearly 100 degrees Fahrenheit over the course of just a few days, so energy efficiency is critical with the new building. The location itself offers some relief, with two if its “outside” walls erected up against the adjacent buildings.

The building uses slab heat, harnessing waste heat captured from the power plant at 100 degrees Fahrenheit. That is not hot enough for a standard heating system, but a slab heat system can make use of low-temperature waste heat. The power supply is supplemented with 12,000 kWh per year from a solar array installed on the south wall.

By Lisa Wesel