Roads filled with driverless cars, ethical decisions left up to smart machines, and robots that help paralyzed patients walk again sound like elements of a best-selling sci-fi thriller, but these are just a few of the research projects planned at the University of Michigan’s new Ford Motor Company Robotics Building. Scheduled to open in early 2020 at the school’s main campus in Ann Arbor, it is the university’s first public-private facility partnership. The collaboration offers insight into facility planning and industry partnership models that are emerging to support artificial intelligence (AI) and robotics innovation, recruit top talent, and prepare new graduates with the skills needed to thrive in this burgeoning industry.

Deborah Mero, senior executive director of resource planning and management at U-M’s College of Engineering, worked with the team responsible for the university’s collaboration with Ford. Mero explains that Ford offered to partner with the university, allowing the building to ultimately grow into a $75 million, 140,000-sf building, designed by Harley Ellis Devereaux.

Facility as a Recruiting Tool

All labs will be visible from the new building’s four-story main atrium, which is designed to host the university’s recruiting and fundraising events, as well as corporate events held by Ford.

“We designed the facility to attract the top AI and robotics talent on the planet,” says Mero. “It will be a true example of ‘science on display,’ since all of the labs and testing areas will be visible to anyone touring the building and grounds, giving potential students and donors a first-hand look at the research underway.”

“I'm excited about having collocated robotics and community spaces, and very much looking forward to having the students learn more from each other with shared lab space and by being in proximity to one another,” says Brent Gillespie, professor of mechanical engineering.

“We’ll have many labs, classrooms and other spaces for collaboration,” adds Katherine Skinner, one of the first U-M robotics Ph.D. candidates. “Most importantly, robotics students will finally have a home here on North Campus.”

In addition, visitors to the new building may witness robots roaming freely on all floors and even calling the elevators themselves. The robots will be able to move independently, guided by a tool called AprilTags, an open-source visual tag system developed by U-M’s Edwin Olson, associate professor of computer science and engineering. “April” stands for autonomy, perception, robotics, interface, and learning, and the tags are the 2D printed barcodes, similar to QR codes, that guide the robots.

“The AprilTags can be created from an ordinary printer and placed throughout the building. They’ll serve as a combination of street signs and lane markers for our robots, allowing them to navigate around the building themselves,” says Mero.

Most of the tags will not be obvious to visitors; robots will “see” them using detection software that allows them to compute the precise 3D position, orientation, and identity of the tags relative to their camera.

Testing Autonomy in the Air, on Roads, and in the Sea

The M-Air Outdoor Test Facility provides 9,600 sf of drone research space, enclosed in four-story netted exterior walls that form a fly zone. Located adjacent to the new Ford Robotics Building, M-Air opened in 2018 and is used specifically to test autonomous aerial vehicles.

“With this facility, we can pursue aggressive educational and research flight projects that involve high risk of fly-away or loss-of-control—and in realistic wind, lighting, and sensor conditions,” says Ella Atkins, professor of aerospace engineering. “We also can begin to better understand operational risks associated with real-world outdoor flights with no real risk to people or other aircraft outside the net.”

Mero says that safety concerns are paramount, because M-Air is within flight patterns used by the university’s main hospital, and that by enclosing it, drone researchers can conduct tests freely without concern for the hospital’s emergency helicopter and other aircraft.

Just down the street from M-Air and the Ford Robotics Building is the Mcity Test Facility, a 32-acre site featuring 16 acres of roads and traffic infrastructure, creating a small-scale urban and suburban environment. The simulated city includes two-story building façades, roundabouts, ramps, and a railroad crossing, as well as mock pedestrians to study pedestrian avoidance technologies.

Finally, across the street from the new Ford Robotics Building, is the Department of Naval Architecture and Marine Engineering, where faculty and students research new robotics technology to navigate, communicate, map, and analyze in underwater environments. To enable this research, the Marine Hydrodynamics Lab offers a wave and modeling tank over 100 meters long. A new naval robotics building is in the planning stage for this department.

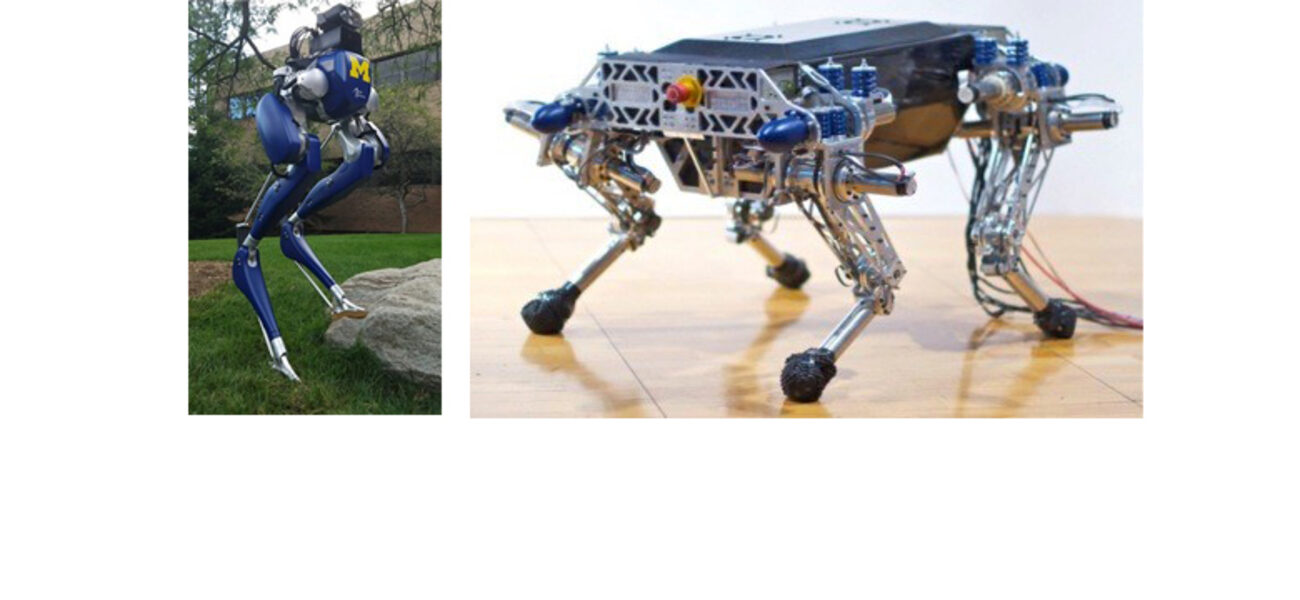

Walking Robots Help with Physical Rehabilitation

In addition to the autonomous testing facilities, other key infrastructure features of the new Ford Robotics Building include: 10 labs wired for 10 gigabytes-per-second Ethernet, and infrastructure that will allow them to go to 100 gigabytes per second for future needs; a high bay garage for testing self-driving vehicles; open collaboration areas; an outdoor obstacle course with multiple surfaces; an indoor three-story flying and walking lab; and a Rehab Robotics lab focused on analyzing human gait for robotics used in physical rehabilitation.

“One of the features that makes the new lab unique is a 6-foot Stewart Platform robot hidden within a pit in the floor,” says Elliott Rouse, assistant professor of mechanical engineering. “The platform’s surface can move in all directions and rotations, enabling it to apply disturbances to the human body during locomotion, which will inform our research and enable better-performing, more life-like artificial limbs and bipedal robots.”

Partnering with Ford

The Ford/U-M Strategic Alliance is the university’s most expansive industry research collaboration, involving faculty in multiple schools and colleges on the Ann Arbor and Dearborn campuses. The research performed through this alliance contributes significantly to the goal of making mobility safer and smarter through autonomy. And the partnership manifests itself in people, too. Many of U-M’s students go on to careers at Ford. During the 2015-2016 academic year alone, Ford hired 160 students and alumni for internships or full-time positions.

This building strengthens that relationship and marks the first time that Ford engineers will have a permanent presence on campus.

“Since the university was not used to playing the role of landlord, we hired an outside accounting firm to determine the fair market value of the lease,” says Mero, who added that the university required specific approval from the board of regents to move forward with the project, sign the long-term lease, and issue taxable bonds for the building.

“As a public university, we needed to ensure that all elements of this partnership were very transparent and could stand up to public scrutiny,” says Mero.

The company also contributed $15 million to expedite construction, for which the university named the building in the company’s honor.

“Having Ford on campus will bring increased opportunities for Ford engineers to interact with students by serving as mentors and instructors,” said Jessy Grizzle, the director of Michigan Robotics and the Elmer G. Gilbert Distinguished University Professor of Engineering. “It will also offer all students more research and impromptu networking opportunities. In particular, U-M student teams will really benefit from having them in the building.”

Offering Advice for Similar Projects

Mero concludes that although public-private partnerships require careful consideration and planning with an added stakeholder, they enable deeper investments in advanced research facilities, resulting in successes such as the Ford Robotics Building. In consideration of similar projects, she points to three key strategies:

Identify your stakeholders early and keep checking back to make sure they are all still in alignment throughout the project. Ensuring that all partners who have a seat at the table can help anticipate and address new ideas and challenges as they arise.

- A public-private partnership must be an arms-length agreement that will stand up to public scrutiny. Consider lease agreements, intellectual property, and tax implications, while also balancing those against the benefits that these partnerships can bring to both the educational experience and research potential.

- Think about how to integrate the corporate and academic cultures. Consider creating a committee that will include all of the stakeholders to try to anticipate and address any concerns upfront.

- Be prepared to respond to other public companies who want to get involved or start new partnerships.

“Once other companies learned of our agreement with Ford, we heard from many that were interested in exploring similar opportunities,” says Mero. “For now, though, we’ve had to communicate that we are in a pilot phase, and need to learn from this experience before engaging in any other new partnerships.”

By Amy Cammell

| Organization | Project Role |

|---|---|

|

HED

|

Architect

|