Duke University is laying claim to the future with a new $115 million engineering facility, the Wilkinson Building. The flexible, adaptable structure was completed in November 2020, and opened for students and researchers in January. Space for engineering education and research expands with 150,000 gsf on five levels. That translates into a 25 percent increase in the university’s engineering footprint and 50 percent more teaching and student program space for engineering.

To Mitchell Vann, director of facilities, infrastructure, and safety for the Duke University Pratt School of Engineering in Durham, N.C., the project is nothing short of “transformative.”

Located at 534 Research Drive, the Wilkinson Building practically rubs elbows with the Duke Health and School of Medicine campus, the historic Duke campus, and three other engineering buildings: the Fitzpatrick Center for Interdisciplinary Engineering, Medicine and Applied Sciences, Hudson Hall and the Nello L. Teer Building. “It’s really a hub of all those different areas,” says Vann, who has been involved with the project “since day one.”

This new construction frees up 30,000 sf in the current engineering buildings “to renovate, reconfigure and backfill,” says Vann, “and that’s a big deal for us. That’s a lot of real estate” that can, over time, be transformed into new and reconfigured student spaces, meeting and study rooms, additional teaching labs, and other educational spaces.

The University has already begun planning for the reuse and reconfiguration of many of those spaces, for other faculty research clusters to be collocated and additional space for students to work, study, and decompress.

But Duke’s engineering school is laser-focused on the new facility, designed by architects at Bohlin Cywinski Jackson.

The grounds surrounding the structure offer students, faculty, and staff a “plaza with a ‘pedestrianized’ streetscape, steps, sitting walls, shade, and a very generous park-like setting as opportunities for gatherings and for tours to begin,” once campus COVID-19 restrictions ease, says Vann, “and even for things like design fairs, where students will be able to show off their work, creative designs and projects in the out-of-doors.”

The main entrance opens onto the main level in an area Vann calls “a wedge. It’s a very generous, deep space that is a collaboration space, a gathering space, an entrance space.” At one end is a coffee bar and lobby that serves as a hub for interactions, which is complemented by an upper stairway with views all the way to the top floor, inviting mingling among the levels. Wide steps lead down to the Learning Commons—or study space—where teaching assistants work with individual students. Conference rooms also are available for consultation.

Each of the university’s four engineering departments—biomedical, civil and environmental, electrical and computer, and mechanical and materials science—has a design lab, three on the lower level and the other on the main.

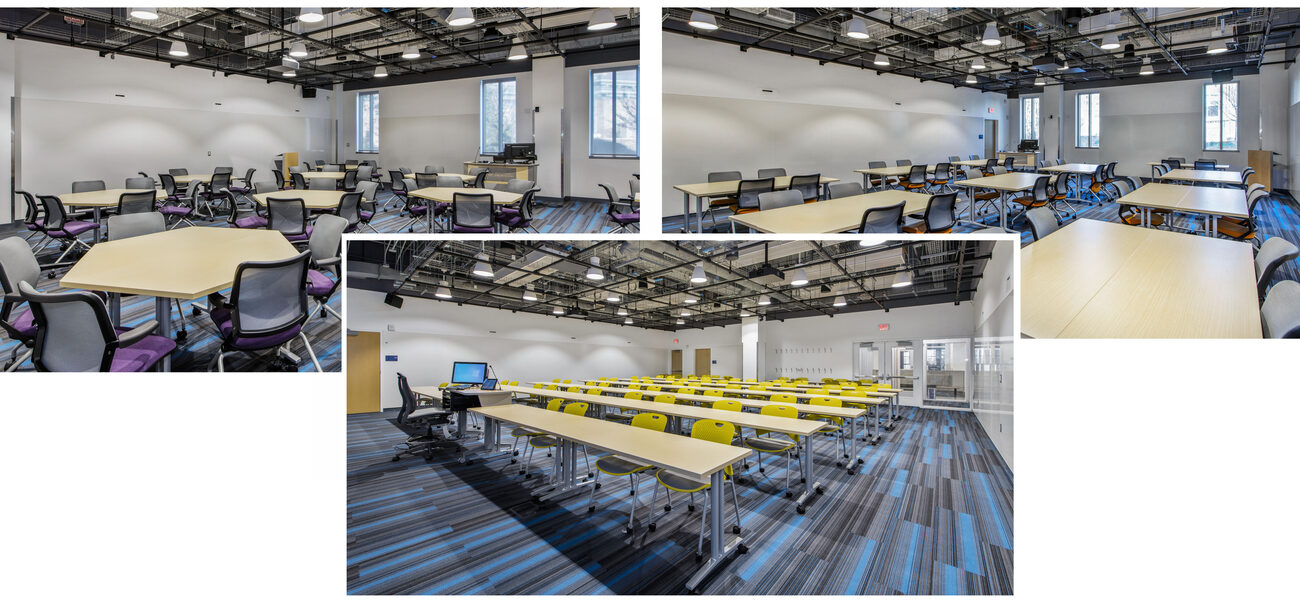

Most of the education takes place on the main and lower levels, including two 40-seat and two 60-seat active learning classrooms on the main level that feature:

- flat-floor classrooms with flexible furniture configurations that allow students to listen to professors and then work together to collaborate with classmates

- raised floors of about 4 inches high that incorporate floor boxes for power and data. “We can move those floor boxes around over time to accommodate different kinds of furniture and room sets,” says Vann.

- An overhead pipe grid that makes it possible to reconfigure the space in terms of microphones, speakers, or short-throw projectors; or to add electrical power from the ceiling.

“The ability to morph those rooms into different configurations is huge,” says Vann.

Generous space was designed to accommodate pedagogical changes brought about by the concept of the “flipped classroom.” Students can catch lectures on video outside the classroom, allowing them to spend class time efficiently, working together as teams on various projects. They act as leaders and collaborators, learning valuable lessons while working with others in a diverse environment to solve real-world engineering challenges. Duke Engineering considers this interaction with “teammates” to be a particularly important part of a young engineer’s development.

Although they may seem a bit retro, whiteboards play a role in the active-learning classrooms. With large screens and projection placed in front of the classroom windows, the remaining three walls accommodate a large porcelain writing surface, from corner to corner and floor to 7 feet high. Short-throw projectors can take advantage of the walls, too.

Engineer as Entrepreneur

A highlight of the lower level is the 200-seat auditorium. The design team considered investing in a room that could be divided, but decided that the engineering school would make greater use of a space that could accommodate large classes, seminars, group work, presentations, panel discussions, and demonstrations.

While such large gatherings are currently on hiatus due to the pandemic, the auditorium’s generous size has allowed ample social distancing for the limited-capacity classes held there during its inaugural semester.

One intriguing program sure to benefit from the auditorium is Duke Engineering Entrepreneurship (Duke EngEn), which helps student engineers develop technological innovations and bring their solutions to society by launching new products, services, and companies.

Near the auditorium is a glass-enclosed entrepreneurship center—to host classes, seminars, and Entrepreneurs-in-Residence sessions—plus small breakout rooms, where students can deliver their pitch to one or a group of investors in person or online, before taking their presentation to larger audiences in the auditorium. It’s a natural progression.

“We wanted the students to learn how to pitch in a small place, one on one; in a medium space, with several people; and in a large auditorium in front of 200 people; as well as being able to learn how to pitch electronically to investors,” says Vann.

Training includes one-on-one guidance; high-impact seminars, workshops, and courses; resource tools, information, and funding; and a connection to the university’s larger entrepreneurship community. The program’s success has been noted by Pitchbook, a private equity tracker, which ranks Duke 20th among U.S. universities in producing startup founders.

But before students can pitch a product, they must have a product to sell.

Back on the main level, they go to work in design-focused garage labs, so called because the rooms include garage doors that provide access to the patios outside and make it easier to move large prototypes. Students can work indoors or outdoors on projects, which can be displayed outside.

As might be expected, the garage labs offer plenty of storage space, allowing students to secure their work out of the way of the next class in bays that are reconfigurable to accommodate projects of different sizes. Adjacent to the garage labs are a design lab and finishing studio with a stand-up paint booth, grinders, sanders, and other finishing tools, including supplies, equipment, and support to help students complete and fine-tune their creations.

Graduates of programs accredited by the Engineering Accreditation Commission of the Accreditation Board for Engineering and Technology (ABET) are required to have completed capstone design projects. But, like famed Coach Mike Krzyzewski’s freshman basketball recruits, these Blue Devils are expected to contribute immediately. In the First-Year Design course, each fledgling engineering student addresses a community client’s “problem or situation or something they are needing to solve. And as a result, they get to really make something,” says Vann. “They do it their first semester, right out of the gate.”

Undergrad engineering students account for about 1,200 of Duke’s total undergraduate enrollment of 6,500, a figure expected to hold steady. However, the school’s ranks of graduate students (nearly 1,300) and faculty members (155) have grown significantly in recent years. To that end, the construction includes 30 new faculty research lab modules and more than 170 graduate student and research write-up, lab manager, and post-doctorate work stations.

In the Neighborhoods

The top three levels of the building are home to the research neighborhoods: environmental health, health innovation, and computing and artificial intelligence. Each is designed to bring together researchers from across departments and disciplines who are focused on common goals, with wide hallways that encourage serendipitous interactions.

The infrastructure is laid out from the center of the building, supplying process-chilled water, RO/DI water, vacuum, compressed air and gases, emergency power, and other services. One specific need, especially for faculty in the environmental health group, is high-purity nitrogen for mass spectrometers. “So, we went ahead and invested in high-purity nitrogen available throughout the building, with stainless steel piping and risers,” says Vann.

Allowing for “research on display,” visitors have small views of faculty research lab interiors from the collaboration corridors, but most of the walls are a corkboard surface to install research posters and information.

“Posters are a great way for faculty and students to share their work, to have students come upstairs to read about what’s happening in the lab, what research is going on,” says Vann. “The walls also provide a great way to display art.”

In fact, the building was planned from the beginning to showcase a collection of artwork from students, faculty and community artists. Vann extols the importance of art in engineering, calling it “a great way for students to be creative in their engineering endeavors. It’s not just that you design something that’s static or only useful; it can also be very beautiful and inspirational. And that can really move people.”

Another unusual feature of the neighborhoods involves the grad student stations. Students are lined up against the windows, bathed in natural light. To make certain the laboratory gets natural light, the window shades power up, not down, on the south-facing side of the building. This allows the light to stream in over the workstations like high transoms.

Saving Energy

The university expects to not only meet LEED standards but to exceed them. The university is seeking LEED Gold certification and focusing on several items to increase the building’s sustainability, functionality, and flexibility, including chilled beams and an HVAC system designed to make it possible to change dry research lab spaces into wet research lab spaces fairly inexpensively:

- Plans call for employing Maxi-Therm™ steam-to-water heat exchanger technology.

- One of the key energy savings measures is the utilization of active and passive chilled beams for cooling offices and lab spaces. The chilled beams require only about 30 percent of the airflow that would normally be used to cool the spaces in a building of this type. To accommodate for the reduced airflow, the rest of the cooling load is met by routing chilled water, which is a more energy-dense medium, to the chilled beams to further cool the air. It takes less energy to pump water to the chilled beams than it takes to move large quantities of airflow, resulting in reduced energy usage.

- Because this is a laboratory building, all of the airflow that is used for cooling and heating is then exhausted to the outside and not recirculated. An energy recovery loop routes water from a heat exchanger in the exhaust air stream to a heat exchanger in the supply air stream in order to recover heat from the exhaust during the winter time and to channel excess heat to the exhaust during the summer time. This reduces the demand on the university-provided chilled water and steam utilities.

- An environmental monitoring system was installed that continuously monitors volatile organic compound (VOC) levels in laboratory spaces and carbon dioxide (CO2) levels in densely occupied spaces. This continuous monitoring is used to make sure spaces in the building are not “over ventilating,” meaning that the airflows are reduced as much as is safely reasonable to save energy. In the event that high VOC or CO2 levels are detected by the monitoring system, the airflows increase temporarily to purge the spaces of excess VOCs or CO2.

- During the design of the building, wind tunnel testing was performed on a scale model of the campus to determine how impactful the laboratory exhaust would be on the surrounding buildings. The purpose of the wind tunnel testing was to determine the velocity at which the exhaust needed to discharge from the building in order to prevent the exhaust from being re-entrained into other buildings’ air handling systems. The resultant velocity from the wind tunnel testing was lower than originally anticipated and allows the exhaust fans to operate at a lower speed, saving energy.

“Sustainability is important to our students,” says Vann. “They expect it from us, particularly engineering students.”

By Bob Stein

| Organization | Project Role |

|---|---|

|

Bohlin Cywinski Jackson

|

Architects

|

|

Skanska USA

|

Construction Manager

|

|

Stewart

|

Civil and Structural Engineer

|

|

Affiliated Engineers, Inc. (AEI)

|

MEP Engineer

|

|

Surface 678, PA

|

Landscape Architect

|