Animal care technicians are often the unsung heroes of vivaria and animal-related research, and they’re increasingly hard to find. Many workers find the low pay and repetitive work unappealing, and most laboratories find it hard to attract and retain animal technicians. Emerging research is testing whether automation of low-level tasks can help fill the gap while maintaining or even improving the animals’ quality of life.

“People are expensive,” explains Jeffrey Zynda, principal and regional science practice leader at Perkins&Will in Boston. “We design so much around the human component of animal facilities when, really, we can be much more targeted and focused towards the animal needs.”

Reducing Throughput

For facilities that aren’t ready to go the full robot route, data gathering and analysis can help lab managers and designers focus on the work that is most helpful for both animal well-being and quality research results.

Zynda describes a study at a major New York City institution that investigated the need for cage washing in a population of 8,000 lab mice. Standard approaches called for washing all 8,000 cages every week, which would have required 1,200 sf just for cage-wash operations. At New York construction prices, even several years ago, that would have cost $1.7 million to build.

So it was critical to determine how much cage washing was actually necessary: They did a case study with 480 cages, using sensors and monitoring technology to demonstrate that washing only the cages that met a standard definition of “soiled” could cut costs for that operation by about $500,000.

A subsequent study looked at a slightly larger population (600 cages) and found that just by reducing throughput, they were able to take the cagewash operation from 13 FTEs (work hours equivalent to a single full-time job) to five. That freed up the other workers to take on higher-order work without sacrificing cage cleanliness. “So, overall, 12 people were able to be retasked toward animal health and welfare monitoring, eight on the wash operations and four in material handling,” says Zynda. “Overall, there was a big range; the retasking of people saved quite a bit of money in this particular situation.”

Similar studies can help vivaria optimize the amount of money and energy spent on air changes, an expensive part of operating an animal facility. “Continuous monitoring allows you to reduce those air changes from 15 to 20 at the upper end down to four to six air changes per hour,” says Zynda. “Or, in other terms, a 60 to 75 percent air-side savings by using some of this digital technology.”

Animal Wellbeing

John Hasenau—a veterinarian and the principal of Lab Animal Consultants and an expert in lab animal medicine as well as facilities designed for lab animals—is an advocate for automating as much routine lab animal care as possible, not just because it can save money, but because it can lead to less stressful lives for the animals.

“We’ve seen that there is some stress from being around people,” says Hasenau. While being around animals can be beneficial to people, the opposite is not always true, and that can have an unwanted effect on research results. “By decreasing the housing changes or at least documenting them as part of the study, there’s less variation. Having fewer people in the room and less handling of the animals decreases that activity variation. That leads to less disruption of the animal and less data disruption.”

Hasenau and Zynda are testing a combination approach that includes robotic automation of repetitive tasks—similar to innovations currently in use in the pharma industry—and sensors and cameras to monitor animals non-intrusively. Automated guided vehicles (AGVs) can move cages from one place to another, and since they can operate in the dark, the facility can recoup some of the energy costs needed for the vehicles.

A Russian Resolution

While many of these technologies are still in the testing phase, Zynda points to Technopark Skolkovo, outside Moscow, where labor costs are also a factor for vivarium managers. The 65,000-sf facility houses about 12,000 rodent cages, about 100 primate cages, and 30 canine pens. Original plans called for 12 FTEs working to continually wash and sterilize animal habitats. Zynda recommended changing to a batch process, which allowed the facility to reduce cagewash staff to nine and provided a more varied workday for the humans.

After that, multi-axis arms were added to both the soiled and clean sides of the operation to help move cages from place to place, and then robots to further automate the washing process. “Ultimately, the solution here was to look at removing the serial process altogether, looking at complete batch processing with robotic enhancement,” says Zynda. “That reduced that FTE load down to five: somebody overseeing the operations, two load people, and two unload people in movement. And that produced nearly $242,000 in estimated savings annually.”

Moving Cages

In subsequent projects, Zynda and Hasenau have looked at the human workload in animal facilities to find further opportunities for automation. One such opportunity is the work of moving cages back and forth.

“When we look at an average animal facility of fewer than 10,000 cages, the percentage of time spent annually on movement to and from wash operations is about 20 to 25 percent of a technician’s time, or about 466 hours per year,” says Zynda. “When you start to add all that up, you’re essentially spending around $35,000 a year just moving cages.”

By deploying AGVs and the next-level technology—automated mobile robots (AMRs), which don’t have to follow a set path—cage movement doesn’t have to strain human backs. A robot costs money up front, but only a bit more than one year of a human worker, while it can keep working for years.

What’s Next?

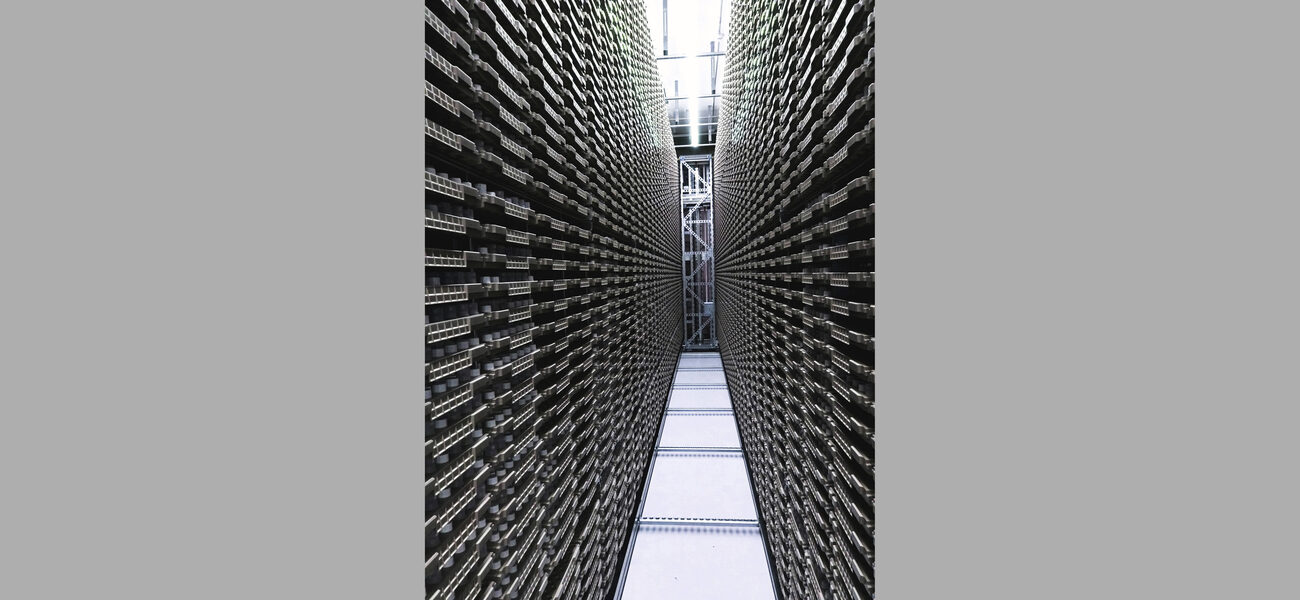

Hasenau and Zynda emphasize that any cost savings from automation should take a back seat to the goals of improving research results, animals’ quality of life, and humans’ jobs. Zynda explains that future animal facilities may be designed much less around the need for human bodies to interact with the animals. By deploying technologies currently used to store tissue samples—automated gantries for cage movement, for example—the same space can house about 56 percent more animals.

Hasenau also advocates research designs and adapted enclosures that allow studies to take place without removing the animal from its home cage. This reduces stress on the animal and makes it easier to avoid anomalies in data collection. By gathering more information—getting more data from fewer animals, as Hasenau describes it—scientists and lab managers can maximize their investment in live subjects while also providing a more stable environment for the animals.

One advantage of automated monitoring of animal cages is that, unlike humans, cameras and sensors don’t need to sleep. That means they can detect and record activity at night, when mice and rats are most likely to be active. “It augments welfare as well,” says Hasenau. “You can predict when you actually need to change the substrate.”

They point to an app called Betty, designed for farmers in New Zealand, where livestock are plentiful but field veterinarians are not. Betty uses the farmer’s smartphone camera to observe a sheep, then applies machine learning and facial expression recognition to help diagnose an individual animal. It’s not meant to replace a veterinarian’s care, but to help the farmer decide when to call in a professional.

“When we think about the potential of how that could be applied even further to take out some of the monitoring requirements and the health checks from a human labor perspective, this could be very easily applied in the next generation of animal facilities,” says Zynda.

Hasenau points out that while regulations often prevent today’s vivaria from experimenting with automation, things are changing, including the regulatory environment. Envisioning a world where technicians arrive at work in the morning with a full night of animal data ready to analyze, he says, “That is, I think, a better method than what we currently have.”

Where is all this leading? “I think you’re going to see an improvement in animal care and research outcomes,” says Zynda. “I wouldn’t be surprised to see cage checks driven by AI, putting together more complex patterns. That’s really the rocket ship that’s about to take off.”

By Patricia Washburn