Stanford University is committed to reducing carbon emissions across all scopes of work with the goal of achieving net zero emissions within its campus operations. To achieve this, the facilities department at the university is developing a database that tracks carbon intensities for different building types, updates facility design and project delivery guidelines, and implements whole building life cycle analysis for all major capital projects.

“Our facilities department has been working toward reducing embodied carbon emissions for quite some time,” says David Kirk, project executive for Stanford University. “Just in the last five years, this goal has gone from being something that wasn’t widely used or understood in the industry to something that is now being codified.”

In August 2023, the California Building Standards Commission passed two amendments to the California Green Building Standards Code, known as CALGreen, to reduce embodied carbon, making California the first state to address embodied carbon in a mandatory code. The new building codes, which take effect on July 1, 2024, will apply to non-residential buildings larger than 100,000 sf and schools larger than 50,000 sf. According to statistics published by the Carbon Leadership Forum, buildings account for almost 40 percent of global greenhouse gas emissions. Within buildings, operations make up 27 percent of the emissions, while building materials such as concrete and steel (also known as embodied carbon) make up 11 percent.

Defining Emissions by Scope 1, 2, and 3

Kirk explains that the first step in understanding the amount of greenhouse gas (GHG) emissions within your organization is to group the emissions into three categories known as Scope 1, 2, and 3. The term first appeared in the Green House Gas Protocol of 2001 and has since become a universally recognized method of defining emissions.

- Scope 1 emissions are direct GHG emissions that occur from sources controlled or owned by an organization. Stanford defines Scope 1 emissions as emissions from its campus fleet and the natural gas used to heat buildings.

- Scope 2 emissions are indirect GHG emissions associated with the purchase of electricity, steam, heat, or cooling. At Stanford, purchased electricity accounts for all of the university’s Scope 2 emissions.

- Scope 3 emissions are a diverse category of products and services that aren’t controlled directly by the organization, but the organization benefits from these emissions. At Stanford, student travel is a Scope 3 example. Stanford doesn’t cause those emissions, but students coming to campus emit these emissions on behalf of the school. Other Scope 3 emissions examples at Stanford include employee commuting, campus leasing, and other purchased goods and services.

“Over the last decade, we’ve taken major steps to reduce Scope 1 and 2 emissions,” says Kirk. “We now can show that emissions caused by construction activities are actually higher than the energy needed to run the building.” The result is that the majority of carbon emissions of new facilities built at Stanford are greater on day one of operations than for the rest of the life cycle of that building.

Whole Building Life Cycle Assessment

Stanford measures the embodied carbon in its buildings using the Whole Building Life Cycle Assessment (WBLCA) method which analyzes every aspect of the facility from material selection and delivery methods to final construction. “If you are building a new facility, the cost to do a whole building analysis is marginal, but the potential long-term impact can be very significant,” says Kirk. “A wide variety of software tools are now available to streamline the process and make the required level of analysis very feasible.”

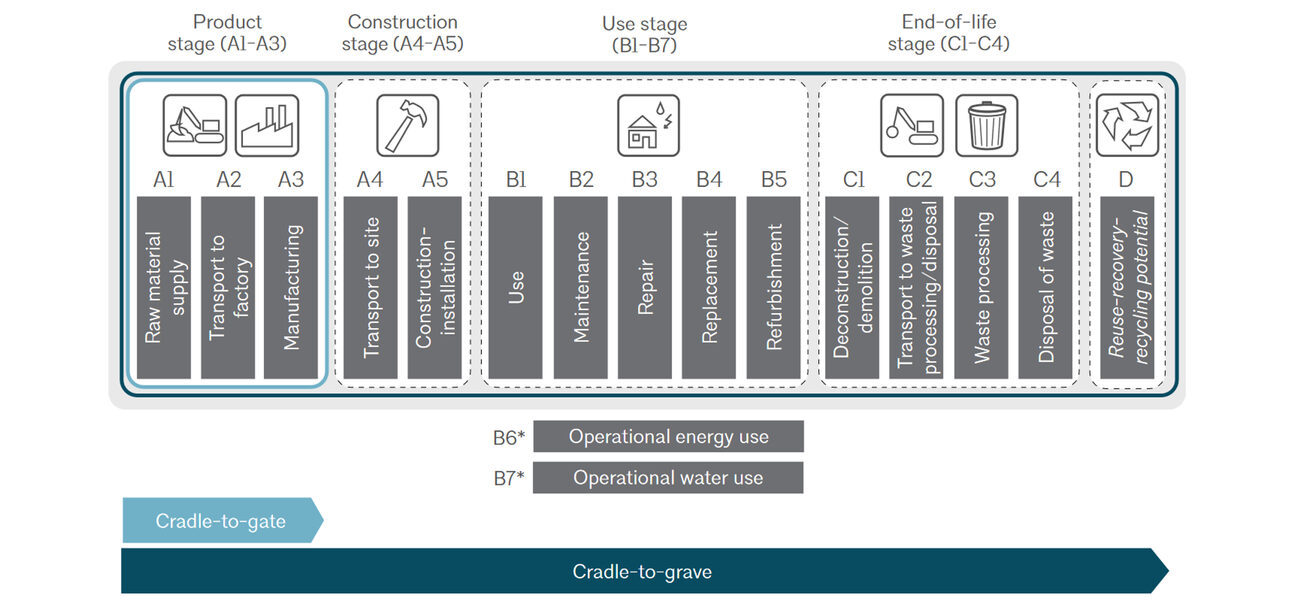

The WBLCA starts by reviewing the product stage—what raw materials are being used and how these products are transported to the site. The construction stage analyzes how the products are assembled into the facility. The use stage details everything from ongoing maintenance—such as filter replacements, life expectancy of HVAC equipment and roofing materials—to the expected end-of-life stage that includes demolition, debris removal, and potential recycling of waste.

“We look at all of these stages holistically to help us understand how much embodied carbon is in the building,” says Kirk. “To really make significant reductions in carbon and greenhouse gas emissions, changes need to be made in the product selection and construction stages.” He explains that while Stanford does not use a specific formula for analyzing the carbon cost of ordering and shipping a low-carbon material compared to a high-carbon product produced locally, Stanford has found that carbon emissions from transportation are minimal compared to product manufacturing.

Carbon Intensity Database

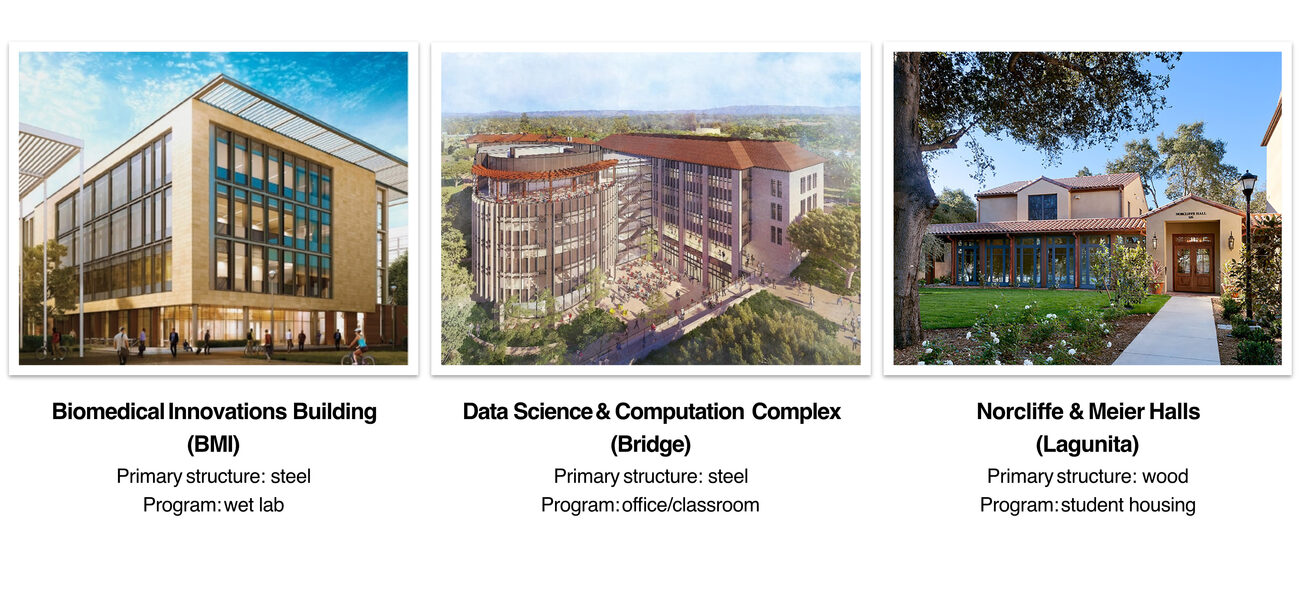

To help with product selection and design efficiency, Stanford is developing a database detailing the carbon intensity for standard facility types with the goal of better understanding how those emissions can be reduced. Stanford intends to collect enough data to more accurately predict how much embodied carbon per square foot should exist within office buildings, labs or student housing buildings. The database will analyze high-impact materials such as carpet, steel, concrete, and drywall, and will eventually include a baseline of all building types included on campus. The first three facilities analyzed were:

- The Biomedical Innovations Building, a steel-framed wet lab facility

- The Bridge Complex for the Digital Future, a steel-framed academic building housing data science and computation labs, classrooms and offices

- Norcliffe and Meier halls, also known as Lagunita, a wood-framed dormitory

Stanford’s analysis showed that structural systems have the most significant impact on the overall carbon in the building. This initial study indicates that as much as 84 percent of emissions occur at the product stage, meaning that embodied carbon in the materials account for most of Stanford’s facility emissions. In contrast, emissions during the construction stage, such as from heavy machinery used on the jobsite, comprise only three to five percent of the total emissions in the building’s life cycle.

“The consultants we worked with did not originally include emissions from MEP systems or landscaping in the analysis until we told them to include everything,” says Kirk. “That was a big ‘aha’ moment to realize that many organizations that claim to be net zero may not be factoring everything into their equation.”

The study also highlighted the importance of material optimization. The wood-framed building has roughly 50% less embodied carbon per square foot than the steel-framed buildings. If one takes “credit” for the biogenic carbon stored in the lumber, wood framing is roughly 20% less carbon intensive than steel. While the outlook for wood framing and mass timber is promising, there are important tradeoffs that warrant further study, such as seismic performance, longevity, and vibration criteria (particularly in high-performance research facilities).

Stanford is revising its facilities design guidelines to encourage use of lower-carbon materials. “There are more and more options available now, including low-carbon steel, concrete mix designs, and carpet,” says Kirk. He adds that carpet is a very high-embodied-carbon product and gets replaced quite often, especially in student housing.”

“Stanford prefers not to use carbon offsets,” says Kirk, who feels that the practice often amounts to greenwashing, a term used to describe statements that claim products or policies are more environmentally friendly than they really are. “A lot of companies will claim that their products are low carbon, or even net zero because they have procured carbon offsets to mitigate the negative impacts of manufacturing their product and delivering it to market,” says Kirk. “To me that is disingenuous. It’s similar to putting solar panels on top of a 20,000-sf mansion and saying that makes the home ecofriendly.”

Stanford’s current goal is to reduce embodied carbon by 20 percent on all major projects; its long-term goal is to establish embodied carbon goals based on carbon intensity benchmarks rather than a percentage reduction from the baseline, explains Kirk. “Moving toward a carbon-intensity model is a more rigorous approach and will give us more of an absolute certainty in terms of the impact of our facility design,” he says.

By Amy Cammell