Advanced manufacturing (AM) experts say companies around the country that are currently trying to build up their AM capabilities are held back by three things: experience with cutting-edge AM equipment, experts who can show how to take full advantage of such equipment’s capabilities, and highly trained workers who have the skills to operate the equipment. Administrators at the Missouri University of Science and Technology in Rolla hope to fill all three gaps with the help of a new facility they call The Missouri Protoplex.

Unlike a traditional university research laboratory, the Missouri Protoplex will be focused less on basic research than on helping companies become familiar with a variety of new AM technologies, giving them access to faculty expertise, and building a pool of skilled labor capable of operating the complex and powerful AM machines.

The Protoplex program is perhaps more analogous to a different American research tradition—the agricultural extension service, through which land grant colleges like Missouri S&T introduced American farmers to the latest agricultural techniques and technologies, accelerating the transfer of agricultural knowledge.

The challenge this time around is similar, in that AM is very different from old-line manufacturing. “Rather than focusing on internal fundamental work, it’s very focused on prototyping, processes, development, and close collaborations with companies,” says Richard Billo, professor of mechanical and aerospace engineering at Missouri S&T, founding director of the Kummer Institute Center for Advanced Manufacturing, and director of the Missouri Protoplex.

Brave New Shopfloor

AM involves the use of advanced technologies—including robotics, automation, 3D printing, artificial intelligence, and the Internet of Things—to streamline production processes, reduce costs, and improve product quality. It incorporates such advanced systems as computer numerical control devices capable of six-axis production—an arm that combines three linear axes with three rotational axes, making it possible to produce intricate shapes and contours without repositioning the item being made. In addition to creating greater efficiency and the ability to produce one-off parts, some AM systems are capable of remanufacturing: repairing and restoring old parts to like-new or even better-than-new condition. Protoplex will offer a variety of technologies, including:

- Cold spray additive manufacturing, which shoots metal powder at supersonic speeds that bonds on impact with a metal plate, forming layers that create a 3D part.

- Friction stir additive manufacturing, which involves pressing a metal rod against a plate at high speed to generate heat, melting the rod and building up layers in a way that is sometimes superior to parts forged using traditional methods.

- Wire arc directed energy deposition, which welds layers of metal wire onto a substrate that can be used to produce parts up to 8 feet long.

“These are all digital technologies, typically. You do the engineering work, the program is generated, you push a button, and your parts get made,” explains Billo.

But it takes much more than a free index finger to succeed with AM. Companies need the support of domain experts as well as workers trained in disciplines as varied as robotics and 3D printing, metallurgy, nanotechnology, chemistry, and biology, according to Billo. They also need instruction in the use of new kinds of materials, such as carbon-carbon, a substance that didn’t exist until just a few years ago, but that is now being used in hypersonic vehicles.

In addition to guidance and support, Protoplex offers major industry partners (such as Boeing, Caterpillar, and Sikorsky) and smaller businesses a low-risk way to access and test-drive new equipment. “Rather than listening to a salesman try to sell them an $800,000 machine, they can come in and rent our machines for $100-125 an hour, develop their products and processes, and see if it makes a difference,” says Billo.

The partner company also gains an opportunity to use the equipment without disrupting its current production line—a key consideration for any company before it orders a massive piece of equipment like Protoplex’s friction stir machine, a 14-by-14-foot behemoth that weighs about 25,000 pounds.

Other opportunities may arise as well, as corporate partners are often invited to apply for federal research grants with the university.

The Missouri S&T facility is part of a larger effort underway in Missouri and all over the U.S. to rebuild manufacturing capacity, after decades in which trade policy encouraged the growth of supposedly higher-value services and discouraged manufacturing.

The state’s program, the Missouri Protoplex Initiative, includes not only S&T’s building but facilities at St. Louis Community College, St. Charles Community College, East Central College, and Ozarks Technical Community College.

But three or four decades is a long time, particularly in technology, and Missouri S&T leaders also sought outside expertise to build a model facility that would show companies how manufacturing can be done today.

For guidance about what such a facility should look like, Missouri S&T turned to the science and technology practice of Perkins&Will, which had designed somewhat similar facilities: the Commonwealth Center for Advanced Manufacturing (CCAM) in Disputanta, Va., as well as the Robert Plaster Center for Advanced Manufacturing at the Ozarks Technical Community College in Springfield, Mo.

The S&T team also looked toward the United Kingdom, where 85 similar facilities were built two decades ago as part of a nonprofit consortium called the Catapult Network, which has proven itself to be a valuable part of the U.K.’s own emerging AM ecosystem.

Protoplex, Defined

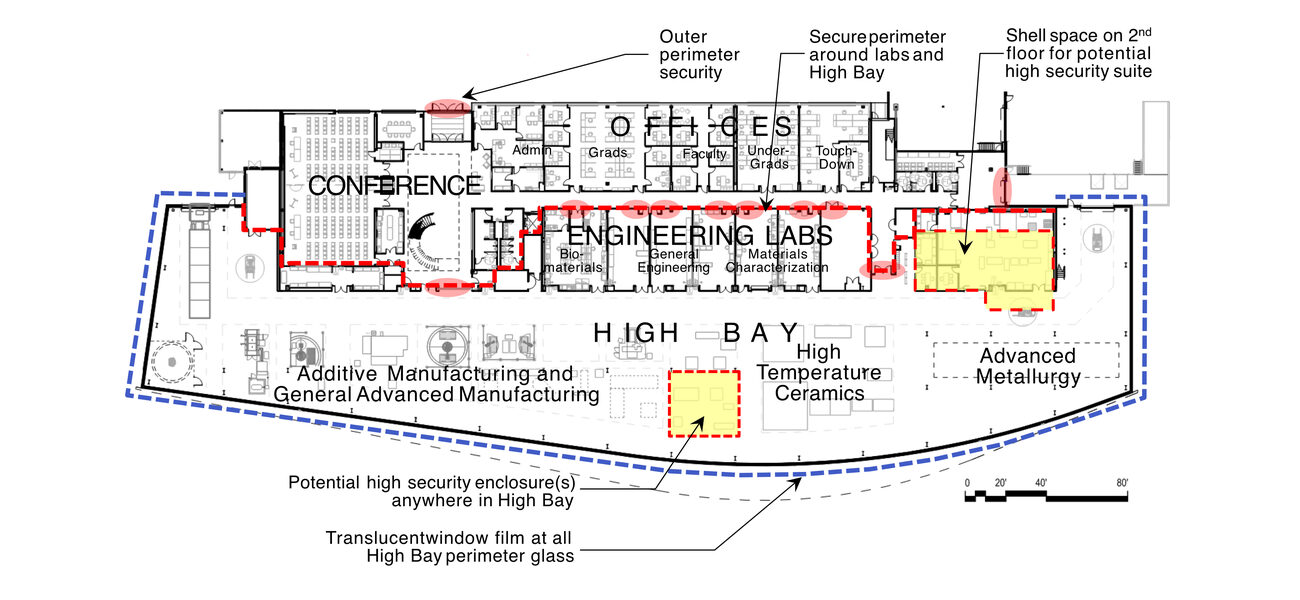

Space in the $66 million, 117,000-sf building will be divided between a 24-foot-clearance high bay and two stories of laboratories, meeting rooms, and offices, most of which are designed to be easily reconfigured as needs change.

Each of the 20 separate equipment cells will be able to support 50 watts of electricity per sf. The high temperature ceramics area can support 100 watts, while advanced metallurgy can support 150 watts, “because that foundry equipment consumes electricity like you wouldn’t believe,” says Paul Harney, a principal in the science and technology practice of Perkins&Will. Fume hoods may also be installed where needed.

The floor of the building rests on a 10-inch-thick slab of reinforced concrete. The HVAC in the high bay, which includes metallurgy and ceramics, will be capable of handling 6 air changes per hour, but will normally run at about 2 ACH, according to the designers.

There will also be a traveling bridge crane, which will be limited to one end of the building. “We debated this topic up and down and sideways, and decided to only put the crane where it mattered the most, which is over the very large and heavy foundry equipment in the advanced metallurgy area, because otherwise cranes can get in the way of being able to drop services directly from the ceiling down to equipment below,” explains Harney.

Frosted glass instead of clear picture windows was another compromise. Because many of facility’s activities will involve confidential industry projects or Department of Defense contracts, the team needed to be careful about what could be seen from outside the building, explains Billo.

With outsiders in mind, another requirement is a viewing gallery that will enable the 12,000 K-12 students and other visitors Billo expects will tour Protoplex annually, to walk through the facility and see the variety of projects being undertaken without having to badge in past a security checkpoint or put on safety gear.

The building is under construction, with move-in scheduled for spring 2026. Currently, Protoplex activities are taking place in 10,000 sf of high bay spaces across two buildings. Around 250 students—a number he expects will double next year—will take at least one of the seven courses that will be taught in the building, including courses in additive manufacturing processes and controls applications.

Lessons Learned

The design team also learned from mistakes made in previous AM facilities. At an AM facility in Sheffield, U.K., administrators told the Perkins&Will architects that they regretted not having enough room to accommodate large conferences of 150-200 people. At CCAM, the administrators had regretted not including a full-height loading dock. Both features were included in Protoplex.

To determine which machines to buy, Billo asked industry partners rather than faculty. This helps the companies and, indirectly, helps S&T students as well, as it ensures they will graduate knowing how to operate the same equipment they will find at the companies where they hope to work.

Finally, future flexibility was a key consideration. “The building should not get in the way of change,” says Harney. “We really tried to think ahead…hopefully, we’ve provided a building that will work on day one and that will also work on day 10,000.”

By Bennett Voyles