The following is a condensed transcript of a panel discussion from Tradeline’s 2013 International Conference on Research Facilities. The panelists are William Gustafson, principal at Ballinger; Steven Frei, principal at Affiliated Engineers, and Michael Reagan, vice president of Stantec. The moderator is Steve Westfall, founder and CEO of Tradeline.

Westfall: What do you see currently going on with respect to research facilities capital projects, and what sort of planning is in the works?

Gustafson: We are seeing an environment where money for capital projects is much tighter than it has been in recent years. 2010 was a watershed year in that regard, once the bubble burst on the general economy. Projects now require much more analysis up front to be justified. There was a time when you got money at the beginning of a project, and you just proceeded through. Now it is a question of stage-by-stage approvals. We are working in a cautionary environment, even for projects that ultimately will be built.

Westfall: In terms of the sizes of projects that you are seeing, have large projects disappeared from the landscape or simply gotten smaller?

Gustafson: The mega-projects are not as prevalent as they were, reflecting, again, the tighter economy. On the other hand, research is regarded as a fundamental aspect of both the business climate and university climate, so ultimately these projects get done. They may just take a more circuitous path.

Frei: I agree. We see a mixed perspective on what is coming in the door today. Work for the federal government clearly has become less today than what it was a couple of years ago. States are very mixed: some are spending a great deal of money, which is surprising. Others are doing quite a bit less. As for the scale of projects, some of the private academic institutions seem to be building at the same rate, whereas public academic institutions are doing less.

Reagan: There seems to be fewer and fewer federal dollars, forcing institutions to think about partnerships with private industry. The National Research Council in Canada redirected the focus of research in Canada to a more applied science approach, looking for an end product. Basic research seems to be less prominent these days. We are seeing more engineering projects, which seems to suggest a more applied science approach. In the near future we are going to see a lot more public-private partnerships in this country, which is already prevalent in Canada.

Westfall: By “public-private partnerships,” are we talking about developer-built projects?

Reagan: That as well as industry partnership. Many universities are now partnering with industry to collaborate on research programs, and allocating space for industry in their buildings so they can begin developing products together.

Gustafson: One example of university-industry partnership is the broad and very fruitful phenomenon of linking engineering and science in pursuit of producing tangible scientific products. I know several universities that recognize that their medical and engineering schools need to match up. Given the evolution that has come out of the genome project, there is unlimited potential. It is a matter of getting engineers to collaborate with subspecialists in medicine, and I am seeing some universities that are embracing that fully. That is a sea change in terms of their mindset from the past, where engineering was here and medicine was over here. That is the future.

Westfall: Let’s talk about high-value features for research facilities and investment tradeoffs that are being made to get those features. What features do research organizations most want, and what sacrifices or tradeoffs are they willing to make to get those features?

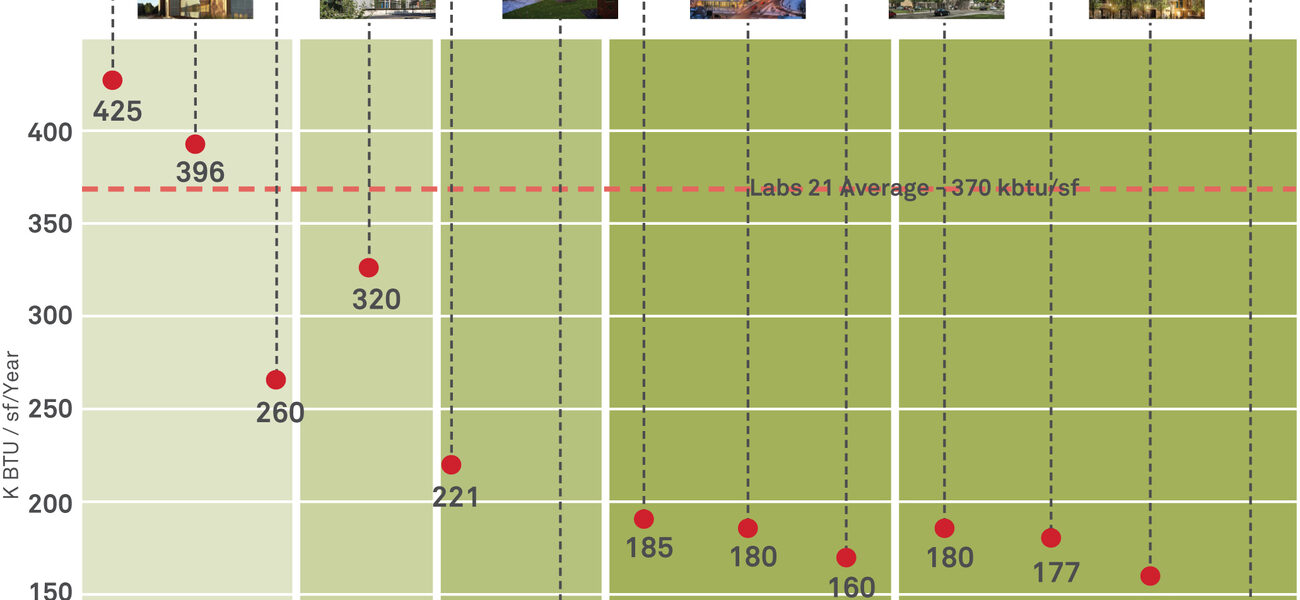

Frei: Sustainability is very important to the vast majority of projects today. That is in part driven by the owner’s desires as well as the code expectations, which are pushing us towards higher degrees of energy and water efficiency. As it relates to investment tradeoff, in most cases organizations are looking at not just the simple first cost and payback but also for lifecycle cost studies.

Audience comment: In Pennsylvania, we have seen a tremendous increase in natural gas production from shale, and the general forecast is for at least 10 years of inexpensive natural gas and the corresponding prospect of low-cost energy. How do you think this is going to affect the whole sustainability agenda?

Frei: It is going to have an impact on the financial analysis. The savings from otherwise attractive sustainability initiatives may not be there because the cost of gas is so low. One of the things we are seeing on the flip side of that is that while the cost of gas is low, water prices across the country are rising fast. Water and energy are being tied together in the evaluation of a growing number of sustainability decisions.

Audience comment: Some of the more sustainable systems—OptiNet from Aircuity—although they are expensive, they mean smaller main mechanical systems, chillers, and air handlers. A challenge in Canada is that the engineering teams, and even some of the architect teams, aren’t willing to embrace it. One argument is that it is more work for the engineering and architect teams to do it, because with lower construction costs, design fees are less. What incentives do we offer to the engineering and architectural community to push the sustainability?

Frei: That is a valid point: The willingness to accept new technologies. The Aircuity system typically takes more than one conversation with an owner and EH&S group to gain comfort with it. We are finding that less than half of our sustainability effort is in financial analysis and more than half of the time is spent informing the stakeholders. As a firm we try and break that out of the basic services piece and just identify it as something above and beyond what we would normally have to do.

Gustafson: It took awhile for the word “sustainability” to catch on, and now virtually every project brief we receive has some language in there about sustainability. On the design side, the learning curve was very fast. People quickly realized things could be done that would make a real impact. But when are we going to see targets set for sustainability by owners saying, ‘This is what we think you ought to shoot for, because ultimately we have to pay the operating cost of the building’? That tension between the design and the systems is a healthy one. The earlier it is brought to the table, the better.

Reagan: Many state projects have sustainability mandates. Silver is the minimum. Many are willing to spend the extra money for the certification. I am curious to hear: What does this group feel about getting that LEED certification piece of paper, or is it just enough to design to that level? There is a lot of paperwork involved in getting the certification and the plaque on the wall. Actually, there is a fee associated with that, and a lot of the owners we are working with don’t want to pay that.

Audience comment: The University of New Mexico has a 30-year carbon neutral plan, so not only do we set the standard above what the state mandates for our funding, but we set it in a global way for our campus. Buildings, depending on when we are constructing them, have different energy-saving targets. This leads to my question: Often our architects will look at sustainability only within the building envelope. We have asked them to look beyond it for our entire campus plan. Particularly urgent for us now is water conservation. We not only are finding it difficult to find architects willing to do that, but how would they build it into their fees?

Frei: We have been involved in a number of projects where we are asked to look at the campus as a whole. Some of the climate action plans that we did several years ago had to look at the energy and at the water usage. That was a great learning experience to force everyone to look outside the box and not just look at the one building project.

Audience comment: What do you see on the academic institutional or private side as being an acceptable return on investment for sustainability initiatives? And what do people most often put on the table as something to add to the project as part of a long-term payback analysis?

Frei: There are many different technologies for which ROI for sustainability comes into play, for example chilled beams, reducing air quantities, and fume hoods controls. The ROI approach is not commonly done on academic campuses. While these institutions do not look at ROI, an increasing number of institutions are looking at these options from a lifecycle cost analysis point of view.

Reagan: Heat recovery is pretty much at the top of the list. In terms of payback, 10 years is pushing it; a five-year payback would be nice. We worked on a project at Cornell where the heat recovery payback was longer than 10 years, but because we were saving so much on everything else, they chose to pay the premium for that.

Gustafson: I don’t see a lot of consensus on what a legitimate payback period should be. I think we are drawn to the longer-term view of buildings, that these buildings are going to last 50 years or more, but many times the client perspective is much shorter, and five years is considered an awfully long payback. I think the point here is not to get too focused on single-item sustainability investments, but take the larger view as noted by the University of New Mexico comment.

Westfall: Is there nothing else on the list of high-value features that people want? Is it just sustainability?

Gustafson: One of the things that has changed markedly is the recruiting environment. You might say, ‘How do you design for someone who is not there?’ It has been a good thing because it ties in to flexibility long term.

Audience comment: With respect to operating costs, can you speak to the implications of high-performance equipment and controls and how that affects operations, maintenance, and staff training?

Frei: Our experience recently with a number of projects involving high-performance equipment and controls, is that the design and the construction appear adequate, but the commissioning process has been insufficient to get these buildings truly up and running. It is taking longer to train individuals who are going to operate the building in the long term. Often due to budgetary limitation, there are fewer people with the capacity and the capabilities to take over some of these very complex systems.

Audience comment: I’m from Binghamton University. When you talk about sustainability and recruiting, we don’t look at just the researchers. We also look at students. For students of the future, sustainability is what they are going to have to do, so we are using our buildings as a teaching tool. We might pay more money in capital expense to put something in. Maybe there’s not a clear-cut financial payback there, but a number to get that better researcher or those more in-tune students.

Reagan: We have seen in some cases that sustainability is almost a requirement to get students. I can’t put a price on it, but we agree that there is a value to that in retention and attraction of students and faculty.

Westfall: How do you convince an existing institution that 10 years from now, the people who will be doing research there are now in high school and are being trained to work differently than today’s research environment is designed for?

Gustafson: I think that is a fundamental issue because, oftentimes, on the client side it is the senior faculty that we have interacted with, not the junior faculty, let alone incoming students. That is one of our challenges: How do we deal with that generation X, generation Y, and how different their attitudes are about everything?

Reagan: One trend we see is more and more student-involved research going on in liberal arts colleges. Research institutions that are looking to hire these students say that this kind of hands-on experience is what they want. And young students agree that they want hands-on experience from their first year, not just theory.

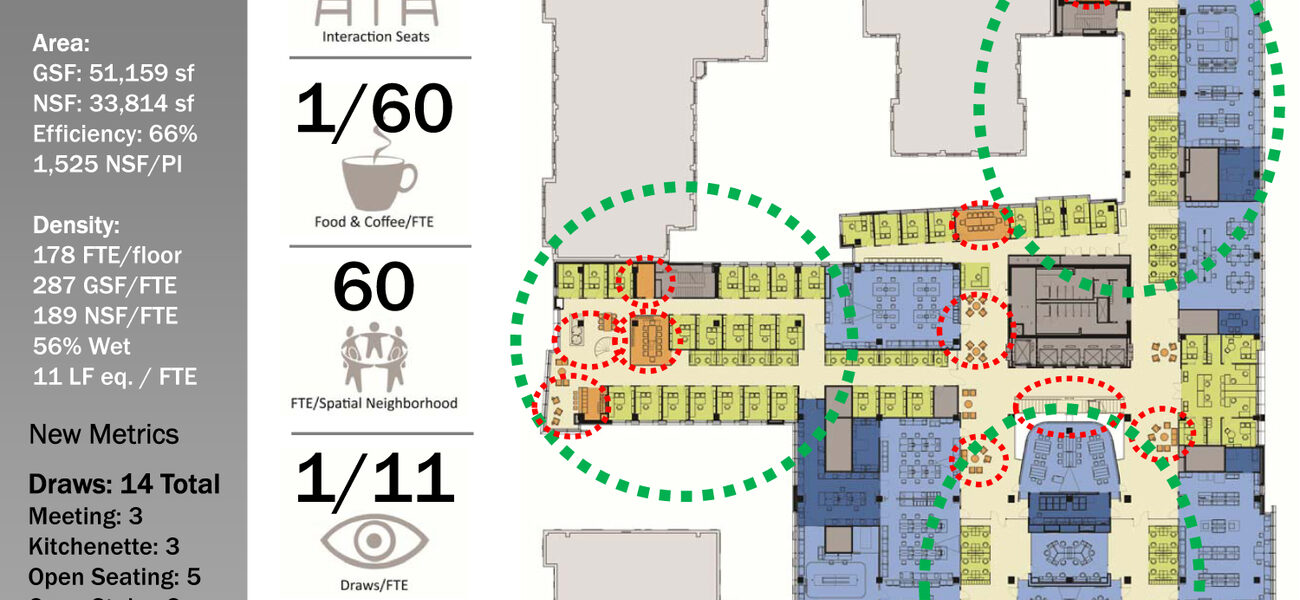

Audience comment: There seems to be a lot of concern about how we can enable our clients to get better research productivity out of the environments that we design for them. Are you seeing that? Are planning strategies actually targeting research productivity in some tangible way as a high-value project outcome?

Gustafson: I did an in-depth study of payback relative to research. Particularly in the biomedical world, some schools have looked carefully at what standard of return to expect from the researcher if we give them “X” amount of space, a square-foot-per-person standard. Eventually they got to the point where a standard of return on space constrains the purpose of the researcher, which is collaboration. The reason is because researcher “A” was worried about his space, his personal research revenues, and the prospect of losing his space. I don’t think productivity measures per square foot are the answer to the problem. At the same time, I think there is a legitimate concern about how research is going to continue to perpetuate itself in an increasingly competitive environment.

Westfall: Where are you seeing leading-edge examples of multidisciplinary collaborative research, and does this involve special facility features?

Gustafson: A recent project involved taking a whole range of disciplines—engineering, science, and biomedical—and saying, ‘Let’s put them all in the same building and explore the potential collaboration across that broad spectrum.’ This was immensely challenging to the faculty. If you don’t feel the space is owned but it is shared, that is a very different starting point. That is where the world is going.

Westfall: What are you seeing when people talk about doing a project that is going to encourage collaboration? Just coffee bars and cafés?

Reagan: We are still seeing coffee bars and cafés as an important part of the equation.

Gustafson: People are realizing that core facilities are a very important aspect of research collaboration. People interact around them because that is where you learn that other researchers are using that same core, and it creates a certain discussion. You also have to interact with the technical people running that core. It breeds a dialogue about what research people are doing. This becomes natural affinity-based research as opposed to the more casual interaction or encounters that are commonly thought of in this context. Imaging centers and cleanrooms are very expensive spaces, so institutions want to optimize the use of those types of facilities. There was a time when someone said, ‘I need this,’ and you tried to give it to them. But now the question is being asked, ‘Why not use the resource we have in another building?’ Or, ‘How is that going to work with other parts of the university?’ The day that core-type resources are controlled by a single entity is over. Shared resources are inspiring real collaborative science.

Audience comment: I believe you are correct that cores are incredibly important to research collaboration, but it is not so much the fact that you are bringing researchers together. The reality is that when researchers go into these core facilities, they are working in them, not talking to each other. The benefits that you get in collaboration are more around the ability to bring technologies into those cores that individual labs couldn’t afford. Rather than have one lab try to buy the latest two-photon confocal microscope, now you’ve got five or six different labs that put funding together, and they are going to be able to use that technology. On the other side, it is more than just having coffee bars. It is where you put that coffee and food. You have to put it strategically. A couple of people talked about it being immediately adjacent to entry points into a facility, which is where people stop or are going to be talking. You also need to have it where people are going to congregate naturally, where people have their meeting rooms and seminars. Our research teams told us the best collaboration is over food, but don’t give us a food court because that is the worst place ever.

Audience comment: Core facilities bring researchers together to use the same technologies and are better known as collaboration centers. Coffee means an interaction center.

Audience Comment: Collaboration has a specific definition in scientific fields, and that is ‘two or more people working on a specific idea or project.’ That’s the dictionary definition. So that would put interaction as meaning casual contact, which is different than collaboration.

Audience comment: We need then to distinguish between interaction and collaboration. Interaction may lead to collaboration. We are probably using the term ‘collaboration spaces’ too broadly. We are actually building casual interaction spaces with the hope that interaction leads to collaboration.

Audience comment: I think you get a lot of results from people finding a place to talk after work. We have designed in a place in Connecticut that is a pub for people to sit down and talk. In Bar Harbor, I have sat down with PIs and talked science. I am an engineer. But I have talked science with them over a couple of beers. We make a lot of ground right there. If you can create a relaxing environment in your facility that people want to stay at work and sit down for a casual hour or so, that is where you are going to gain. That is where the best ideas come from, after people relax and they can feel free to say whatever they want.

Audience comment: We see the benefits to the open office concept as a way to intensify space use and increase interaction and collaboration. But there is a pretty intensive pushback from senior faculty to move into open office and cubicle-type spaces. I’m wondering if anybody has successfully switched over from single-person researcher offices to an open-office type of research environment.

Gustafson: Certainly the trend is to more open office. The real question will be whether the faculty ultimately give up their private offices and join the rest. In any university, that is a real culture change, and it is not going to be done easily.

Reagan: I’ve seen it at a community college level and in industry. Some of the tricks are the size of the workstation or the open office, and also having enough white noise so that you can feel acoustically private at your space without having to hear 18 conversations, but still have visual connection with all your partners.

Westfall: Don’t you need some kind of a champion that has some power to make that happen?

Reagan: Absolutely.

Audience comment: Someone had asked a question earlier about how the younger researchers work together. You also had that chart showing the declining number of research papers per dollar spent. I suspect that is because communication is now taking place more electronically and less in traditional publications. We are talking here about these collaboration spaces, but more and more may be happening via handheld devices.

Westfall: So you are suggesting that more collaboration is happening, but in virtual space and not necessarily in physical space.

Audience comment: Not even at a desktop.

Westfall: Does anybody know about or have experience with some different metrics for measuring research productivity or studying research processes?

Audience comment: This idea of dollar spent per paper or per research square footage is an older metric that is not going into the next generation. It isn’t necessarily the right metric anymore.

Audience comment: The University of Michigan did a study on their new medical science research complex and looked at what additional papers or grants were awarded because of interdisciplinary collaboration, not at the fact that they put those groups in the same building on the same floor in the same module. They are measuring that as the end result of collaboration. The Beckman Institute at the University of Illinois is doing network analysis looking at the linkages between primary investigators and associate investigators working together that are named on joint programs and successful grants. They track not only grant applications, but the awards and the research being done. The premise is if those people weren’t together, they would not have collaborated on applying for that joint grant, much less been successful and been awarded the research, and then done the research collaboratively.

Audience comment: You can make the argument that the declining number of research papers per dollar spent is actually a measure of success of interdisciplinary collaboration, because you have more groups coming together on a single study rather than doing individual studies. Is that a loss of productivity, because now you have 20 groups on one paper?

Audience comment: Instead of looking at productivity in terms of collaboration, we’ve had clients talk to us about productivity on a process level inside a lab: Lean processes, spaghetti diagrams. It is a different attitude and a different way of looking at things, but it can save square footage and time, and show real results in terms of productivity at an assay or a process level.

Westfall: This is process analysis of the research activity? What institution do you know where that has been done or is being done?

Audience comment: Genzyme, Charles River Labs, and Biogen are a few that come to mind. To create the spaghetti diagrams, you have an observer in a lab watching a repeated process and drawing on a floorplan where people move from place to place to complete their process. It is remarkable. In interviews scientists will tell you that it takes them 20 or 25 paces and five minutes to complete something, while in reality it is taking them perhaps as much as 175 paces and 25 minutes. They don’t realize how far they move and how inconveniently things are located in the labs, especially on repetitive processes.

Westfall: Now I want to dive into a topic that is new to some people: Project delivery methods and how they are changing. Are people really doing integrated project delivery and Building Information Modeling, and if so how does that affect project teams, team formation, and how teams work?

Gustafson: For the last nine years I’ve done a study of the industry, interacting with CMs around the country. I thought integrated project delivery might have some traction, but it just hasn’t caught hold yet in our experience. Most of the examples are in California, and they are healthcare related. Steve Frei and I were involved in a project in Wisconsin that was full-bore integrated project delivery where we signed an integrated contract. We learned a lot from it, but in general it hasn’t caught on yet.

Reagan: I’d echo that, although I am working on a very large project in upstate New York for an industrial client who made the decision halfway through construction to go IPD. That is a very integrated team approach, and it has been reasonably successful. It takes a whole different mindset, though. It involves BIM and this whole idea of creating a digital model and then giving that model to the subcontractor to figure out how they are going to build it. It is supposed to reduce the number of shop drawings, which it has done to a certain extent, but that work has been replaced by multiple iterations of the model, where architects and contractors now have to figure stuff out together. So in terms of streamlining design effort, it has had limited success. The state of Ohio recently made IPD an allowable project delivery method, where for years it was not even considered. So we are starting to see some movement in the industry for different project delivery types.

Frei: I attended the Tradeline conference on Lean delivery, and it was surprising how many people were there from Boston, who talked about using IPD on projects. More of them are using the principles of bringing people in early, bringing the subcontractors in early, doing design assist for the MEP trades, but they are having difficulty actually getting to the multi-party agreement.

Gustafson: The term for that is ‘IPD-Light.’

Audience comment: Do you have any suggestions for what can be done to get IPD going a little more here on the east coast? I see that a lot of education up front needs to happen, at least getting everybody to understand the workings and what is required, but also the whole contractual side of it is always a big hurdle, especially for the risk management departments.

Gustafson: The barrier is that the subcontractors don’t have the skill sets to deal with the responsibilities that it requires. They don’t have the staff to manipulate the models, which is really what you need. That is where you need to attack. As architects, we are willing to work with other folks in the execution of a project, but you have to have a partner that has the same skill set. It is the contractors or the subcontractors that need to step up.

Audience comment: I’ve seen the project teams change over the years. Early on when I started in this business, commissioning wasn’t even part of the team, and now commissioning agents are coming to the table very early in the process. But a member of the team I see getting left out is the controls team. Are you seeing any trend of bringing controls in earlier in the process?

Frei: Relative to getting the controls contractor on board, most organizations across the country—pharmaceutical, institutional, or at the university level—do have their preferences for who their control contractor will be. Typically their control contractors tend to be campus wide; they are the contractors who have had contractual responsibility for more of an institution’s buildings than any other contractor. As an example, the project that Bill Gustafson and I worked on at the University of Wisconsin had the controls contractor as one of the design assist contractors that came on right at the end of the schematics, and the value of us to working together in doing the control sequences was tremendous in making for a much better product.

Audience comment: On a lot of campuses today, there is more consistency with the controls contractor than there is with the A&E or the design firm.

Audience comment: I think the controls contractor should be selected right up front and make input to the project early in the process.