In the ever-evolving quest for sustainability, engineers and their clients may find the 2013 updates to ASHRAE 90.1, the energy code that predominantly guides the design of buildings, useful in benchmarking energy efficiency for new or remodeled laboratories and vivaria. Regular review of the code ensures compliance for new projects and offers an opportunity to refine best practices for building envelopes, mechanical systems, lighting, and noise mitigation, say Adam Golubski and Philip Walter of The Clark Enersen Partners. With one new construction project and one renovation at a Midwestern university as examples, Golubski and Walter offer valuable lessons that can result in substantial savings.

ASHRAE 90.1, developed and regularly revised by the American Society of Heating, Refrigerating, and Air Conditioning Engineers, is the standard used by the International Building Council, as well as LEED, for points awarded to projects for energy and atmospheric sustainability. The 2007 standards were used as a baseline for Clark Enersen in their design of a new animal research facility and the renovation of a lower-level animal research facility. “Under the 2007 ASHRAE guidelines, we were almost 35 percent more energy efficient than the standards required,” says Golubski. “But if you look at the buildings’ designs against the 2013 standards, we barely meet the criteria.”

On the architectural side, ASHRAE 90.1 now mandates tougher requirements for roofs, walls, floors, and glazing. For mechanical engineering, some form of energy recovery is now a prerequisite, as is a variable air volume (VAV) system. Piping insulation requirements have been increased, as have guidelines for daylighting. Lastly and perhaps most importantly, HVAC commissioning—the thorough and comprehensive testing of these systems’ performance—is now mandated for facilities larger than 50,000 sf.

At a new LEED-certified facility that houses a wide variety of species, the 2007 guidelines were exceeded in part by the use of concrete block in a brick cavity wall, 2 inches of insulation, and low-emissivity glazing. “The university didn’t want to explore a total energy recovery wheel—they’d had problems in the past with urine byproducts getting into the airstream and destroying the wheels,” says Golubski. “This meant we needed to get creative to meet LEED requirements.” The solution was a runaround energy recovery loop paired with centralized demand-controlled ventilation to reduce air change rates in the holding areas. “It’s not as effective as a total energy recovery wheel, but it does carry a lower risk of cross-contamination,” says Golubski, adding that while the loop is also less expensive, comfort and understanding of the system is generally the determining factor. “The University wanted a low-maintenance system they were familiar with running,” he says.

ASHRAE 90.1 and the Whole Building

“Finding ways to beat the 2013 standards by more of a percentage is going to play a part in LEED certification,” says Walter. “That means looking at the whole building, including the envelope.” Calculating the return on investment for different wall insulation types, they determined that by adding insulation, they could achieve energy savings of about $1,300 per year; the energy savings will pay for the facility’s walls in 9.6 years. “Pushing the wall improvements further by adding 2 inches of poly foam and additional gypsum board would double the payback time,” says Walter. “So your break-even point is going to depend on your budget.”

For the building’s roof, heat island effect reduction was a factor. “Usually white EPDM is what you want, even if you have solar panels,” says Walter. “But in the Midwest, where we have some cold extremes in the winter, there are some benefits to having a dark membrane instead to retain heat.” The tradeoff may make sense in some geographic locations but not in others, he says. “I think in Phoenix, you’re still going to want white.”

The holding portions of animal research facilities often have few or no windows. However, with more stringent daylighting requirements in the 2013 guidelines, it makes sense to assess several different types of windows’ solar heat gains and shading. As with their analysis of the facility’s walls, Clark Enersen looked at satisfactory, good, better, and best alternatives in terms of ROI. Their findings? “If you have a small number of windows, it probably makes sense to upgrade them,” says Walter. “The simple payback was only about 2.3 years for this project.”

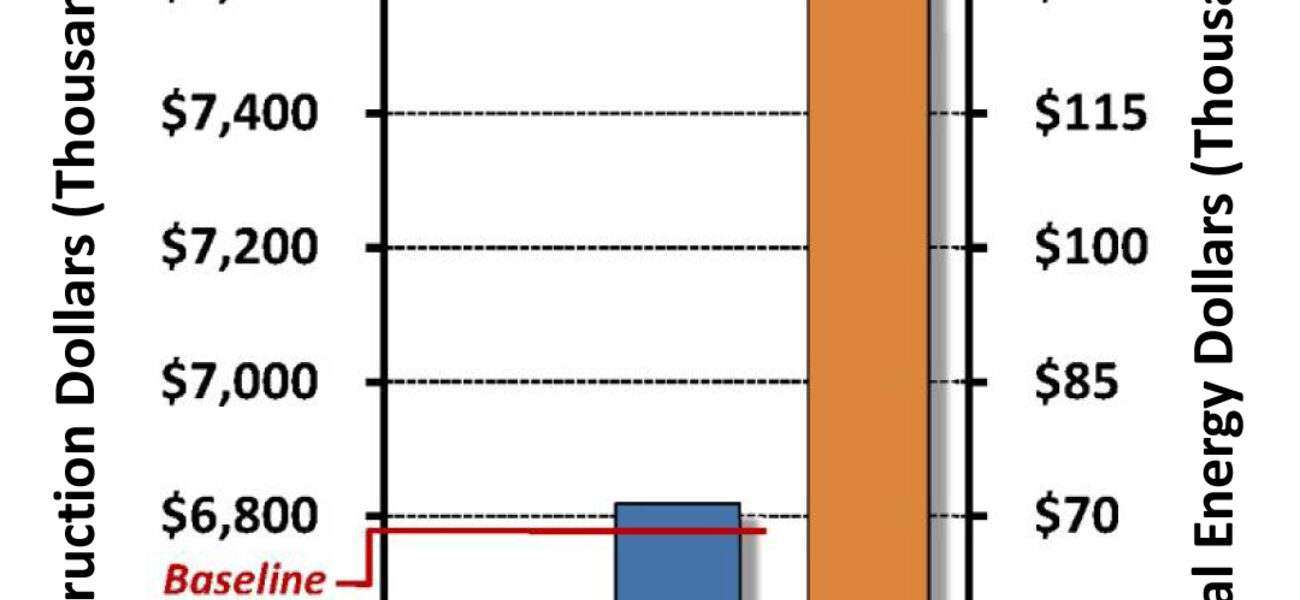

From an HVAC standpoint, the biggest savings come from reducing ceiling heights. Limiting the spaces’ volume reduces the amount of air, meaning fewer air changes are necessary. A 9.6-foot ceiling height saves $5,800 in construction costs alone over a 10-foot one, and $2,000 in annual energy savings. Dropping another several inches results in further savings, although these design decisions are also driven by a facility’s practical needs, such as equipment or cage rack heights, interstitial space, or the number or type of overhead pipes needed.

Taming the Energy Hog

“It’s just the nature of animal research buildings to be energy hogs,” says Golubski. “So although there is a lot that you can do with the building envelope, the greatest savings comes from the highest-efficiency mechanical systems.” While the University was adamant about the runaround loop discussed above, Clark Enersen did look at two alternatives that might be appropriate for other facilities. “Energy recovery wheels are about 77 percent effective versus a runaround loop’s 48 percent,” says Golubski. “In addition, they’re very easy to clean, either with a high-pressure washer or even just with a brush.” At the middle range of the spectrum, fixed plate air-to-air heat exchangers are about 60 percent effective, and heat pipes are 55 percent.

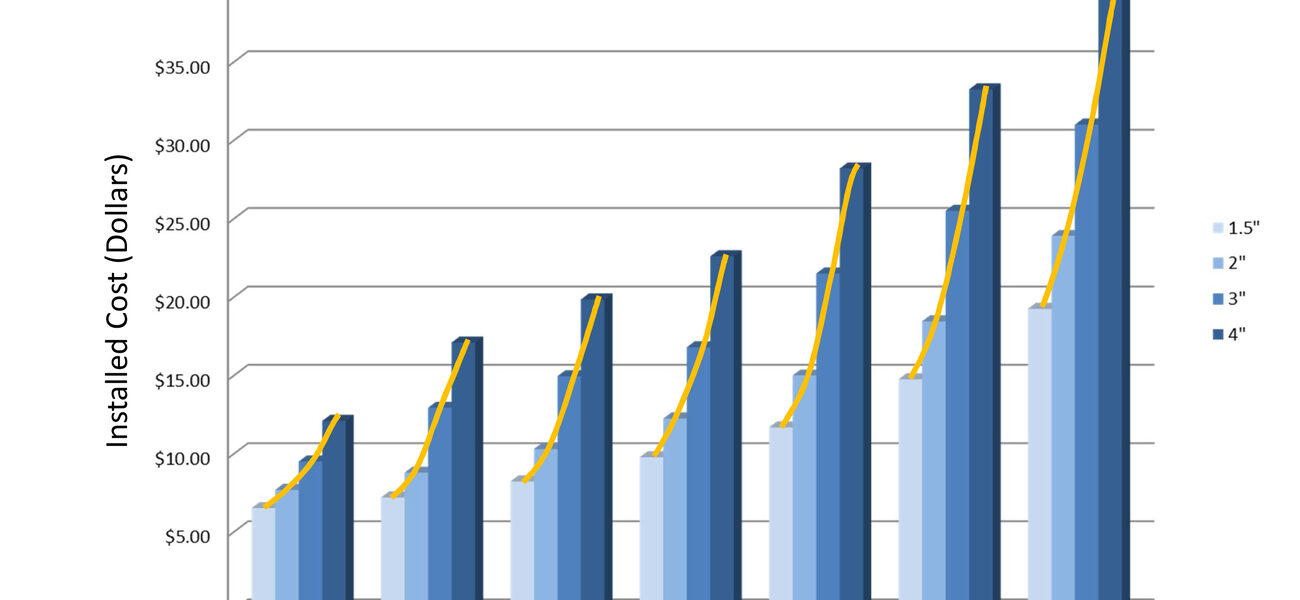

Pipe insulation requirements have increased under ASHRAE’s latest iteration, although not as dramatically as some other guidelines. “In 2007, it was a no-brainer to just add some insulation to decrease heat loss and improve efficiency,” says Golubski. “But with the new standards, smaller pipes need an additional half-inch of insulation, and larger pipes a full inch.” Insulation material cost rises by a greater factor for larger pipes, as insulation materials increase. The annual energy cost falls with increased insulation, but because of the much greater material and installation cost, the simple payback extends into a much fuzzier future. “Again, this will vary depending on the facility’s other considerations,” Golubski says, “but basically it requires more analysis than previously to ensure good ROI.”

See No Evil, Hear No Evil

Lighting quality, power density, and energy efficiency are additional sustainability (and LEED rating) concerns for many animal research facilities. LEDs, increasingly popular because of their longevity and reduced energy consumption, are generally more expensive than fluorescent fixtures, but their long-term energy savings can outweigh the initial cost depending on the application. However, these facts are complicated by the additional need to minimize light-related impact on the animals themselves.

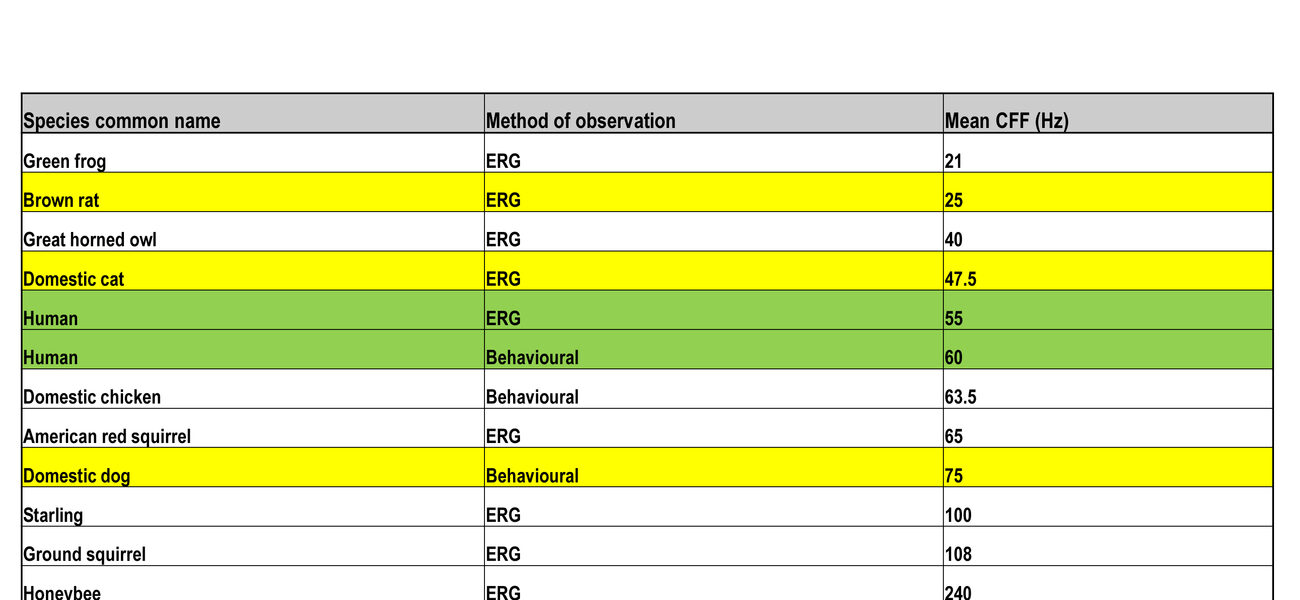

The negative effects of flicker in humans are well documented and include headaches, eyestrain, and even epileptic seizures. But different species are affected at different frequencies. “Brown rats show electroretinographic changes at 25 hertz. The domestic cat is at 47.5 hertz. Dogs have significant behavioral changes at 75 hertz,” says Walter.

Both blue and cool white LED light have been shown to damage albino rats’ retinas after nine days of exposure. Filtering blue LEDs—with remote phosphor, for example—can help mitigate these effects. “Basically, before utilizing LEDs, you want to review and analyze color temperatures and filters and talk with the product specifier so that they know to look for these things,” says Walter. “I think the technology is definitely taking over, but at this point we still need to be cautious with animal applications.” He does note that the energy savings are compelling—0.86 watts less per square foot for comparable brightness and clarity to fluorescents, based on one holding room photometric study. With the many factors influencing lighting decisions, he says, “maybe the best application for LEDs right now is for areas where the lights are either all-on or all-off most of the time, or for procedure rooms. These areas’ dark cycles reduce lighting power densities regardless of the source.”

One other concern resulted in a lesson learned during the renovation of the university’s lower-level animal facility. “Our initial noise analysis didn’t raise much concern,” says Golubski. “But after construction, we found some unanticipated rumbles from an exhaust fan that were making their way into the space.” Low frequency sound ranges affect rabbits, one of the primary species the facility houses. The solution was a sound attenuator, designed to prevent the noise from transmitting down through the ductwork. “You need to be cognizant of what frequencies and parameters are disruptive to the species in question,” says Golubski. Other solutions he recommends include diffusers with low sound discharges, or selecting larger fans that run at lower speeds. “Occupancy sensors tend to put out 40 kilohertz, so you also want to avoid putting those in your holding rooms or in places where they transmit into the vivarium,” he says.

As it becomes more stringent, the ASHRAE 90.1 challenges engineers to stay abreast of leading-edge materials and techniques. Awareness of the continual changes to the code is critical for projects keen on obtaining LEED certification. But Golubski and Walter find that presenting a wide range of options for energy savings—satisfactory, good, better, and best—helps clients make decisions. “Evaluate all your building systems when looking for energy savings,” says Golubski. “Try to get all parties involved from the very beginning, and be sure to talk about pitfalls you have seen in the past.”

“We’re not saying that there’s necessarily a right way and a wrong way to do things,” says Walter. “But those construction costs, and especially energy costs, do add up to more money left in your pocket.”

By Liz Batchelder

This report is based on presentations Golubski and Walter gave at Tradeline’s Animal Research Facilities 2014 conference.