The Massachusetts Institute of Technology was facing high demand and frustration among students and faculty unable to access its more than 40 maker spaces, even during non-conventional hours. After evaluating the logistics related to those spaces, totaling 120,000 sf, they developed a new app that illuminates the existing maker spaces, then enlisted the help of student volunteers to oversee some spaces into the evening. MIT also plans to add another 20,000 sf of functional space.

MIT students and faculty firmly believe that the educational experience should include a balance of in-classroom theoretical learning and hands-on making, experimenting, and building, in keeping with the university’s motto: Mens et Manus, Latin for “Mind and Hand.”

Making takes on many forms on the campus of 11,000 undergraduate and graduate students. Engineering classes frequently require individual students or teams to create functional objects that solve real-world problems and demonstrate scientific principles learned in lectures. Making has been part of MIT’s DNA since its 1861 founding. Student clubs and organizations, in keeping with the school’s motto, are also eager to build for the fun of it.

The maker spaces, covering an area roughly the size of two-and-a-half football fields, fit into three basic categories:

- Machine Shops require experienced, trained technicians, and are ideal for large-scale research projects and those that require specialized equipment and skills.

- Project Spaces have traditionally been used by academic courses, one challenge being that students lose access to the spaces once the course ends.

- Community Spaces, the most accessible of all, are mostly operated and used by students. While they have the widest possible uses, they represent only 5 percent of all maker spaces on campus.

Challenges of Time and Scheduling

Despite the massive amount of space available, there have been difficulties with access to the maker spaces.

“Students were constantly complaining that they were not able to get access to the facilities to build things,” says Jonathan Hunt, who helped craft the solution. “Faculty were complaining that their graduate students and researchers weren’t able to get training in order to use the existing facilities on campus.”

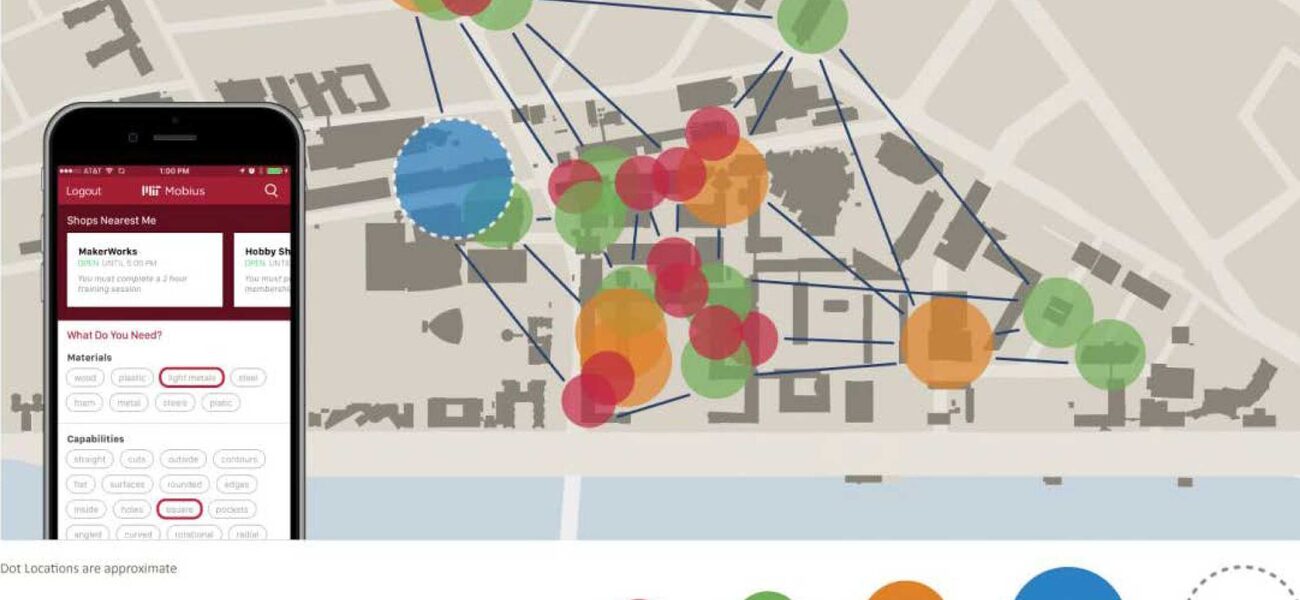

To address the problem, MIT established Project Manus in 2015, with a mandate to create the gold standard in next-generation academic maker spaces. Hunt, the associate director and maker IT guru for Project Manus, along with the team, oversaw the creation of Mobius, the app that provides a one-stop window into maker spaces, offering search capabilities, training materials, and the ability to pay for materials and usage fees.

Hunt and the Project Manus team, helmed by mechanical engineering professor Martin Culpepper, spoke with the maker space administrators and managers, as well as students, and discovered several disconnects:

- Lack of information. Most of the spaces did not have readily available information about when they were open for use, what equipment they offered, how to become trained, or how to schedule access.

- Timing. Students wanted to use the spaces when they were done with classes and into the evenings, times incongruent with full-time employees working traditional daytime hours. Hunt pointed to an energy usage study that showed dorm electricity use begins to ramp up at 6 p.m., peaks at 11 p.m., and remains high until 2 a.m.

In the summer of 2015, the team surveyed MIT students about maker space usage. One of the most telling findings was that students most often made things in their dorms and off campus, which alarmed the university’s Office of Environmental Health and Safety and inspired them to partner with Project Manus.

Some of the findings came as a surprise. For example, only 26 percent of students wanted the spaces open 24 hours a day. During weekdays, the top two time periods sought were 7-10 p.m. (42 percent) and 4-10 p.m. (35 percent). Only 19 percent wanted the spaces open from 10 p.m. to 1 a.m.

The team was also surprised to learn that the most popular places for students to do their making were their living space—bedroom or common room (55 percent) and off campus (20 percent).

The team began using a simple iPad sign-in process in some maker space locations to understand what spaces were being used, when, by whom, and for which purposes.

“The data collection has been going on for a little over a year, and we are beginning to analyze it,” says Hunt. “Since we do not have a mandate to have the iPads in every space, the data is incomplete, and it would not be appropriate to make judgments about which kinds of space are most popular at this point.”

As a result, MIT hasn’t altered the kinds of spaces it offers, or discontinued any of the existing spaces.

An Application for Information, Two New Spaces

Armed with usage information, audience needs, and an understanding of campus culture, the team set out to build an app—Mobius. The app, which launched in 2016, allows users to find when spaces are open; learn whom to contact; obtain training; and pay for materials and machine time, using either a credit card, departmental purchasing card, or the university’s student currency. Today, Mobius has 1,800 users, and Hunt hopes to grow that number to 3,500, which would represent about 30 percent of the student population.

The many grant-funded research projects using the spaces created additional complexity for making. The team is working to improve the options for collecting payments, some of which still use paper systems.

The university has also opened two new maker spaces designed to improve access by empowering students to offer coverage and training. MakerWorkshop is a 1,100-sf space run by graduate student volunteers. And MakerLodge is an 850-sf site run by undergraduate volunteers, and designed to teach freshmen about maker technology. In its first year, 500 students started training at the MakerLodge; those who complete the training receive $100 in MIT currency.

Student workers and volunteers advise, teach, and help other students learn about the decision-making involved in sound engineering and manufacturing. Students learn about accountability, training, mentorship, patience, and leadership.

Hunt considers the two new spaces to be major successes. He and the team are working with students to assess the first year of MakerLodge, and has already identified opportunities to improve training on certain processes, such as 3D printing.

Using student volunteers has also allowed for considerable scaling up of usage. Opening a new machine shop, notes Hunt, requires hiring another technician who can reasonably supervise four or five students at a time, supporting about 100 users per year. In contrast, in a student-run shop like MakerWorkshop, 40 to 45 student mentors volunteering a few hours a week can serve more than 600 students, train additional volunteers, and allow the space to be open during peak-demand hours. The team estimated it would take about 14 full-time employees using traditional approaches to train the entire freshman class at MakerLodge; the 50 student volunteers trained about a third of the class.

Students praise the ease of use the app provides and the university’s investment in their hands-on learning needs. Working on actual projects helps them see concepts, create and experience end-to-end engineering principles, and begin the type of work that will be a part of many of their future jobs.

Next Steps

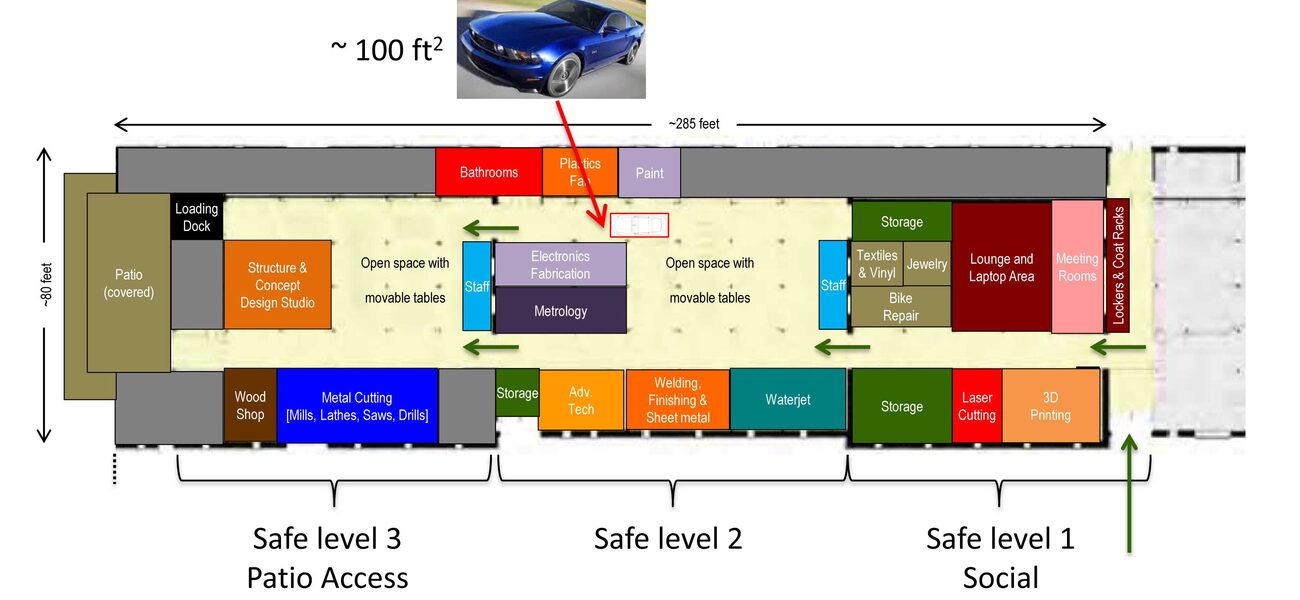

The university is looking to add another 20,000 sf of space by converting an old warehouse to a maker space. Initial plans will use first-floor space in a five-building complex, which had previously been slated for new dormitories.

The warehouse site will feature a range of shops, including:

- 3D printing

- Laser cutting

- Waterjets

- Welding, finishing, and sheet metal

- Metal cutting

- Woodwork

- Electronics fabrication

- Design studio

- Textiles and vinyl

- Jewelry

- Plastics

- Paint

The space will have other amenities designed to make it attractive and welcoming to users, including meeting rooms, lounge spaces, a covered patio, open workspace with movable tables, a loading dock, and storage.

Hunt notes that having a friendly space is important to reduce the intimidation factor that can turn off some would-be users. Case in point: The warehouse maker space will include a bicycle repair section.

Given the school’s history, Hunt is convinced that maker spaces will continue to be an essential part of the MIT student experience.

“We learn with both theory and practice” he says, “often by moving back and forth between the theoretical and the hands-on—balancing how much time a student spends learning the science and math behind the engineering and the time spent building. We think it’s core to have both.”

By Kevin Wesley