The University of Toronto spent $153 million (USD) to rehabilitate 47 percent of its total research space, a move that is favored by the Canadian government as a viable alternative to building new facilities. It is estimated that constructing new buildings to replace this amount of the university’s aging research facilities would have cost approximately $494 million.

“We proposed what the government wants universities to do—rehabilitate existing infrastructure as opposed to building new facilities,” says Scott Mabury, vice president of university operations. “Many of the projects we did were in buildings that were more than 50 years old, and the labs could no longer adequately support modern research activities. The updated labs will benefit approximately 5,000 students and 1,100 researchers who use them each year.”

The initiative features 56 projects involving 570 labs with a combined total of 592,000 sf in 17 buildings. The upgrades impact nine academic divisions with improvements to the medical, dental, biology, chemistry, and engineering labs. The infrastructure investment will create world-class facilities that empower researchers to do their best work, provide a learning environment that motivates the next generation of researchers, and bolster collaboration across disciplines.

It is estimated the improvements will save the university more than $2 million in annual utility costs. In addition, the annual carbon dioxide emissions will be reduced by more than 5,900 tons, working toward the university’s goal of decreasing greenhouse gas emissions by 30 percent before 2030.

Working Under a Tight Deadline

The work was financed through the Strategic Investment Fund (SIF), the Canadian government’s investment in the infrastructure of universities and colleges, with additional money coming from the University of Toronto and the province of Ontario. The program is intended to fuel the national economy by helping forward-thinking universities upgrade their research facilities, thereby enabling them to attract and retain top faculty and students.

Applying for funding from the federal government means complying with what Mabury calls “the new paradigm of five weeks.”

“The recent practice of the government is to announce a funding opportunity and provide five weeks or so to apply/respond,” he says. “It’s happened multiple times, and we need shovel-worthy and shovel-ready projects that we’re able to submit.”

The university submitted its project proposal to the government in May 2016 and received funding confirmation two months later with the caveat that all projects be completed by April 30, 2018. Most of the projects began in September 2016 and the first ones were completed in August 2017.

The university met the deadline, with some projects being completed on the final day, by using a team approach to encourage buy-in from all stakeholders and refusing to grant extensions to any of the 21 contractors, 25 prime consultants, or 26 project management staff.

“It’s difficult to obtain philanthropic funds to rehabilitate old labs, and this program was an opportunity to get a dollar-for-dollar match,” says Mabury. “I did not grant any extensions because we wanted to be a trusted partner to the federal government, and we needed to deliver the project on time and on budget, because the point of this investment is to energize the economy. I said early on that I would pull any project that was going to be late, and the dean would have to cover that cost entirely on their own.”

The university uses a responsibility centered management (RCM) budgeting system, where the deans are accountable for generating revenue to cover project costs for their particular academic unit. An outside project manager was hired to oversee the improvements and to serve as the main intermediary between university officials and the government.

Noteworthy Improvements and Challenges

Mabury says working to complete a seemingly impossible task with a seemingly impossible timeline gave stakeholders the impetus to work together to meet the stringent deadline. Along with adhering to an accelerated schedule, the project team completed the work in facilities that remained occupied. Special care was taken to ensure occupants were not bothered by noise, dust, odors, or vibrations.

“It was a challenge to complete the projects while 6,100 faculty, staff, and students were working in these buildings, but the fast-paced schedule helped,” says Mabury. “It was a requirement for everybody to come together and put up with things they wouldn’t normally tolerate. I think it was a more successful project than if we'd had an extra year and didn’t have this ambitious schedule.”

In some cases, occupants had to leave the building for three weeks while specific work was being done, but Mabury notes the alternative was to shut down the building for 18 months. There is no swing space available to accommodate faculty during renovations.

In other cases, challenges occurred regarding permitting issues, jurisdiction of various authorities, and code compliance.

“With 56 projects here, and with every other post-secondary education institution in Toronto also having projects, the city was extremely challenged to address these issues,” notes Mabury.

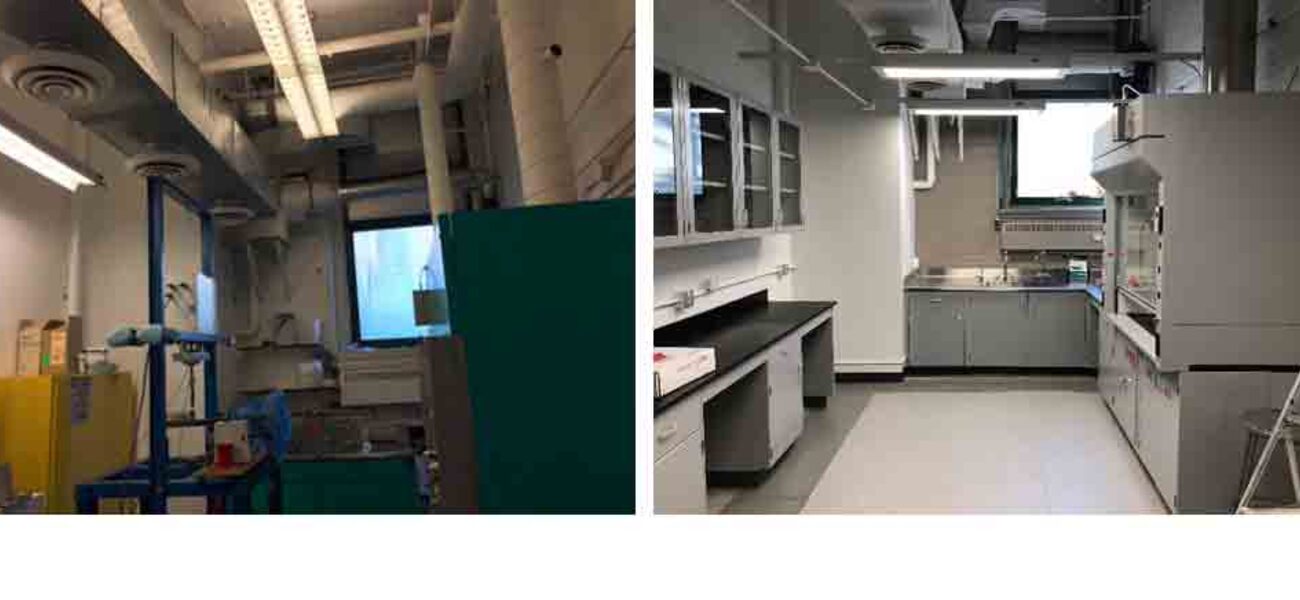

Challenges were handled as they arose, and substantial changes are now evident in the university’s research labs, including upgraded electrical systems, LED lighting, new HVAC systems, better mechanical systems, and new generators. Each project included specific goals, as well as expected and sometimes unexpected obstacles.

School of Dentistry

This 1950s building was less than inspiring, with 95 small, cluttered labs; the space has been renovated to feature 23 open labs in an environment that promotes collaboration and productivity. The team encountered unanticipated site conditions and building code requirements related to non-working or nonexistent shutoff valves and the presence of asbestos. These challenges were overcome by quick decision-making and a team that understood the importance of the work. Despite setbacks, the project came in $7.5 million under budget.

Faculty of Medicine

The Medical Sciences Building includes 1,900 rooms, 1,500 of which are occupied. The project involved removing 37 of the 310 labs and renovating the remaining 273, but only after 24 were completely gutted to remove asbestos. During the removal, a sprayed fireproof insulation caused a BSL-3 breach that went undiscovered for several days. The cleanup delayed the project schedule by six weeks and cost $1.8 million.

A reputational risk management strategy was employed to alleviate the concerns of internal and external stakeholders. Temporary air monitoring stations were placed on all floors, and more than 4,000 air sampling tests have been done.

Scarborough and Mississauga Campuses

The mechanical and electrical systems were upgraded in the vivarium building at the Scarborough campus, and the number of labs was increased from 20 to 55. The vivarium has been revamped to meet the need for increased housing, behavioral testing, and surgical capacity. A BSL-2 animal handling facility also has been developed. Portable furniture is used to offer flexibility for a variety of space configurations. The overall project ended at $1.1 million over the budgeted cost of $13.5 million, but there was money available to cover the difference.

An outdated building on the Mississauga campus was demolished, and an aquatics research facility was built to support the work of 95 researchers.

School of Engineering

With seven buildings requiring lab enhancements, the engineering project was the most difficult. Mabury points to a lack of preparation and inaccurate cost estimating due to the extremely tight timeline as primary reasons this project was so demanding. The number of fume hoods was increased to permit more experiments to be conducted simultaneously, and environmental controls were added to protect sensitive equipment. The upgrades coincide with the opening of the new Centre for Engineering Innovation and Entrepreneurship.

Lash Miller Chemistry Building and Ramsay Wright Biolabs Building

The Lash Miller building, dedicated to chemistry research, relies heavily on fume hoods. Prior to the renovation, there were 173 fume stacks on top of the building, but now there are only three stacks, and the building was converted from constant volume to a variable volume.

The number of labs was increased from 26 to 65 in the Ramsay Wright Biolabs Building, and the HVAC system was upgraded to meet current code requirements.

Project Takeaways

Completing such a large project requires comprehensive planning, input, and buy-in from stakeholders, coupled with the ability to keep the work on schedule and under budget, even in the face of challenges.

“Trouble will erupt in these kinds of projects when you are moving fast,” says Mabury. “You need to engage project champions that you can rely on. These supporters make all the difference and assist the group responsible for delivering the project.”

Mabury knows the importance of identifying consultants and contractors who are interested in collaborating to deliver high-quality projects at reasonable costs, rather than viewing each project from a perspective of fees and profit. Finishing this initiative with no extensions helped the university determine which contractors and consultants are reliable enough to hire for future projects.

“We need to have people we can rely on, because there is a lot of work at the university,” says Mabury. “This has been a very successful project, and it is already helping us attract and retain talent.”

By Tracy Carbasho