In December 2016, Stony Brook Medical launched a plan to build housing for a pair of high-power MRIs, an older model 9.4-Tesla and a newer 7-Tesla. The original plan was to build a brick-and-mortar facility into their existing vivarium, but that was deemed too expensive, forcing them to consider other options. Glen Itzkowitz, dean of facilities and operations, and his team decided to pursue an option that had never been considered at Stony Brook—using pre-fabricated containers to house the MRIs, which they could just barely squeeze into a loading dock underneath a high-traffic footpath, space that was largely being wasted.

Stony Brook purchased the 9.4-Tesla MRI jointly with Brookhaven National Laboratory in 2005, where it was housed until BNL cancelled its high-energy medical physics program. The MRI was decommissioned in 2016, leaving it available for transfer to Stony Brook. Around the same time, Stony Brook was undergoing an effort to reinvigorate its medical research enterprise. It established five pillars of excellence in medical research, one of which is imaging.

“They led a groundswell effort to have a minimally invasive small-animal imaging core be a part of one of those five pillars,” says Itzkowitz. “The effort was taken at the same time to bring this 9.4-Tesla back online at Stony Brook,” which was subsidized by a $500,000 grant from the Empire State Development Corp.

The new 7-Tesla was needed to support a researcher that Stony Brook was recruiting from another institution.

Site and Design Considerations

Because of the size and weight of the MRIs, they had to be placed at ground level, and preferably close to the vivarium to facilitate their use on small animals. The original plan was to build a brick-and-mortar facility behind the large-animal operating theaters, which was a desirable location near both the vivarium and a new ASBL-3 facility, and because it is what Itzkowitz describes as an “animal hub.” However, the construction would also have put the large-animal operatory out of commission for a considerable amount of time. Ultimately, cost was the largest consideration—$3.7 million for infrastructure, core and shell, and fit-out (excluding equipment), plus addressing security and safety issues.

But the location was attractive—on the ground of an underutilized loading dock area that, at the time, was being used to store construction materials. It was essentially wasted space. The downside is that the space under an active footpath is very restrictive, giving it very low overhead clearance. Prefab containers were the unlikely solution.

The Prefab Pitch

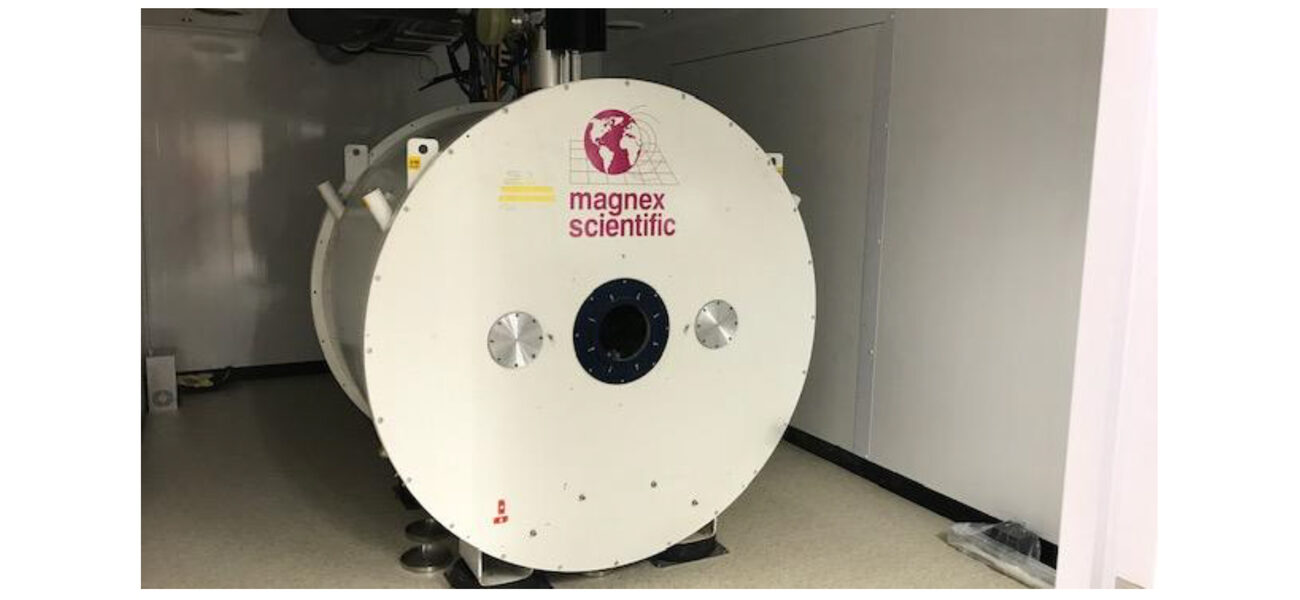

Bruker engineers, of Billerica, Mass., suggested utilizing prefab containers, which have been used for years to house mobile and non-mobile human MRIs, to house the MR systems. “The question was, can we do the same on a non-mobile chassis for high-field, small-bore animal systems and meet a budgetary threshold?” says Itzkowitz. “They had suggested a containerized solution, and it was really just an out-of-the-box concept for us. We had never considered it.” With a small deposit to the vendor—Medical Coaches of Oneonta, N.Y.—the containers were secured in a queuing position in August of 2016. The structure was to be completely self-contained, so that everything for small animal prep and to maintain the MRIs—MR operations, electrical rooms—would be built in. With minimal overhead clearance between the prefabs and the walkway, it was necessary to have all of the mechanical connections housed inside. The two containers were delivered for $600,000; add to that $500,000 in site work, plus mobilization, demobilization, and soft costs, the total cost was about $1.5 million—less than half the projected cost of the brick-and-mortar design.

Bruker engineers did not want the MRIs to be transported inside the prefab containers, so they were shipped separately and placed inside on site, through a series of removable panels on the sides of the containers. Once situated, all mechanical connections inside the prefabs were fed through umbilical MEP feeds and mains to the containers, which provided electrical service, water, water rinse, sanitary out, tele-data, building management system, and intrusion alarms. The quenching for the magnets had to be dealt with separately, with a 60-foot quench duct running across the ceiling of the loading dock, then running vertically another 30 feet before reaching a buffer. One concern was the need for the older, 9.4-Tesla to be cryogenically re-liquified after charging the magnet. In a typical MRI facility, a tech could climb to the top of the magnet once a month and manually refill it with liquid helium and liquid nitrogen, but this wasn’t an option with the prefab containers because of the height restrictions. The solution was a helium recovery reliquifier system from Syracuse-based Cryomech.

One of the most important factors to consider with the MRIs was shielding, especially with the location underneath the footpath. The 7-Tesla is a Bruker magnet that is actively shielded, therefore it requires less infrastructure and has the smaller footprint of a 5-Gauss line, whereas the 9.4-Tesla has only a passive shielding system. Stony Brook worked with ETS-Lindgren, which came up with several shielding designs, and then worked with the engineers at Medical Coaches to design a way to build the shields into the panels of the prefab. The panels can be removed for servicing purposes.

Successes and Lessons Learned

While it was ultimately cost-effective and space-efficient to house the MRIs in the loading dock, it was a very tight space, and was frequented by pigeons and their messes. This was “not an easy learning curve for delivery companies and service companies,” says Itzkowitz. Partly because of this difficulty coordinating traffic, the 9.4-Tesla was placed outside of the originally planned Gauss line footprint, (it was installed after the 7-Tesla), which necessitated an increased perimeter and greater security around the site.

Itzkowitz stresses the importance of planning in construction projects such as these: “This was 80 percent planning, 20 percent execution. At any one given time, we were managing 11 contracts—including the prefabs, MRI manufacturer, the cryogenic liquifier systems, pre-action fire protection, and quench vent—in a small project management group.”

But the success of the project, says Itzkowitz, proves that, “it is possible to repurpose languishing space for high-end modalities.”

By Anita Woofenden

| Organization | Project Role |

|---|---|

|

Bruker

|

7-Tesla MRI

|

|

Medical Coaches

|

Pre-Fab Containers

|

|

Cryomech

|

Helium Recovery System

|

|

ETS Lindgren

|

MRI Shielding

|