Envision a highly adaptable, flexible, and sustainable research building, with maximized lab square footage and a thriving, collaborative, and cross-disciplinary environment. Arizona State University attained this vision of a workhorse facility through a first-time building delivery partnership. Both the vision and its realization focus on answering one question: How much research space can we get? “Through the lens of a ‘space manager,’ I’m always trying to get the highest and best use of space out of the university’s available square footage,” explains Erik Halle, senior director of Research Facilities and Infrastructure at Arizona State. “With Biodesign C, we wanted to see how far we could push that.”

Past Metrics Chart the Future Path

In 2012, ASU began reviewing nearly 10 years’ worth of metrics on construction, renovations, space usage, and maintenance of existing buildings in its Biodesign Complex. At the time, the university was not actively planning for its next research building. But through the synthesis of multiple studies focusing on various aspects of the school’s utilization of almost 4 million nsf of research space, Halle and his colleagues distilled a key theme: The cost of owning and operating ASU’s research buildings was significantly greater than the not insignificant costs of building those facilities in the first place.

“The studies collectively illustrated that a lot of things were happening in our spaces after we built them. Not only were the researchers changing, but research programs were changing,” shares Halle. “Historically, ASU delivered beautiful buildings with great architecture, but the historical data showed we had an opportunity to focus on the metric of getting the most out of a building. We became very interested in trying to improve on our timeframes and costs for putting people into our research spaces.”

Getting “the most out of a building” also meant that the university wanted to better its historical research space metrics of 46.9 percent net-to-gross sf and 23.5 percent lab net-to-gross sf. Additionally, says Halle, with future buildings, ASU wanted higher use of that increased net research space, to meet a projected $700 million research expenditures goal by this year.

“We needed as much lab space as possible to which we could attach research grant dollars, and, simultaneously, the metrics showed any future buildings needed to maximize indirect cost recovery,” explains Halle. Not all federal contracts and grants would generate overhead funding for research and, even though ASU is a thriving and expanding public university, the addition of 1.5 million gsf of new research space since the early 2000s is being financed by the success of the researchers and the growth in research expenditures, and not by public funds.

Aspirations and the Mission

Armed with the data from the Biodesign Complex’s past, an aspirational roadmap for future buildings started taking shape. By 2016, ASU knew that the next building to be constructed needed to be a highly collaborative and transparent environment, with adaptable and flexible research space and maximized lab square footage that would foster growth and interdisciplinarity of the university’s research. The facility also needed to attract the best and the brightest researchers from around the world. Halle and his team, together with stakeholder groups from across the university, aligned around their aspirations and drafted a mission statement.

“I don’t believe we’d ever had such a clearly thoughtful process and mission statement before, when considering construction of a new research building,” says Halle. “But we had one for Biodesign C six months before we’d hired a design firm or a contractor.”

“A lot of projects we undertake are much less defined, which takes a certain amount of energy and effort to begin,” explains Chris Conaway, a principal architect at ZGF Architects. “In this case, the project already came with excellent definition and direction, allowing us to get started more quickly on what was a fairly aggressive schedule for design and construction.”

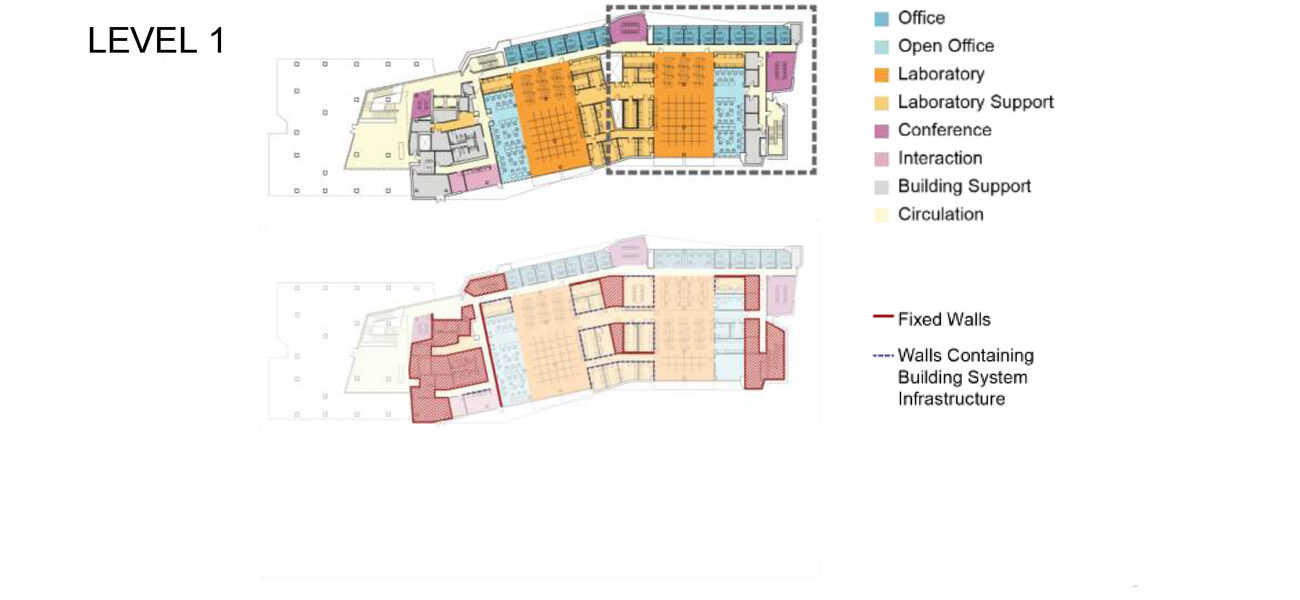

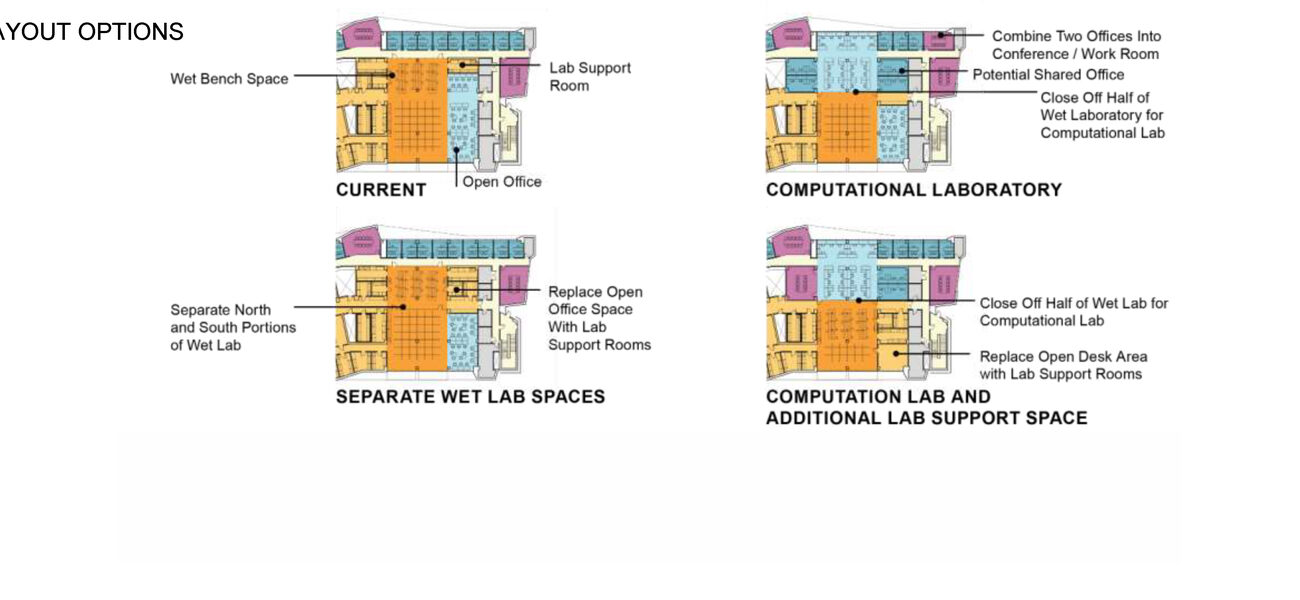

Meanwhile, Halle and the ASU team knew they could realize a 20 percent space savings with collaborative open laboratory space instead of walled laboratories, and that those spaces would make future renovations easier and cheaper. The university had a $120 million budget for Biodesign C, with 80 percent of the funding slated for bricks and mortar, which was about a 10 percent increase from typical budgets for new research buildings. ASU didn’t have a definite number of researchers assigned to the proposed building, but it did request as much research capacity as possible on all six levels, with few common and open spaces. There are 13 conference rooms, all with videoconferencing capabilities.

“The trend for some time has been toward providing more and more common spaces in the hopes of promoting cross-disciplinary encounters,” says Conaway. “Here we took a different approach to encouraging interactions among researchers and staff.”

One solution was to incorporate a neighborhood concept in the design. Floors three, four, and five are organized into three neighborhoods each, giving the university flexibility to reconfigure the space as researchers come and go—a critical design feature, as some research buildings saw a nearly 100 percent churn over 10 years. The neighborhoods also provide the opportunity for collaboration across disciplines.

Each neighborhood is 7,500 sf, with 4,500 sf of lab space, eight 120-sf offices, and six PIs; the ratio of open lab to lab support is 50-50. The floorplate is a fairly narrow 90 feet, which allows a lot of natural light into the interior of the building.

The second floor, which is organized into two neighborhoods, contains the fume hood-intensive chemistry labs, programmed for 48 hoods. The remaining 11 neighborhoods can accommodate as many as 77 fume hoods.

ASU compensated for the lack of open and common space within the building by leveraging the amenities available in adjacent facilities in the complex. “Researchers can borrow communal space from nearby Biodesign A & B buildings to get away from their own desks and labs and interact in a different way,” says Estephanie Graham, an associate architect at ZGF.

Proof of Performance: Payoffs and PIs

Biodesign C opened with substantial completion and occupancy in April 2018, and soon will reach 90 percent capacity. Halle and his team have been happy to realize success in several additional metrics and accolades:

- The building’s design achieves 54.8 percent net-to-gross sf; within the lab spaces, the ratio is 36.9 percent net-to-gross sf.

- Strategies for 100 percent facility reliability and aggressive sustainability, along with long-term operations and maintenance efficiency, has earned Biodesign C a LEED Platinum certification and an expectation that the structure will cost $350,000 less to run annually than the second-most efficient research building at ASU.

- The new facility houses a similar number of PIs as Biodesign A & B combined but uses 40 percent less space than those two buildings.

And the increased lab square footage and resulting utilization in Biodesign C is having the desired effect on research expenditures, according to Halle.

“By implementing an aggressive construction cost analysis and increasing the proportion of the project appropriated toward construction cost, we ended up designing a 191,000-gsf building from the onset, rather than the initially programmed 155,000 gsf,” he states. “The way we used the space yielded 71,000 sf of lab space, compared to 37,000 sf in the smaller structure.”

Mission Statement as Touchstone

The ASU-ZGF team believes that the successful design, construction, and usage of Biodesign C has as its foundation the university’s mission statement. The clear mission statement was one of the critical success factors that made the project run efficiently, helping to the team to quickly come together and continue pulling toward the same goals throughout the process, say Conaway and Graham. For Halle, as well, the process of working while grounded in the mission was key.

“This building is such a success on so many levels in so many ways, not the least of which is our ability to perform a vast amount of research in the place, which enables ASU to recruit talent from all over the world,” says Halle. “But that’s rooted in how well this team performed, creating a new and exceptional building delivery process. We were making those important, aspirational decisions regarding Biodesign C together and speaking as one to the design and construction team.”

By Ellen Gamble