Rutgers University’s new 110,000-sf, $84 million Richard Weeks Hall of Engineering, designed by The S/L/A/M Collaborative (SLAM) and opened in 2018, provides state-of-the-art teaching suites and labs for concept development, pilot manufacturing, high-bay testing, rapid prototyping, and microfabrication in an interdisciplinary environment that serves students, faculty, and industry. In addition to smart classroom configurations, flexible learning laboratories, and collaborative work space, the building itself serves as a lab and allows for data gathering and hands-on learning. Rutgers’ 2014 strategic plan identified its School of Engineering as central to the university’s growth and success, and this LEED Gold-certified facility represents the first step in a physical master plan that supports both the school and university strategic plans.

With 3,991 undergraduates and 1,061 graduate students, Rutgers School of Engineering is the top public university for undergraduate engineering in the New York-New Jersey metro region, according to U.S. News & World Report. It is served by 300 faculty and staff in seven departments offering 11 degree majors, including aerospace engineering, which was added as a degree option in 2016 and has 175 students. Faculty and administrators are now part of the Big 10 Academic Alliance network, and the school has $75 million of research funding (2017 Higher Education Research and Development). The school’s 2017 graduates had an 87 percent job placement rate within six months after graduation.

When Robert L. Barchi joined Rutgers as president in 2012, he was faced with myriad significant changes, including the merger of most of New Jersey’s University of Medicine and Dentistry into Rutgers. At the same time, Rutgers was beginning its largest capital construction campaign, entering into the Big 10, partnering with the state’s largest healthcare system, and undertaking significant changes in administrative systems and divisions. Barchi initiated a strategic planning process to guide the university, which resulted in the focus on the School of Engineering.

The School of Engineering then created its own strategic plan that set five goals to:

- be recognized as one of the nation’s top engineering colleges;

- advance specialized and relevant research in advanced manufacturing, computing, healthcare science, energy, and materials;

- drive economic growth in New Jersey;

- cultivate an actively engaged Rutgers engineering community; and

- provide a capstone to the school’s excellence with a new engineering complex of sustainably designed classrooms, laboratories, offices, and common space.

Named in honor of a 1950 alumnus, Richard Weeks Hall is the first completed building in a multiphase project aimed at enhancing engineering’s campus presence by providing leading-edge labs inside an iconic structure. In addition to classrooms, lecture halls, and labs, the building houses the school’s civil and environmental engineering program, development and alumni, the dean’s office, and the New Jersey Advanced Manufacturing Institute—bringing together people from disparate engineering disciplines and welcoming non-engineering students and staff.

“Everything about the building is to allow collaboration between faculty of multiple units and to provide inspiring spaces both for our students and potential students,” says Thomas Farris, Ph.D., dean of the School of Engineering. “This is the new gateway to the engineering precinct, and it’s viewed by students on campus as the place to be. All of the facilities aimed at welcoming students and giving them a place to socialize and study together have been a huge hit. It’s completely changed the way that we can recruit potential students and welcome them when they’re here.”

Supporting Strategy with Physical Master Plans

Throughout its 250-year history, Rutgers has grown by combining colleges and acquiring land throughout New Jersey. With a total of 960 buildings, The university’s five campuses in New Brunswick now span 5.6 miles and six municipalities, and the statewide footprint covers 6,100 acres. Because many colleges became one university, a number of different campus centers existed amid suburban sprawl. While many universities can conduct a manageable campus-wide plan, that doesn’t work at Rutgers, explains David Schulz, AIA, PP, AUA, Rutgers University vice president of planning, development, and design.

“Physical master planning is a significant challenge,” says Schulz. “We realized that the master plan was just too big to not focus on distinct areas.”

Emphasis on specific geographic regions, or precincts, allowed Schulz and his team to build a more nuanced master plan that looked at buildings, technology, and transportation in each area. Weeks Hall represents the first of many phases to transform the engineering precinct on the Busch Campus in Piscataway. That campus is approximately 760 acres, while the engineering precinct takes up 30 acres surrounded and broken up by parking lots. Weeks Hall, with its modern, striking design, has become the School of Engineering’s gateway.

“This is one of the strongest projects I’ve worked on in terms of alignment of strategy, master plan, and execution,” says Schulz. “It began with clarity. Strategically, we knew why this project was important and what it needed to do. One of the gauges of our success on Weeks Hall is the number of students in there. As soon as it opened, they were grabbing lunch from the student center and hanging out here in the Weeks engineering building, even though they were not necessarily engineering students.”

Helping Students Flourish

To have a successful college experience, students need friends and mentors. Engineering students, in particular, tend to leave the major if they can’t make these connections, or if they realize it will take years before they can have an applied engineering experience. Rutgers’ goal is to provide both hands-on learning as early as freshman year and opportunities to meet a wide range of people.

“We can do things in the design of a building or planning of a campus, maybe even the layout of a classroom, that can help encourage people to meet one another,” says Kevin Herrick, AIA, principal, Higher Education Studio at SLAM. “The idea is to get as many collisions with people as possible, so that you have the most opportunity to find friends and connect to key faculty members. That means keep the building central, get lots of movement through the building, force people to bump into one another, and encourage inter-disciplinary programming and planning.”

Herrick adds that many thousands of people travel through the pedestrian walkways into the main quad where Weeks Hall stands. This not only helps meet the strategic planning goal of putting engineering on display but also welcomes students and staff from multiple disciplines into the building, where they can interact with one another.

"As social distancing influences our behaviors, it is even more important today to program safe collaborative spaces into facilities that will encourage meetings and interactions without compromising personal space, versus trying to reconfigure current building efficiencies to uncomfortable levels," says Herrick.

Promoting Active Learning

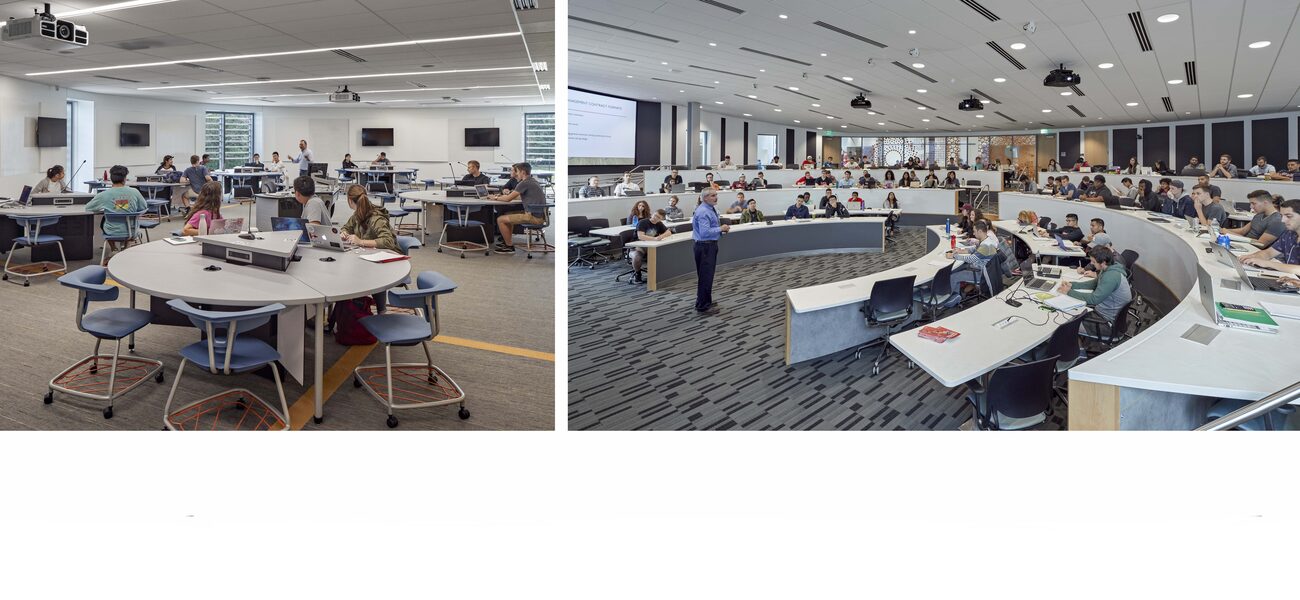

Though active learning is not new in academia, facilities can support the experience for both students and faculty. Three smart classrooms within Weeks Hall allow students to collaborate on projects. A 72-seat classroom has circular tables with computer support that allows students to project from their laptops or tablets to any of the monitors on the walls. A 144-seat classroom has seated rows built in a half-circle facing a podium where professors give lectures. Each seated level holds two tables, one in front of the other, and each chair fully rotates. A white board makes up the back of each second row. Instructors can impart information and give students problems to analyze together.

“Half the students in the room swivel their chairs, and they can partner with the people in the row behind them to do group work,” explains Schulz. “Then everyone returns to the lecture style to share results. It gives students a different type of engagement.”

Herrick notes that these types of environments call for additional space. Whereas a typical classroom requires 20 to 22 nsf per student, active learning spaces need around 28 nsf.

Sharing Labs

Labs in Weeks Hall were built with an open concept and are not assigned to a single faculty member. Civil and environmental engineering labs include an urban coastal water systems lab for modeling of coastal areas to develop and demonstrate flood risk reduction strategies for vulnerable urban communities; geo-environmental engineering labs focused on finding sustainable solutions for modern environmental and geo-technical challenges; and environmental process and molecular analysis laboratories with state-of-the-art instrumentation for measuring pollutants in air, water, and soil.

“As dean, I see the critical importance of shared research space and the value of resulting interactions between researchers from multiple disciplines,” says Farris. “I emphasize this 21st century approach to lab use with each faculty candidate I interview.”

Advancing Manufacturing

Weeks Hall is also home to The New Jersey Advanced Manufacturing Institute (NJAMI), established by Rutgers to promote and build upon the state’s manufacturing capabilities. The institute focuses on university–industry partnerships and is run by Alberto Cuitiño, chair of mechanical and aerospace engineering. Faculty and grad students work with industry partners to develop and test innovative devices in information technology, renewable energy, sensing devices, and health and life sciences. Students gain real-world experience, and businesses get help with research projects they might not otherwise be able to fund in the private sector. Ongoing costs to run the institute will be primarily covered by generating research projects, which are funded by government and industry grants.

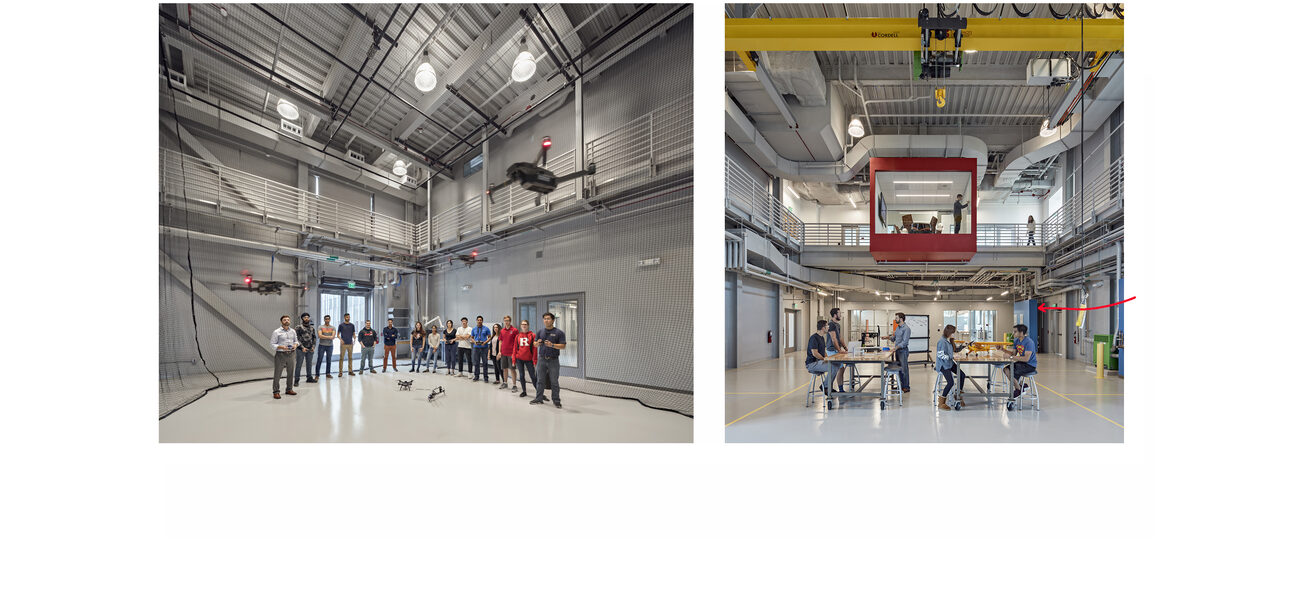

The institute encompasses a research terrace, the manufacturing pilot laboratory, and a rapid prototyping laboratory. Shared undergraduate concept labs and a microfabrication laboratory complement the institute labs. Situated across three stories, the spaces were built with transparency in mind. For example, floor-to-ceiling glass on both walls of the robotics laboratory allows indoor and outdoor passersby to see what’s happening inside. A research terrace on the building’s second level lets people view the work there but keeps them from walking through the space and disturbing tests, such as those currently being conducted for drone projects.

A full-time technical staff member was hired to manage the microfabrication laboratory, which can be used by all engineering students. A user fee structure was developed to cover costs, and Farris expects that additional equipment throughout various labs will also be subjected to user fees as the space evolves.

Pilot labs within the NJAMI provide space for research projects, including assembly, testing, and modification of materials. One problem is that new research projects often carry a hefty price tag (sometimes hundreds of thousands of dollars) to renovate or retrofit lab space.

Herrick and his team came up with the idea to create a research headwall, based on the multipurpose headwalls found in hospital rooms. They spent $50,000 each for four plug-and-play headwalls in the hope that the upfront investment would result in less expense in the long run. Each headwall has its own electrical subpanel delivering various voltages of power, compressed air, processed chilled water, local gas connections, dedicated exhaust, and local floor drains.

“I think it’s going to be a notable win for the faculty, researchers, and students,” says Schulz. “If 10 years from now we’ve had three or four users cycle through with no renovations required, that’s going to be evidence of great success.”

Building A Living Laboratory

Weeks Hall was designed so the building itself could provide teaching experiences, a vision driven by the faculty.

“Frank Moon, professor in the civil and environmental engineering department, worked with us and the contractor to install sensors in one of the main transfer beams that spans across a lecture hall and carries the load from the civil engineering labs above,” explains Herrick. “The faculty were able to monitor vibration during construction and even during occupancy, and they use that real-world data in the building to teach concepts to structural engineering students.”

In addition, the building’s partial green roof allows faculty to teach about rainwater capture and stormwater management concepts. LED lights in the building’s main area are controlled by computers, so students can learn how to program sensors and have the lights respond to any dataset, such as the number of occupants entering the building. And the building’s smart energy lab includes live feeds from energy sources around campus—such as solar panels and wind turbines—so students can investigate how their behaviors affect Rutgers as a whole.

“This is really a terrific opportunity,” says Herrick. “These are tangible things that students can relate to. Engineering is no longer theoretical; it is very real.”

By Amy Souza

For more information, read Maker Spaces Now an Essential Component of Engineering Education Facilities.

| Organization | Project Role |

|---|---|

|

SLAM

|

Architects

|