Funding for life sciences is booming, causing a space demand surge in already tight markets across North America. Companies that are ramping up production or spinning out of university labs often lease space in new or in-progress buildings but can have trouble finding the perfect fit. Commercial building inventory, both built and under construction, consists mainly of office space with systems that are incompatible with modern research missions. Outside of a few biotech-focused cities—Boston, San Francisco, and Seattle, for example—it’s hard to find a developer that understands lab space needs, so a life sciences company might hire an architect to work with developers on a redesign. Space considerations include zoning constraints, floor-to-floor heights, minimum floor plate, and electrical capacity.

“The shortest route to get up and running is to find a developer building,” says Russell Chernoff, architect, AIBC, OAA, AIA, founding principal of Chernoff Thompson Architects in Vancouver. “Our clients will often bring us a list of buildings that we examine to see if they have potential. Most commercial developers don’t understand what these companies need, though, so it’s a learning curve for them. But a life sciences–savvy developer understands that a building has to be done in a certain way to fit those tenants.”

Chernoff has been designing buildings for biotech use since the early 1990s. Currently, his firm is working with a number of private sector life sciences clients on spaces ranging from 40,000 to 500,000 sf that include labs, GMP manufacturing, and offices. He has worked within the university setting as well as with commercial developers and offers practical ways to get science space quickly in today’s market, including large-scale mid-project design shifts, adaptive renovations, fast-track developer-built science facilities, penthouse and sub-basement additions, and core relocations.

A number of considerations determine whether a site is worth pursuing:

Zoning parameters and constraints, which include floor heights, building height restrictions, and exterior appearance – Zoning calls for careful review by life sciences companies before they sign a lease, especially because some eager realtors might miss zoning details that disallow certain types of labs. Chernoff notes that industrial areas often have broader use zoning but are less desirable to companies seeking a centrally located building with access to a city center, airport, transit, and hospitals. “In the Vancouver area, we are finding that the city is very keen to encourage life sciences and this type of activity, so they have been very helpful,” says Chernoff. “But they still have rules and regulations that they have to conform with, as well. They can’t just say, ‘Okay, go ahead and build it.’”

Floor-to-floor height, 13-foot minimum – Even that amount of headroom is low, but Chernoff says it’s doable with strategic design and planning.

Floor plate, 11,000 sf minimum – If the floor plate is anything less than this, planning and building efficiency suffer.

Structural module to match lab planning modules – Ideally, a building will have a structural model that’s consistent with lab planning and spacing of benches. These lab planning modules also work well for other spaces, such as offices and meeting rooms, and can align with below-level parking. “Ideally, you want to have a module that’s as sympathetic as possible and that also generates a structural grid,” says Chernoff. “You don’t want columns sitting in the middle of benches.”

Structural system that suits labs – Many office buildings are built with either reinforced concrete or post-tensioning, in which multiple steel strands are stretched through thinner concrete slabs and fastened at the building’s ends. This offers economic and seismic benefits but limits where architects can put any penetration, even a pipe. Nothing can be done without accurate X-rays that show the steel strands’ locations. “This is not an ideal structure for a lab building, but sometimes that’s what we have to work with.”

Floor loading capacity, minimum 75 pounds psf – Office buildings usually have a floor loading capacity of only 50 pounds psf.

Systems that are suitable or alterable – Architects should examine the base HVAC system, supply air and exhaust routing and sizing, and access to sanitary drainage.

Quality of envelope – Some buildings are negatively pressurized, so architects should evaluate the building envelope. Water ingress, air control issues, and mechanical efficiency may affect lab spaces.

Planning constraints, such as core placement and building angles and curves – Core, stair, and elevator locations can affect the ability to plan efficiently. In addition, many modern structures are articulated, but Chernoff notes this can hinder efficient lab planning.

Electrical capacity, including the building’s power and backup power systems – Commercial electrical capacity is often not adequate for science activities, and backup power is undersized.

Current Case Studies

Example 1: 42,692-sf multi-tenant office building under construction in an industrial area

- Four-story building; 11,600 sf floorplate.

- 13-foot floor-to-floor height

- Mechanical system was not suitable: Minimal, office-type mechanical system with no exhaust system for fume hoods. No drainage system.

A life sciences company leased space and then approached Chernoff and his team to make it work for them. Construction was already in progress, however, so the architects had little opportunity to change the building design and instead had to work around the existing column grid to create openness, transparency, and flexible office spaces. Exhausting is one of the biggest issues Chernoff encounters. In this building, he was able to get a shaft placed in the mid-section, which brought supply air into the building.

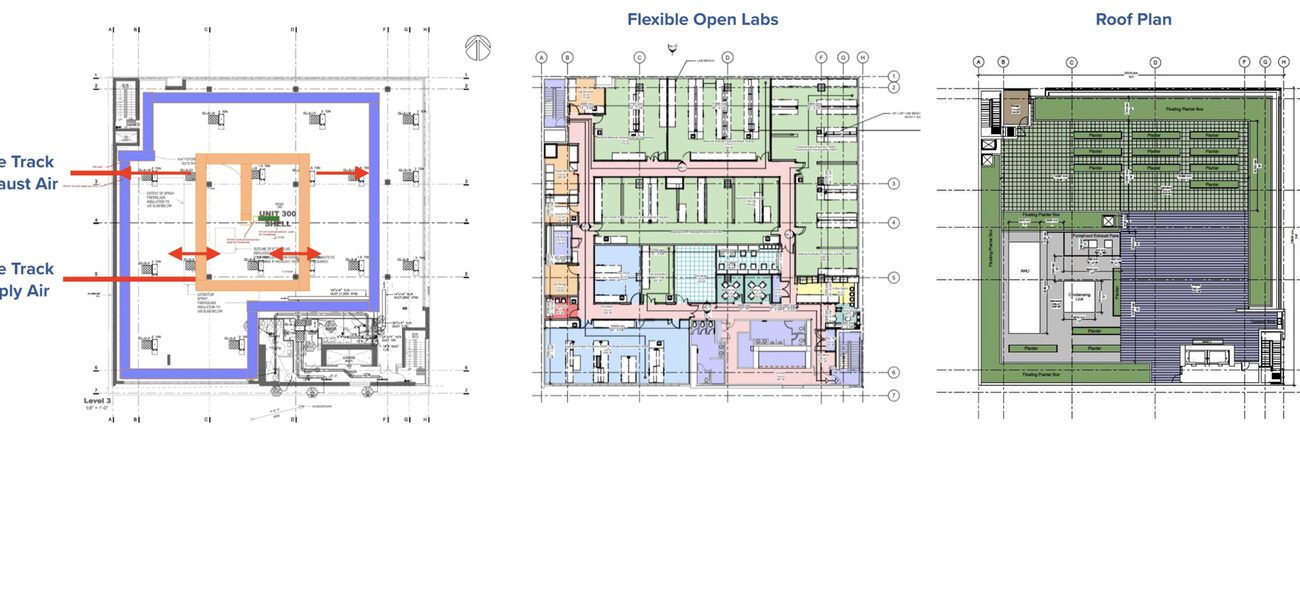

“The concept is that we have a racetrack supply and racetrack exhaust,” says Chernoff. “We create a plug-and-play environment so that, over time, we can add exhaust and put supply where it’s needed.”

Chernoff also added rooftop air handling units and a new rooftop high-plume exhaust, paying close attention to placement and exhaust emissions, because the rooftop includes outdoor gathering space. Plumbing is also designed to be plug-and-play, with distributed plumbing risers around the floor at column lines. Tight floor-to-floor heights makes it difficult to have long drainage lines running through ceiling space.

Example 2: 176,460-sf multi-tenant office building

- Eight-story building; 19,800-sf floorplate

- 12-foot-6-inch floor-to-floor height

- Post-tension concrete structure

A life sciences company leased four floors in this under-construction building, which had been built to its second or third level when Chernoff’s team came on board. Its low floor height posed a challenge, and the building had no exhaust and inadequate backup power planned. The post-tensioning created major constraints around drainage and other penetrations through the floor slab.

“If we catch it early enough, we can have builders put in core openings strategically,” says Chernoff.

In this case, Chernoff was able to get developers to add a foot to the floor-to-floor height, but only on one level. Because the building envelope was restricted by the city’s permit, that extra ceiling height got removed from a different level on which the client had leased office space. A perimeter exhaust plenum and interior racetrack supply duct allows for plug-and-play potential and minimizes the amount of ductwork running in various directions. High-plume fans were added, as well as new air handling units to provide the necessary servicing.

Example 3: Five-story office building (with plans for additional two stories later on)

- Planned 30,000-sf floor plate size

- Planned 12-foot-6-inch floor-to-floor height, except ground floor

- Post-tension concrete

- Limited access to sanitary drainage

Because the building was leased just prior to construction, Chernoff seized the opportunity to work with the developer to make major design changes.

“We had much more control in terms of the base building design,” says Chernoff.

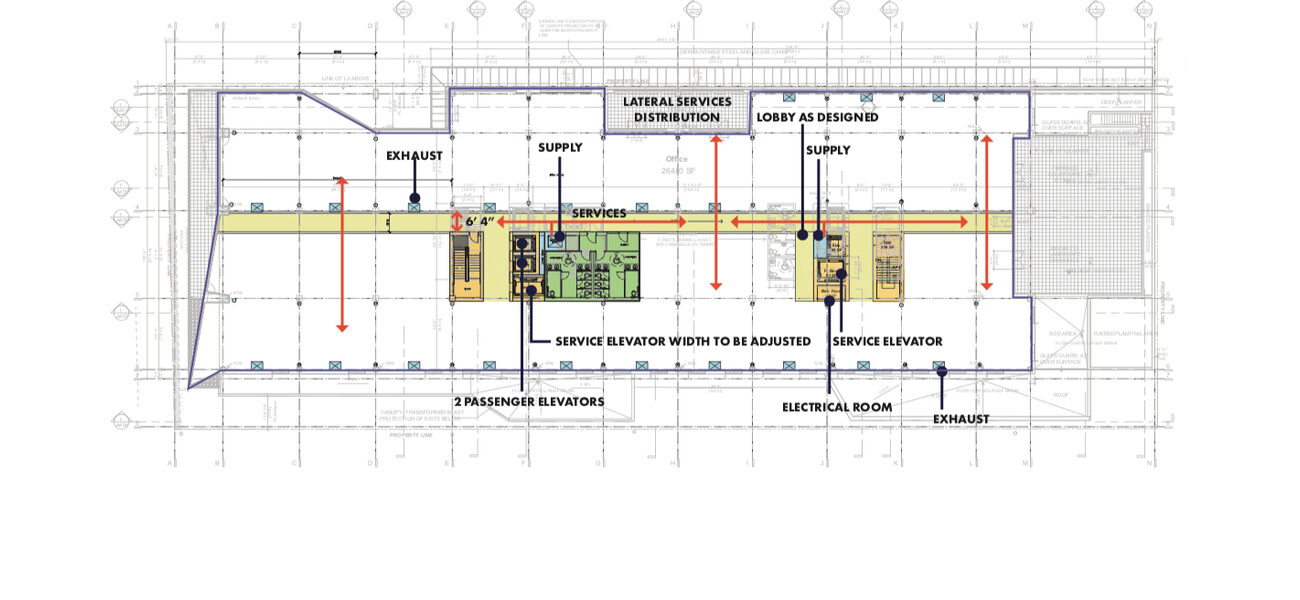

Developers were asked to shift all of the elevator and stair cores, provide distributed exhaust shafts and plumbing risers, and raise floor-to-floor heights to just under 14 feet, which required the developer to reapply for city permits based on this new configuration. Other considerations included floor-to-ceiling glazing and exterior decks.

“In a lab building, glazing to the floor limits the way in which you can plan along the exterior wall, and the efficiency of your lab planning will tend to be reduced,” says Chernoff. “Also, the city of Vancouver is keen about amenity space inside and outside, so planning had to be sympathetic to that. We don’t want anyone accessing decks through a lab.”

Mechanical systems had to be rethought, as well. For HVAC, Chernoff designed two vertical supply shafts that feed laterally into a central service corridor. Access to exhaust is now easily available with short duct runs, and distributed plumbing follows the column lines.

Example 4: Proposed design with a collaborative developer

- 22,000-sf floor plate

- 14-foot floor-to-floor height, increased for levels with decks above

The best-case scenario is for an architect to work with a developer and life sciences client from the get-go and set the criteria for a building. This allows architects to have input into all facets of design, including the building envelope, parking and loading, mechanical, planning concepts, and overall infrastructure.

“In this case, the developer was motivated,” says Chernoff. “They wanted to do a lab-enabled building. In fact, that was their prime mission with this building.”

Architects were able to establish core placement and the structural grid, as well as set the vibration criteria of 2,000 micro inches per second and floor loading of 100 pounds psf. They also designed an HVAC system with distributed shafts for exhaust and supply air coming down to a central service corridor and plug-and-play plumbing systems that are distributed around all of the columns and along the exterior wall.

The approach to planning remained flexible, because the client wants the ability to subdivide or sublease to a company compatible with its mission.

“One thing about this example is it shows we can create space that works if everybody is motivated and wants to go in the same direction,” says Chernoff.

Most developers aren’t thinking about lab space when they start a project, but they may grow more interested in this specialty as life sciences companies seek commercial leases. Architects skilled at lab design and who understand biotech needs can help bridge the gap between client and developer.

“Developers might love to do it but don’t have experience in it,” says Chernoff. “But it’s an opportunity that tickles their fancy. It’s an evolving market.”

By Amy Souza