Texas A&M University has created an integrated Engineering Medicine (EnMed) program designed to train medical school students who possess degrees in engineering, computer science, physics, and/or related career experience, to identify and solve significant healthcare problems. These physicianeers graduate in four years with both medical doctor (MD) and a unique master of engineering (M.Eng.) degree that is focused on the design and implementation of medical technologies. To fulfill this mission, Texas A&M has renovated and modernized a former bank office building into the 144,000-sf EnMed Tower, equipped with large reconfigurable learning studios, simulation spaces, flexible classrooms, multidisciplinary labs, maker spaces, and virtual anatomy labs that leverage virtual reality (VR) and augmented reality (AR) technologies. The school will graduate it first class of physicianeers on May 20.

The program is located approximately 100 miles from the main College Station campus, at the largest medical center in the world, Texas Medical Center (TMC), close to its partner, Houston Methodist hospital, which provides the clinical training for EnMed students.

EnMed students come from a wide range of engineering and technology backgrounds, including biomedical engineering, mechanical engineering, computer science, electrical engineering, nuclear engineering, aerospace engineering, civil engineering, and petroleum engineering. “Our program focuses on innovation and entrepreneurship,” says Andrew Robbins, Ph.D., research assistant professor in the EnMed Program. “To do this, we combine traditional didactic instruction with project-based learning, experiential learning, team-based learning, and other real-world type experiences.”

For example, when EnMed students take a course on respiratory physiology in the pre-clinical phase of the program, they don’t just learn about how lungs work and what lung diseases they might encounter; they also get hands-on experiences building medical devices such as mechanical ventilators. “This is very different from a traditional medical program,” explains Robbins. “They are not just sitting in a classroom all day. Sometimes they are building something in a lab, and that significantly impacts the types of facilities we need for the EnMed program.”

Making Innovation Visible

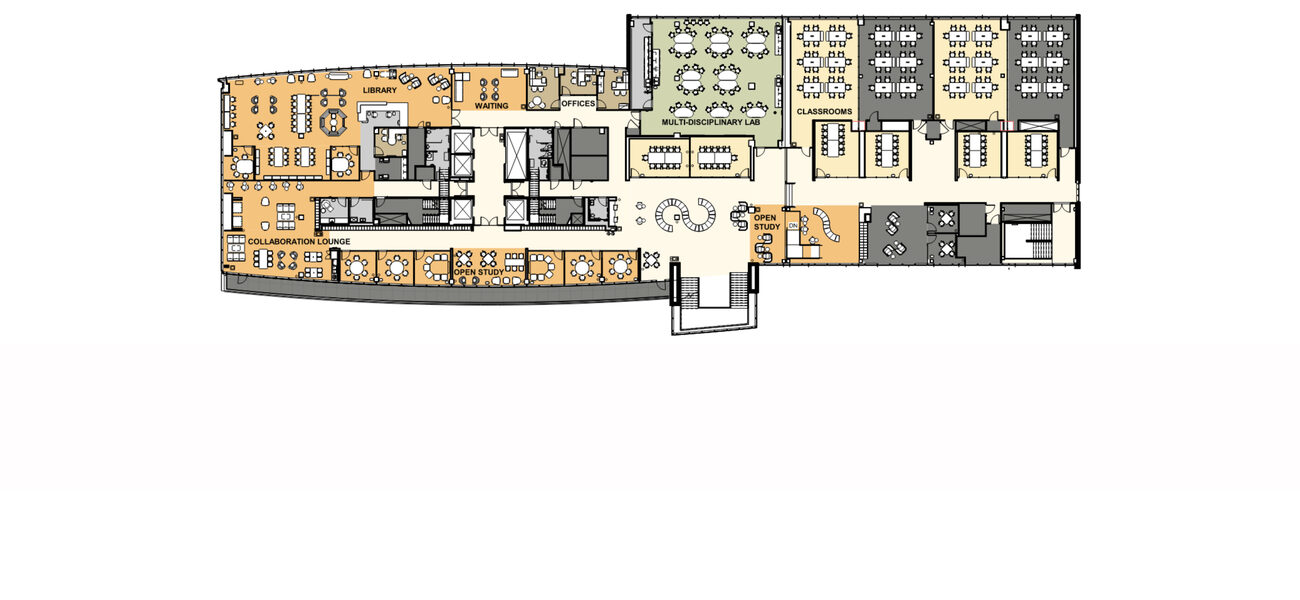

Texas A&M purchased the 17-story building in 2017. To date, the school has built out six floors, designed by Page Southerland Page, the architect of record:

- Floor 1: 9,000-sf EnMed Innovation Center (EIC) maker space

- Floor 2: classrooms and more traditional didactic spaces

- Floors 3 and 4: preclinical and clinical education spaces

- Floor 16: faculty offices

- Floor 17: event spaces and boardrooms

Floors 14 and 15 are being built out as research labs and additional faculty offices. Approximately two dozen faculty members, a dozen staff, and 150 students currently call the EnMed Tower home. Eventually, when the program is fully subscribed, there will be 200 students using the building. The university plans to use some of the floors that have not yet been built out to host technology incubator and accelerator facilities, says Robbins.

Robbins describes the EIC, where he serves as a principal investigator, as one of the only maker spaces at a U.S. medical school. “The Innovation Center is the central core of our program,” he says. “That is why we placed it on the first floor and surrounded it with glazing all along the exterior of the building, and big glass walls on the interior. The idea was to put the EIC on display so that passersby and people in our lobby can immediately see our students in the maker space working on various projects.”

Since the EnMed Tower is so far from the main campus, the conventional approach of staffing facilities with student workers represents a significant challenge for staffing the EIC. In fact, Robbins was the EIC’s only staffer until the university hired another fulltime employee to help manage the space. In the long run, the goal is to have the maker space become largely self-supporting by providing services not just internally to EnMed students, but also for external clients and collaborators. “The EIC is a space for students to work on their projects, but we also expect to provide services such as 3D printing, machining, manufacturing, and prototyping to faculty members and local collaborators,” explains Robbins. “Eventually, we hope to work more with industry, as well. Ultimately, we aim to be cost-neutral or self-sustaining, with people paying for access to specific methods or even for a chance to work with our students.”

Supporting Learning in Non-Traditional Ways

Because the EnMed Innovation Center is tailored to the unique needs of students working exclusively on projects and problems in medicine, it contains equipment and facilities beyond those normally found in a typical engineering maker space, including a cell-culture lab where students can work on tissue engineering and other biologic projects.

The classrooms on the second floor are designed for active learning, with no traditional lecture halls. The program uses a flipped classroom model where students are expected to do most of their primary learning on their own and then come to class to engage in active learning and team-based projects.

The second floor also contains a multidisciplinary lab (MDL), where students work with tissue slices (histology) and other small medical specimens, and 30 study rooms for individuals and small groups.

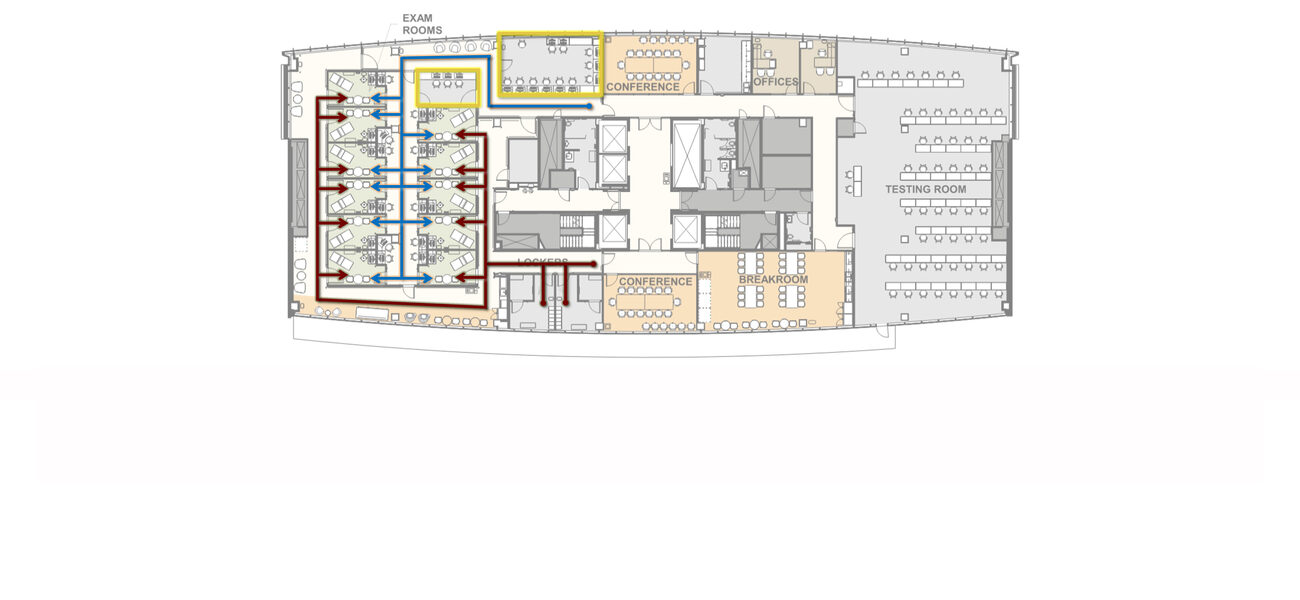

The clinical teaching spaces on the third floor include skills labs designed to simulate everything from a hospital ICU to a clinic exam room. Students are monitored remotely as they interact with actors who are trained to simulate the patient experience. In many ways, these spaces resemble those found in other medical schools, but the EnMed program provides students the opportunity to develop new technologies, bring those ideas to life in the EIC, and then try to apply the prototypes in the simulated clinical environment.

The university has formed a public-private partnership to construct two additional buildings at Texas Medical Center—a 19-story 365,000-sf student housing facility called Life Tower located next to the EnMed Tower, and a 30-story 587,000-sf general-use medical office space with some retail on the first floor and a parking garage below that is expected to be completed within a year. The cost of the entire three-building complex has been estimated at $546 million.

Staying Flexible to Adapt as Program Evolves

Because EnMed is a new program, one big challenge was to design the Engineering and Health Building without knowing all the details about the program that the building would support.

“When we were designing this facility, the EnMed program didn’t exist, so we could not know all of its needs,” recalls Robbins. “Our solution was to emphasize flexibility in the design, so that we can adapt the space as the program grows and evolves. For example, in the EIC, we specified workspaces that can be rearranged to accommodate different users. Many of the middle floors have been intentionally left empty for now to give us flexibility in terms of adding incubator spaces and research labs at a later date, or leasing out space, either to our clinical partners or perhaps to the engineering department at Texas A&M.”

Double classrooms have removable partitions in the middle to accommodate either 25 or 50 students at a time. An auditorium on the first floor and an event space on the 17th floor each can fit as many as 200 students, but Robbins reflects that it might have been a good idea to have one more intermediate-sized lecture hall or classroom for 75 to 100 students for additional flexibility.

It was also challenging to get the right stakeholders engaged. “We had to make some design changes in the middle of the project as new faculty and staff members joined the program and we gained a better understanding of their needs,” says Robbins. “At the institutional level, we had to get buy-in from the College of Medicine and the College of Engineering at Texas A&M, plus our clinical partner Houston Methodist, which has been ranked the number one hospital in Texas by U.S. News & World Report. Creating a program like this with lots of internal stakeholders in multiple colleges and departments, plus multiple external partners, takes a huge amount of time and effort. It’s important to have realistic expectations in terms of how much planning and discussion is needed to get a program like EnMed off the ground. Success depends in large part on identifying key stakeholders, getting them engaged in the process, and establishing clear lines of communication as early as possible.”

Although Houston Methodist Hospital is the program’s primary partner, Texas A&M is working on agreements with other institutions. “We want to encourage our students to collaborate with colleagues at other institutions,” says Robbins. “Getting these agreements in place is a heavy lift—it has taken years to put in place some of our partner agreements—but it’s really important to give our students the freedom to form collaborations without worrying about institutional agreements.”

Because the College of Medicine and graduate programs at the university’s College of Engineering are both accredited, the university did not need to seek a new accreditation for the EnMed program. But it did have to modify its documentation with the accrediting groups to reflect the fact that it would be offering this joint degree program and show how it would deliver two degrees in four years with an appropriate level of quality in both engineering and medicine.

Ultimately, Texas A&M aims to train and graduate a growing cohort of physicianeers who will practice medicine, observe significant medical needs, and invent new devices and tools to fulfill those needs. “We may have a few graduates who focus solely on entrepreneurship, but we envision that most of our graduates will be active practicing physicians who are inventive minded and develop new medical technologies throughout their career,” says Robbins. He observes a slight preference among EnMed students for hands-on specialties such as surgery and emergency medicine, but predicts that EnMed physicianeers will pursue many different health specialties.

By Aaron Dalton