Many Veterinary Diagnostic Laboratories (VDLs) face operational challenges stemming from their aging facilities, which can jeopardize the biosafety and biosecurity of their environment and hinder testing efficacy and turnaround times. Key strategies to modernizing these facilities include evaluating and improving sample receiving protocols and personnel/material circulation, as well as spatial planning and process optimization of the necropsy operation. These steps are aimed at improving the efficacy and efficiency of diagnostic services; achieving necessary biosecurity and biosafety standards; and attaining accreditation from the American Association of Veterinary Laboratory Diagnosticians and the National Animal Health Laboratory Network.

According to Jim Chen, senior lab planner at Perkins&Will in Houston, state-level VDL’s started to emerge about 70 years ago thanks to strong demand from the livestock industry, and have since evolved to be the front line of animal disease surveillance, including zoonotic diseases. “VDLs serve an important role in controlling disease outbreaks that can negatively impact the food industry and ultimately public health,” says Chen, who has been involved in redesigning a wide variety of VDLs across the country.

Biosecurity and Biosafety Considerations

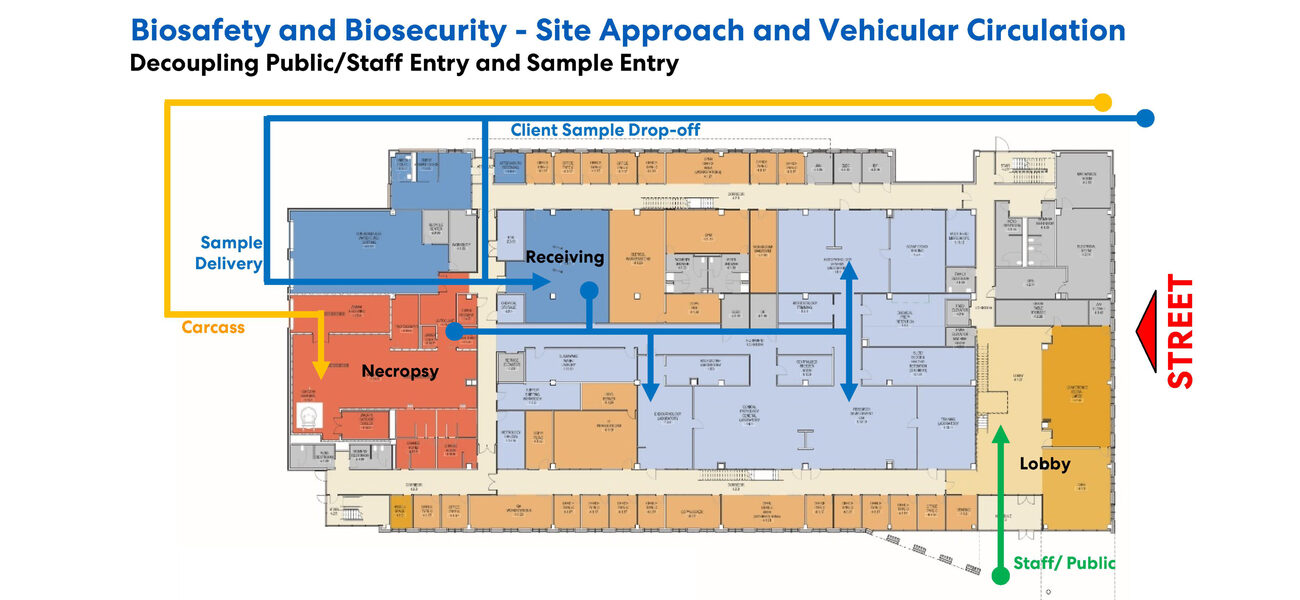

Many older VDLs collocate their front entry with the necropsy dock or share a building entrance where both staff and the public enter through the same area where samples are received. Both scenarios present biosecurity and biosafety risks, with potentially pathogenic samples kept in semi-public spaces and moved through clerical areas before reaching the lab.

Chen recommends analyzing the approaches to the facility and vehicular circulation patterns and considering a variety of solutions including:

- Decoupling the Public/Staff Entry from the Sample Entry – The main entry of the Texas A&M Veterinary Medical Diagnostic Laboratory is located at the opposite side of the facility from where test samples are received, effectively separating the personnel entry from receiving of biohazardous material. “It was important for this facility to maintain a high-profile public main entry, since they serve as the flagship facility within the Texas veterinary diagnostic network, yet their clients dropping off samples should not feel that their reception is secondary,” says Chen. He adds that the entrances do not need to be at opposite ends of a facility as long as they are physically separated.

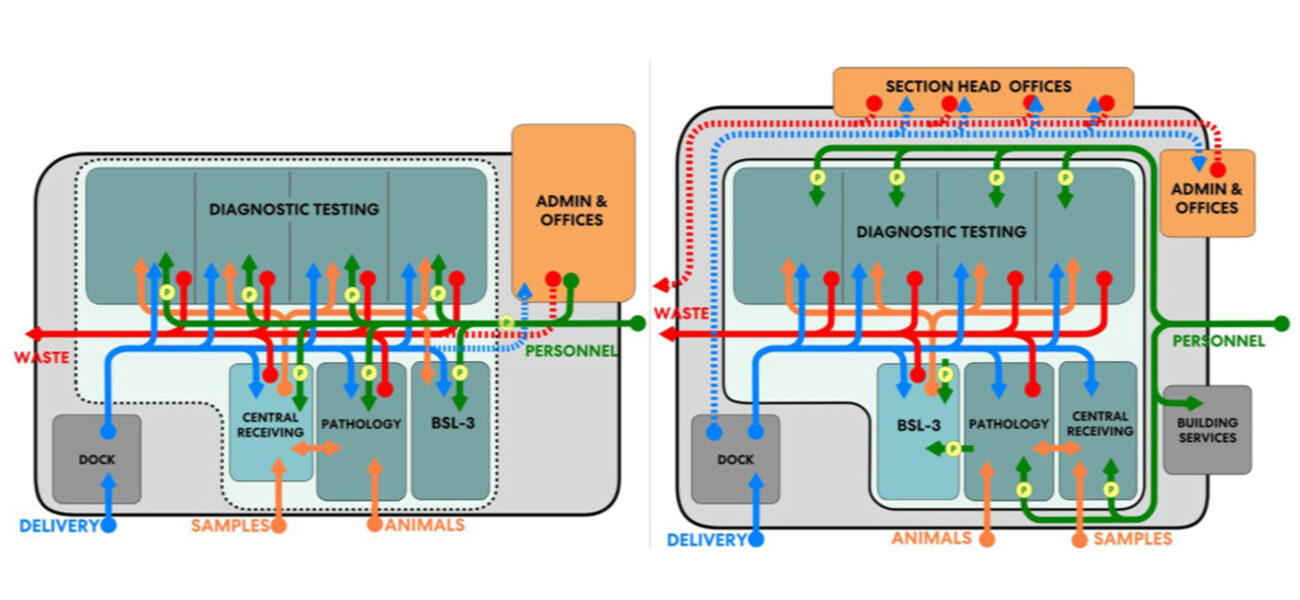

Distinguishing Clean from Dirty Vehicular Access Points – Ideally, the VDL will have an entirely separate “clean” vehicular access for staff, visitors, parcel services, municipal waste pickup, and maintenance; and a separate “dirty” vehicular access for necropsy delivery and for clients walking in or driving through to drop off samples. This separation of vehicular access eliminates cross-contamination of site traffic.

The dedicated site exit may be integrated with an additional vehicular decontamination facility to elevate biosafety for the client. The Turlock North Valley Lab in California provides a covered truck and trailer wash station on the way out of the site to facilitate vehicle decontamination as desired or required by situational protocol. The standalone structure includes high-pressure hot water and disinfecting detergent wash and sits over a recessed pit which contains the washdown.

- Separating Laboratory Circulation from Office Circulation – Many older VDLs utilize double-loaded corridors that force non-laboratory circulation to be shared with laboratory staff moving biohazardous samples and waste, introducing obvious biosafety risks. Ideally the workflow for laboratory staff, samples, materials/paperwork, and waste should be completely distinct from the office and non-laboratory circulation, which may include administrative staff, visitors/students, and facility maintenance.

Necropsy Planning

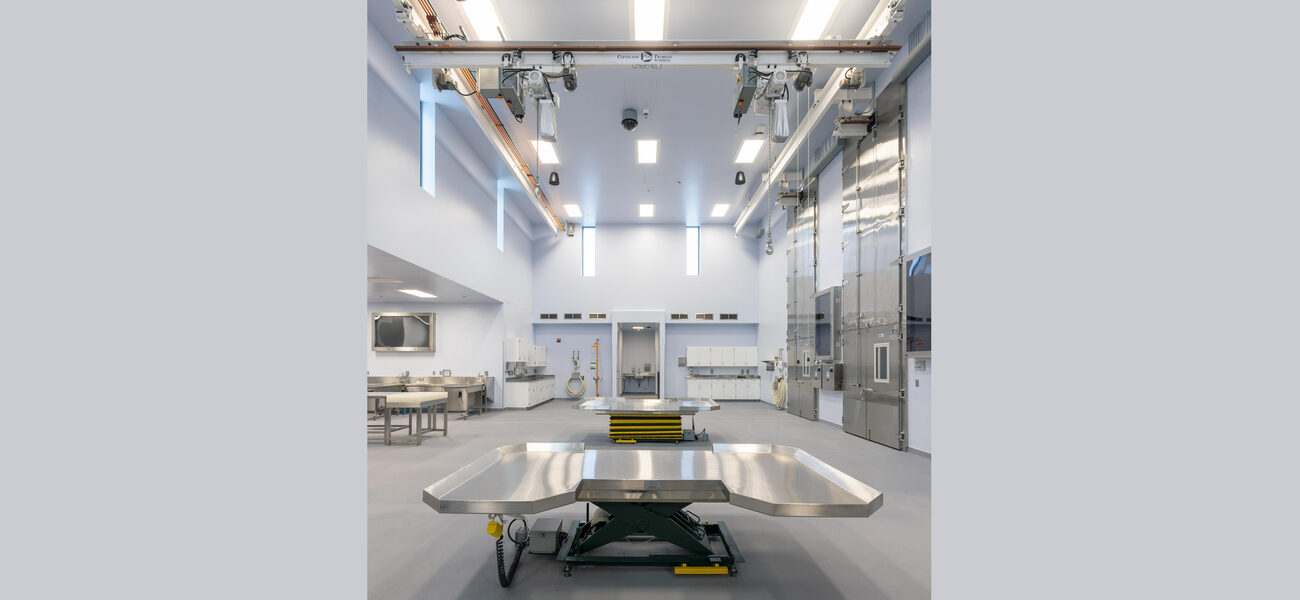

Most full service VDLs include large animal necropsies, which can make these some of the most expensive facilities to build and operate. The appropriate carcass conveyance system and disposal method may be identified through caseload analysis and budget considerations.

- Monorail Systems – Akin to how a factory assembly line operates, monorail systems convey large carcasses along a prescribed path using motorized trollies to carry loads along overhead rails. According to Chen, the keys to a well-planned monorail system are prioritizing the switch configuration to the most frequently used pathways, minimizing reliance on directional switches and directional changes along the rails.

- Bridge Crane Systems – These systems typically are more costly than monorail systems but facilitate greater operational flexibility within the necropsy space. Bridge crane systems consist of two elevated runways running parallel along the length of the crane, and moveable girder beams that support the load-carrying trolley. This enables pick-up and unloading of carcasses anywhere within the bridge crane footprint, maximizing the floorspace for necropsies and avoiding sequential limitations associated with monorail configurations.

Carcass Disposal Methods:

Chen recommends approaching each project with a feasibility study to determine which disposal method is most appropriate, including a review of local regulatory and permitting requirements, the municipal sewage treatment tolerances, and the desire for BSL-3 necropsy capability.

- Off-Site Rendering –When cost or local jurisdiction prohibit onsite disposal, VDLs may be limited to this disposal method. It is imperative that the carcass cold storage area includes space for extra storage in case of delays in rendering pick up. Planning consideration includes coordination of rendering pickup mechanisms with dock design, separation of wash down from storm water drainage, and implementation of visual barrier from neighboring facilities to ensure privacy of operation.

- On-site Incineration – There is a wide variety of configurations to consider for on-site incineration including above-ground and in-ground systems.

Above-ground vertical charging systems receive batch loads directly into the primary chamber, place all equipment at grade, and are appropriate for low caseloads. They are cost effective to install but may pose ergonomic challenges in large carcass loading.

Above-ground horizontal charging may necessitate an ash pit and additional mechanical loading components, such as horizontal ram and cart lift. This system faces similar challenges in large carcass loading.

In-ground horizontal charging systems require a deep basement and additional horizontal ram mechanisms but facilitate loading better than above-ground systems, says Chen.

In-ground vertical charging systems are most accommodating of large carcass loading but require a deep basement and interlocking horizontal fire doors. Heat and exhaust can be more difficult to contain with continuous loading, with direct charging opening into the chamber.

- Tissue Digestion – Caustic digesters utilize alkaline hydrolysis to break down tissue, and then apply heat and pressure to dissolve and sterilize carcass waste in a caustic solution such as sodium or potassium hydroxide. Caustic digesters require removal and disposal of bones and other solids after the cycle.

Thermal digesters, on the other hand, primarily utilize agitation and heat to break down tissue with minimal water and caustic chemicals.

Tissue digestion does not require the permitting process of incineration, but acceptance by the municipal sewage treatment plant must be thoroughly vetted.

BSL-3 Planning Considerations

BSL-3 facilities may require specific enhancements and building system implementations based on risk assessment of the target diagnostic and/or research capabilities, including HEPA filtration, liquid effluent decontamination systems, and operational redundancy. The effluent treatment solutions can be locally or centrally located, and can use either chemicals or heat. Localized systems, while cost effective, are limited in application. Centralized thermal cook tanks, while the most effective high-capacity system, are cost prohibitive in most applications.

Planning for the Future

“Since methodologies and the technologies involved in disease testing are constantly evolving, new VDLs should be designed with the adaptability to accommodate evolving trends,” says Chen. He adds that there is a growing demand for molecular diagnostics, real-time polymerase chain reaction (PCR) testing, and next-generation sequencing. He recommends a flexible design that includes moveable casework and equipment, and lab planning concepts that that adapt to fluctuating test demands and allow for expansion when seasonal testing surges occur. Chen also predicts that high throughput and high-fidelity diagnostic testing equipment will become more prevalent in VDLs, and emphasizes the importance of adaptable planning for future implementation of additional utilities.

By Amy Cammell