A new approach to the design of diagnostic labs in resource-constrained settings reduces risk and improves outcomes while accelerating the project timeline and lowering costs. The approach is based on the concept of One Prototype, which uses similar design modules as a starting point for each lab facility, whether new construction or renovation, no matter what the scale.

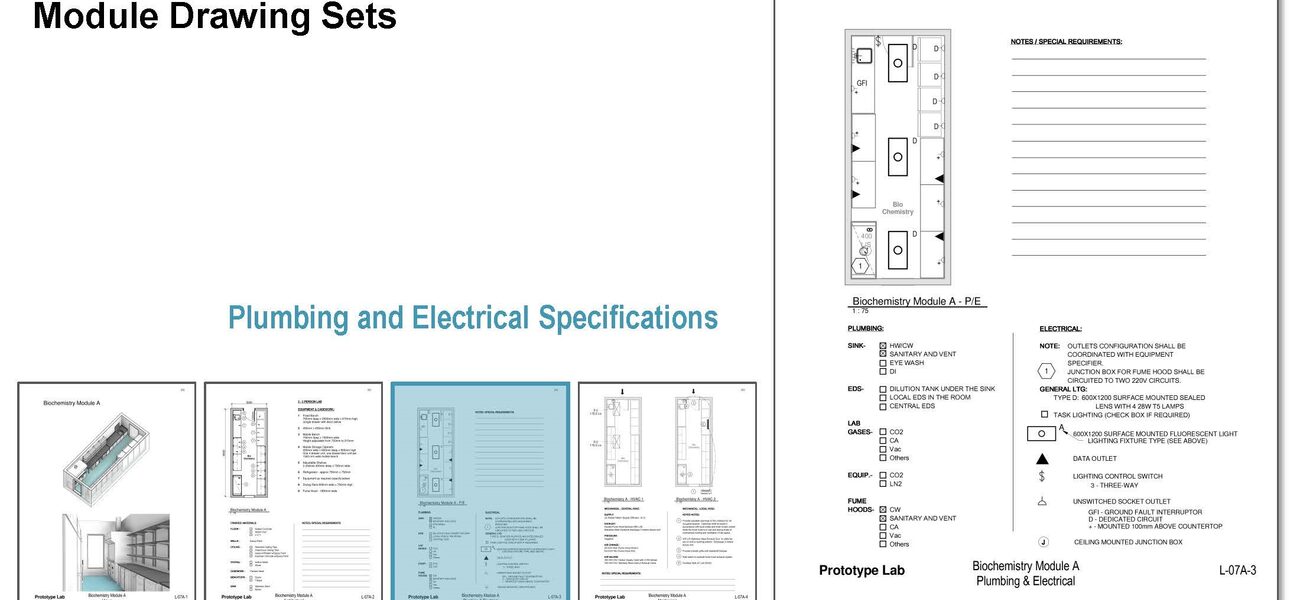

One Prototype includes a catalogue of floor plans for the three components of the typical diagnostic lab building—lab, support, and amenity spaces—complete with drawing sets that list plumbing, electrical, and mechanical specifications, as well as equipment and casework options. The drawings have been tailored to ensure lab performance given the limitations likely present in emerging nations.

“One Prototype is a design tool that can establish a consistent and repeatable platform to improve testing outcomes and promote biosafety,” says architect Warren Hendrickson, vice president and director of education, science, and technology at HDR.

Replacing the customary process of bespoke lab design, One Prototype has been created to serve geographic areas that face challenges like low funding levels, brown power, and spotty availability of standard materials, repair know-how, and spare parts, explains William Arndt, Ph.D., a microbiologist and systems analyst with Sandia National Laboratories International Biological and Chemical Threat Reduction Program.

The One Prototype concept, developed by Sandia and HDR, with support from the U.S. Defense Threat Reduction Agency, is an outgrowth of One Health, a movement initiated by the global infectious disease community to address the links among human, animal, and environmental health. The international initiative seeks to expand collaborations and communications in all aspects of health care.

“Traditionally, these laboratory groups didn’t talk to each other that much, but there is a lot of information that, if relayed correctly, could really help in the fight against infectious diseases,” says Arndt. “Close to 70 percent of the diseases that have emerged in the past are zoonotic, affecting both animals and humans. People who play a role within the diagnostic lab need to work together for the best impact.”

Risk-Based Design Decisions

One Prototype draws on the lessons learned from containment labs overseas, focusing on major release pathways.

“The overall design process is driven by risk-based decision-making to inform and direct the facility design,” says Arndt. “The facility conducts a biosafety and biosecurity assessment. We ask what agents they are working with and what activities are associated with their testing. Then we provide guidance on what mitigation measures are needed to address the risk.”

Arndt points out that biosafety and biosecurity risks differ significantly between diagnostic and research laboratories.

“Diagnostic labs are our first line of defense for emerging threats and diseases,” he says. “The clinical samples they deal with are far less concentrated than those used in the research lab, which lowers the risks of accidental exposure or release.”

Perhaps surprising to architects and scientists in more specialized environments, One Prototype diagnostic labs are designed to operate safely without heavy-duty mechanical ventilation.

“Sophisticated HVAC systems don’t like power surges,” Arndt points out. “These facilities often leverage natural ventilation strategies to drive directional air flow.”

For containment, a primary device like a biosafety cabinet protects the staff working with the agent and keeps the agent or operator from becoming contaminated.

“In a low-resource setting, the biosafety cabinet is the primary containment barrier,” he notes.

One Prototype also reinforces good lab practices in regions where they may not be commonly deployed. For example, the laboratory plans promote locating the biosafety cabinet as far from the door as possible to minimize traffic and air disruptions while in use. Similarly, sinks are placed closest to the lab entrance, to encourage hand-washing and avoid the subsequent spread of bacteria.

“This may sound simple, but it’s a huge improvement based on some of the labs we’ve been to,” says Hendrickson. “The One Prototype process focuses on helping our partners think through all the steps necessary to make good design decisions managing their risk.”

88 Different Modules

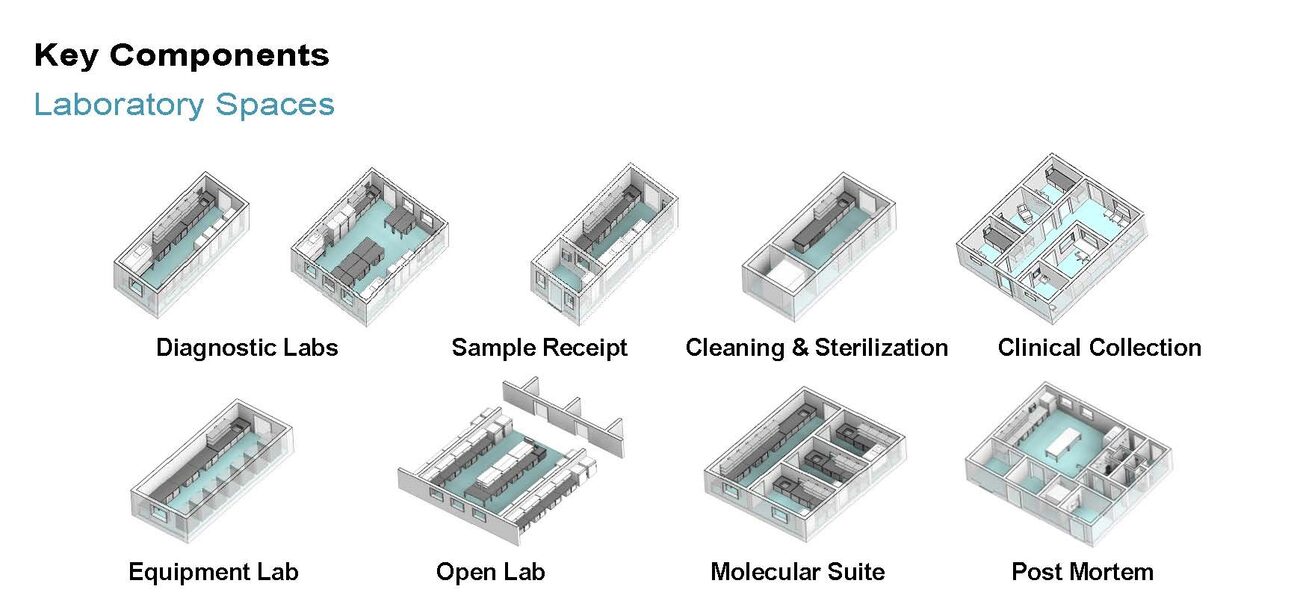

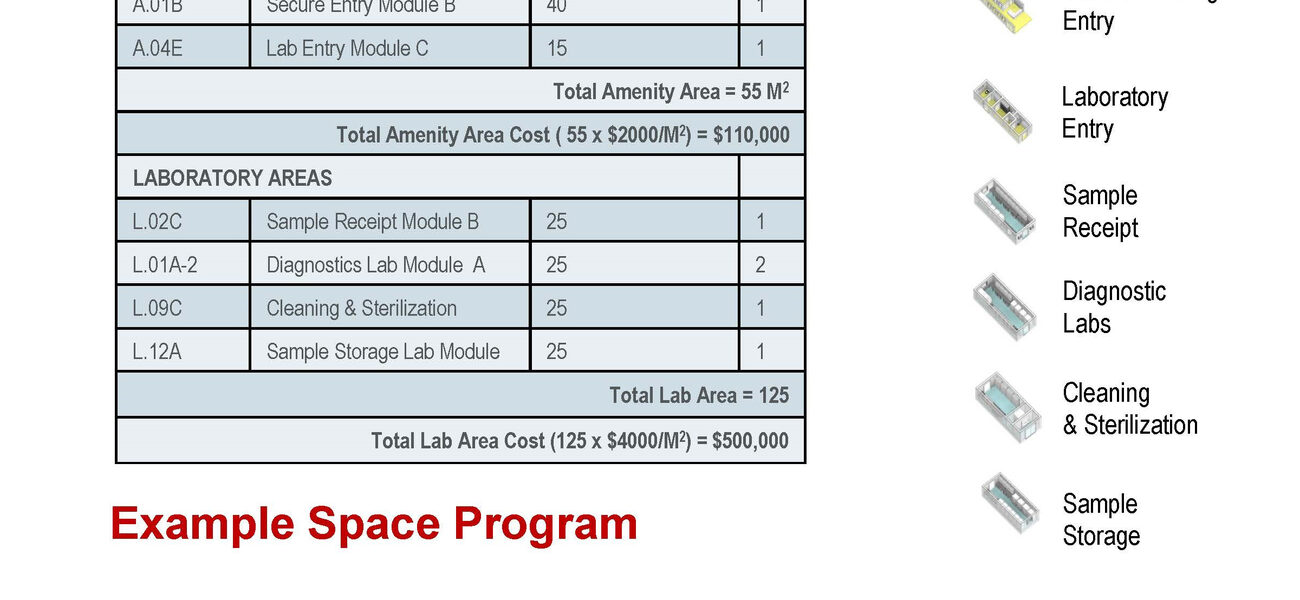

One Prototype divides the overall facility into three primary components—labs, support spaces, and amenity spaces. The lab component encompasses diagnostic labs, sample receipt, cleaning and sterilization, clinical collection, equipment lab, open lab, molecular suite, and post mortem. Support spaces house electrical and plumbing support systems and loading and storage. The amenity category includes secure entry, washroom, staff office, lab entry, multifunction room, and break room.

Taking into account the requirements for the specific activities performed in each space, the catalogue currently presents a total of 88 possible modules, more than half of which are dedicated to the lab components. The prototype streamlines design by keeping to a planning model of approximately 11 by 25 feet for all labs, making it easy to add on extra modules for larger facilities. The predesigned modules also streamline the roles of architects, and mechanical, electrical, and plumbing engineers, allowing them to focus on issues that are unique to the specific lab much earlier than in a traditional design process.

In addition to the significant A&E cost savings, the modular approach assists contractors by pinpointing where to put up walls and install service connections, and simplifies duties for operations and maintenance personnel.

Each module is described in a drawing set that lists options for the equipment and casework, finishes and materials, and services required for the space to function appropriately.

“It is embedded in the module what the flooring material or the bench should be for that particular module,” says Hendrickson. “We are not starting with a blank sheet of paper.”

“We help our partners find the right Lego® blocks to add to the full design,” adds Arndt.

The drawings also include a 3D visualization of the completed space, “a very effective communications tool to allow scientists to understand the design,” says Arndt. “When they see the different ways the lab would look, they can envision what it would be like working with their particular agent and activity in that space. It is also helpful in planning adjacencies and circulation.”

Cost Calculation Spreadsheet

An integral part of the One Prototype toolkit is the cost calculation spreadsheet, which the planning team presents to its partners after a preliminary discussion of their needs, providing a rough, order-of-magnitude idea of the facility cost. Done so early in the design process, this step is a major factor in compressing the timeline.

The spreadsheet is populated with the typical building cost for each of the 88 modules, followed by costs for equipment and casework and a range of furniture. As options and quantities are selected, the costs are recalculated in real time.

“A subtle detail is that, in every country, we work with the local contacts to find locally sourceable materials,” Hendrickson says. Some items, like biosafety cabinets, might have to be purchased from abroad, incurring shipping charges and taxes. “We adjust costs based on local sensitivities and constantly challenge the numbers.”

The example of a district lab of 1,938 sf (180 square meters) illustrates the way the spreadsheet efficiently guides the planning team partners through their decision-making. The facility’s space program breaks down into approximately 70 percent lab (sample receipt, diagnostic labs, cleaning and sterilization, and sample storage) and 30 percent amenity space (secure entry and lab entry). Based on average costs per square meter for each type of space, the area cost is $610,000. Next is the selection of equipment and casework necessary for the four different lab modules from a predetermined list of variations, which adds $307,000. The final choices relate to furniture—from desk chairs to sinks—and quantities, amounting to $6,700. The overall total for the facility comes to $923,000.

“By the end of the meeting, we have the total cost of all the modules, so we know where we are,” says Hendrickson. “And now comes the debate—is the cost per square meter right, or is more or less equipment needed? The ability to mine the data gives us a good place to start.”

With the biosafety and biosecurity requirements determined, the automated calculations free up time and attention to focus on other aspects of facility performance, such as personnel training, SOP development, flow analysis and adjacencies, operation and maintenance plans, and site integration.

“We can drill down into issues that will really have an impact, such as science-based relationships in the lab or how samples get to the lab and waste is removed, and show our partners industry best practices,” says Hendrickson.

Condensed Timeline

Arndt and Hendrickson emphasize that while the catalogue and spreadsheet settle questions early in the project, it is the comprehensiveness of the One Prototype process that represents the most significant contribution to high lab performance.

The process engages a long list of stakeholders: scientific staff, facility administrators, bio-risk management advisor, operations and maintenance staff, funders, regulatory authorities, community representatives, peer reviewers, architects, engineers, and local architects. Despite these multiple sources of input, the planning timeline calls for a series of just three in-person meetings with partners, each about a week long and three weeks apart.

“We’ve found that if you rush decisions, you don’t get as good an outcome,” says Hendrickson.

The first meeting is devoted to issues relating to space, equipment, people, and tests. The second addresses flows, preliminary layouts, and finishes. At the last meeting, plans, details, and costs are finalized.

“Each lab will be different based on the requirements to function for its end users,” says Arndt. “The final design depends on agents and activities. These will be different for every lab around the world, but they all have some similarities. One Prototype is not meant to standardize them, but rather to educate users on best practices, safety and security, and the contamination of samples and the environment,” he concludes.

By Nicole Zaro Stahl

| Organization |

|---|

|

HDR, Inc.

|