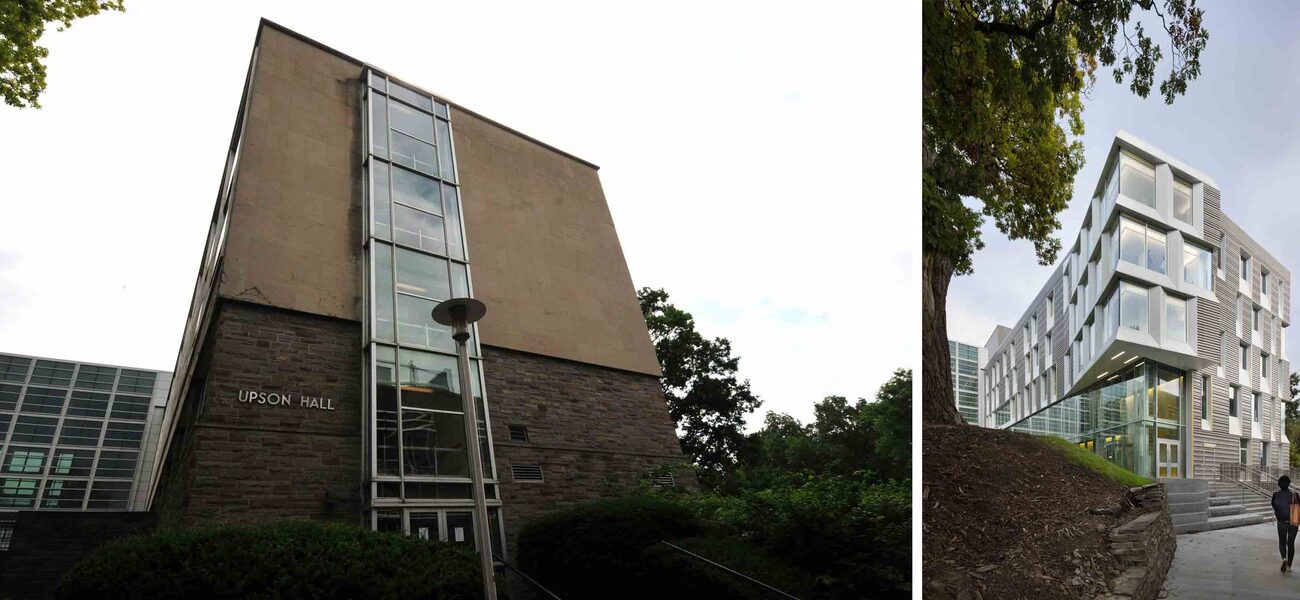

The College of Engineering, one of 15 colleges and schools at Cornell University, has 21 percent of the undergraduate population, 32 percent of the graduate population, and 10 percent of the square footage of the campus. As part of the college master plan, Upson Hall, originally built in the 1950s, and one of the largest buildings on the engineering quad, was in line for modernization. The plan called for improving energy efficiency, providing student and faculty collaborative space, and creating wet, hybrid, nano-, bio-, and chemical engineering labs. Since the building is well-located and structurally sound, with good floor-to-floor heights for labs, the decision was to renovate the existing structure, rather than undertake new construction. The project, a complete gut and renovation of the 160,000-gsf building, scheduled in two approximately year-long phases, was completed in August 2017.

The scope of the work—designed by the architecture team of LTL and Perkins+Will, and constructed by The Pike Company contractors—included upgrading the exterior façade, changing out the windows and entries, and adding about 1,000 gsf, including bump-outs on the fourth and fifth floors. The building now has up-to-date engineering research and teaching space, and new nano- and biotechnology lab space; and it meets current safety, accessibility, and sustainability requirements, all in a flexible, modular layout to accommodate future growth. “The building was not able to manage our current research. We had the chance to reimagine the space to allow us to cluster research areas for greater efficiency and interdisciplinary collaboration,” says Erin Mulrooney, associate dean for administration for Cornell Engineering. The $74.2 million project budget included enabling costs, such as a server room relocation, relocation and build-out of the computer systems lab, temporary student team locations, tank removals, and utility relocations.

The renovation project is part of a college master plan that anticipates growth and the need for ongoing restoration and building projects. It is based on 10 design goals conceived by the architect and the administration: flexibility, modularity, collaboration, learning, sustainability, history, identity, vision, and visibility. “We wanted the labs to be flexible to enable change over time, to allow for multiple users, and encourage sharing of resources. We used modular standards to create efficient and equalized spaces and to enable more effective changes in the future,” says Mulrooney. The master plan is also intended to help make sure future renovations on the engineering quad and elsewhere have a similar look. “While this project was under construction, we completed an update to our college master plan to guide the next few projects that are upcoming,” says Mulrooney.

The Challenges of Phased Construction

Phase 1 of the Upson Hall project involved the building’s top three floors, and took place while the bottom three floors were occupied. This phase comprised all of the major infrastructure, including installing new mechanical systems and fabricating new windows. The second phase involved the lower three floors, while the top floors were in use. The decision for phased construction was based primarily on space considerations. At the start of renovations, Upson Hall’s upper floors had vacant space because a non-engineering program relocated elsewhere on campus. It seemed likely that the upheaval would be minimal.

However, one of the most significant challenges was the difficulty of planning for the vertical components of phased construction. “One of the things we really underestimated was the impact of the construction on the floors that would be occupied. You need to think about that. It can be done but you really need to prepare everybody for the impact,” says Tom King, director of facilities for Cornell Engineering.

Even rooms not scheduled for use during construction were impacted by work in the building. For instance, while the upper floors were occupied, temporary heating lines had to be run down through the ceilings of the floors below. In some cases, holes needed to be cut in the flooring, and work areas tented off to minimize dust and sound. There was work in the basement, and ductwork had to be run to upper floors. “Very few rooms were excluded from the process,” says King. In addition, building codes required boarding up the lower floor windows in rooms adjacent to construction areas, as a safety measure, but it darkened those rooms. “We were able to put a little awning on those and get a little daylight in there for people, but it certainly was not the best scenario,” says King.

They did consider doing the renovation one wing at a time (vertically), rather than by floor (horizontally), but city authorities were concerned about egress, and whether stairwells would be accessible during construction. “I think that now that we have gone through it, if we had to spend a couple hundred thousand dollars on a temporary stairwell, it probably would have been worth it,” says King.

Themed Labs and Shared Space

The decision to keep the structural grid of the building helped dictate placement of the research labs. “The south wing is 35 feet wide, and the west wing is 28 feet wide. The research labs weren’t going to go in the smaller-width floor plate,” says King. Teaching and the computational areas are in the west wing, and the mechanical labs are in the south wing. “We didn’t have dedicated floors for any particular research type,” says King. The heavy equipment for the mechanical engineering teaching labs, such as wind tunnels and flumes for fluid dynamics experiments, are located on the lower floors. Chemical and hybrid labs are mixed on the intermediate floors. Robotics is on the fifth floor, so it is close to Rhodes Hall which houses the computer systems lab.

Upson Hall now has about 30,000 sf of research labs, 15,000 sf of student team laboratory spaces, and just over 9,000 sf of teaching lab space. The interior space is reconfigured, going from the original two corridors on a floor plate, to one corridor per floor, which allows windows for most offices and research labs. Building services are located in the walls adjacent to the end of each module run. “You can move walls within the module layout and change the size of the modules on the floors, without interrupting a lot of the building services,” says King. “We didn’t do very expensive things but we did some practical things that will allow us to have some flexibility in the future.”

Offices to support graduate students are now located near the labs. Every three faculty offices share a conference room they can reserve for meetings and working with students. These rooms also have AV systems, including distance learning capabilities. When the building opened, those rooms didn’t have locks, but now some do. “Initially, students were going in there in the evenings and setting up pizza parties. Faculty would come in for their 8 a.m. meeting and they wouldn’t be able to get into their shared meeting space. So, we had to put some locks on those doors that only the faculty have keys to,” says King.

Among the building’s various collaboration spaces, the most heavily used are student lounges in the bump-out sections, where the two wings meet on each upper floor. Students use these spaces for study groups or informal meetings. Cutting a hole in the floor allowed space for an interconnecting stair near that lounge, so people can circulate easily.

Sustainability Achievements

Upson Hall meets planned goals for sustainability, accessibility, and energy efficiency, and is on track for LEED Platinum certification. There is new LED lighting throughout the building, and new windows and better insulation help improve heating efficiency. Although energy cost data for the first year is not in yet, new plumbing fixtures are expected to reduce water use by about 40 percent, and upgraded digital control systems with occupancy sensors are expected to reduce energy consumption by 65 percent. The project takes advantage of the district energy system at Cornell, and includes a lake-source cooling system, which pulls cold water from Cayuga Lake.

Windows in the building are strategically sized and placed according to the function of the room they are in, which gives the façade a unique look. The windows are placed with the goal of meeting energy efficiency and cost goals. “The architects spent a lot of time thinking about what is on the other side of the wall, and how much natural light does that space need, because windows are obviously a penalty for the insulation. Office, classrooms, lounges, and labs all have a different window modularity frequency. I think it looks great from a design perspective, but it also is very functional, and has a performance and a sustainability aspect for the building,” says King.

By Mary Beth Rohde