Mass timber construction is widely lauded for its sustainability benefits, including wood’s natural carbon sequestration, lower embodied energy footprint, lighter weight compared to steel or concrete, and essential renewability. But does it pay off in terms of a university’s performance standards and cost concerns when embarking on a project as ambitious as Oregon State University’s Jen-Hsun and Lori Mills Huang Collaborative Innovation Complex, a $213 million, 143,000-sf facility dedicated to advanced programs in artificial intelligence, robotics, energy, and materials science? Scott Ashford, OSU’s dean of the College of Engineering, and Libby Ramirez, the university’s resident architect, argue that with careful strategy and an eye toward the data, the answer is “yes.”

Like many similar buildings being considered for development on campuses worldwide, the Huang Complex in Corvallis, Ore., seeks to emphasize sustainability, flexibility, and technological advancement in a collaborative academic space. Unlike traditional academic buildings that serve a single department or college, this facility is designed to bring together experts from various fields, including engineering, oceanography, forestry, and robotics.

With sustainability being a key pillar of the Huang Complex’s development, the university engaged ZGF as the project’s lead architects and designers. The resulting proposal was a mass timber building clad in brick, that adhered to the stringent regulations of the community’s historic district.

“We didn’t go into this project at the beginning saying that we wanted to do a mass timber lab building,” says Ramirez. “ZGF did this great analysis for us, showing if we had gone all concrete, hybrid, or all mass timber, the reduction that we would get (from mass timber) would be 108% in carbon emissions.” In addition, the school’s College of Forestry seconded ZGF’s push for traceable and responsible wood sourcing. “The dean for the College of Forestry came forward and said, ‘We’re doing some sustainable wood harvesting in the college forest. Can we be part of the procurement process?’ As a result, we will be able to trace some of the actual trees that came out of the forest and track them all the way to one of the panels that is in the lobby.”

The building serves as a convergence point for multiple disciplines. “It’s about collaboration and working with deans from other colleges,” says Ashford. “It takes a lot of trust to raise money for a building like this.” Despite the enthusiasm surrounding the project, constructing a high-tech facility using mass timber posed several challenges. “When we started talking about mass timber, the faculty were initially very concerned,” says Ashford. “This was going to be the home of the first cleanroom in the U.S. that was a mass timber structure.”

The suitability of mass timber for a cleanroom environment required rigorous testing and analysis. Could a wood-based building manage the considerable heat associated with supercomputers and other ventilation needs? OSU’s College of Forestry stepped up once again, collaborating with the College of Engineering and with Freres Engineered Wood to conduct groundbreaking research on mass plywood panel (MPP) applications. “We had our engineer do vibration analysis for the entirely mass timber structure,” says Ashford. “It turns out that it actually performed better than all-concrete or hybrid. So we’re getting better vibration performance for the sensitive equipment that we have in the building.”

“We got the testing back and handed it over to KPFF, the project engineers, and everything was copacetic,” says Ramirez.

The facility’s environmental impact is further reduced through innovative energy solutions. A supercomputer heat recovery system will contribute to heating and cooling nearly 500,000 sf of surrounding campus buildings through a four-pipe distribution loop. Additionally, a cascading air strategy within the lab facilities optimizes ventilation efficiency, while a rooftop photovoltaic array contributes to renewable energy production.

A Hub for Collaboration and Excellence

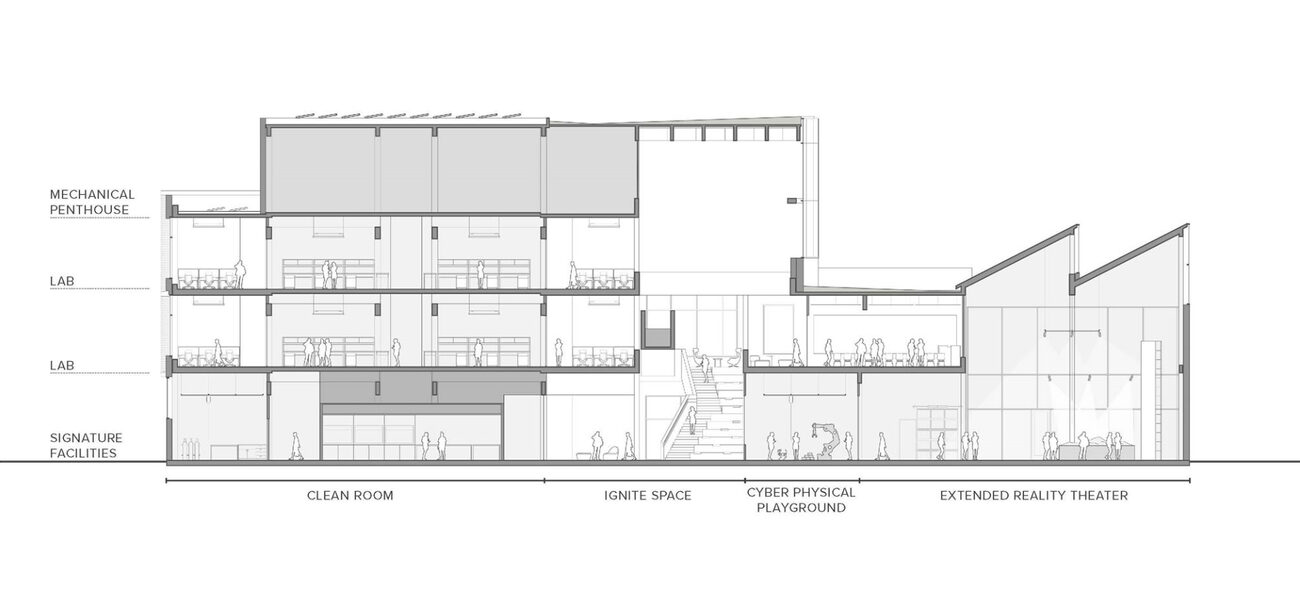

The Huangs donated funding for one of the fastest supercomputers in higher education to the complex. This high-performance computing system will play a pivotal role in advancing AI, data science, clean energy, climate research, robotics, and biotechnology. The building also boasts specialized research spaces, including a cyber-physical playground, an extended reality theater, a seven-bay-and-chaise cleanroom, and various modular lab facilities. These unique features set the complex apart from existing facilities on campus, ensuring that researchers have access to resources that do not currently exist elsewhere at OSU. The decision-making process involved balancing faculty needs, budget constraints, and future flexibility. With a focus on adaptability, the building’s design includes modular experimental labs, computational spaces, and hoteling-style office spaces to accommodate researchers on a temporary basis.

OSU’s nationally recognized programs—such as its top-ranked forestry program and world-leading programs in robotics and in oceanography—will have a strong presence in the complex.

A Strategic Vision for the Future

The Huang Complex is more than just a building; it is a catalyst for innovation and economic growth. The facility will house OSU’s research accelerator, the Gaulke Center for Marine Innovation and Technology, and the university’s research office, all of which will help bridge the gap between academia and industry.

Additionally, the strategic location of the complex aims to invigorate the northern edge of OSU’s campus. The design incorporates multiple entry points to enhance accessibility, connecting students and faculty to existing research buildings and social spaces, including nearby restaurants and pubs.

“It’s been more than two years since we made the decision to go with an all-mass-timber structure,” says Ramirez. “The estimated calculation at that time was a 2% increase in cost, but that was balanced by a reduction in schedule.”

The building’s estimated construction cost is $171 million; construction began with excavation in March 2024, and foundation and concrete slab work were completed in November. Mass timber erection commenced in 2024. The project is anticipated to be substantially complete in late fall 2026, with commissioning for the specialty lab spaces and supercomputer to begin at the first of the year 2027.

The Jen-Hsun and Lori Mills Huang Collaborative Innovation Complex exemplifies a forward-thinking approach to academic research infrastructure. By integrating sustainable practices, fostering interdisciplinary collaboration, and leveraging advanced technology, OSU created the first mass plywood lab building in the United States. “Our design team pushed us to think differently, and I think that was very good for us,” notes Ramirez.

By Liz Batchelder

| Organization | Project Role |

|---|---|

|

ZGF Architects LLP

|

Architectural Design, Interior Design, and Space Planning

|

|

PLACE Landscape Architecture

|

Landscape Design

|

|

KPFF Consulting Engineers

|

Structural Engineering

|

|

Affiliated Engineers, Inc. (AEI)

|

Mechanical and Plumbing Engineering

|

|

Andersen Construction

|

General Contractor

|