Faced with growing demand to do more with less, animal laboratory managers are looking for opportunities to drive greater efficiencies. One way forward is the use of digitalization to improve energy efficiency as well as asset and space utilization. But tight budgets, the need to improve data collection and analysis, and insufficient numbers of staff trained to operate the new systems are all holding back adoption, according to experts at Siemens Smart Infrastructure.

Many research institutions have tried to cope with these problems in a non-strategic way, through short-term thinking and siloed decision-making, according to Chad House, head of Siemens Life Sciences Americas. Not surprisingly, such a fragmented approach doesn’t tend to work very well—even getting hold of the data necessary to make a plan is not always easy, he says.

Beyond the Silo

In the past, this tendency toward siloed decision-making was reinforced by the technology. When data was gathered on multiple networks and control systems, it wasn’t easy to get a single view of the state of the laboratory. Now, however, it’s possible to bring multiple data streams together on an intelligent building platform designed to manage and mine the underlying information. This kind of smart network can enhance productivity and safety of animal science facilities in a variety of ways, including better lighting controls, visitor tracking, fault-reporting, and asset optimization.

The gains of this kind of digitalization can be dramatic. Simply improving ventilation management can have a huge impact on energy costs. For example, a recent National Institutes of Health study of ventilation in its largest laboratory found that 44% of its energy use was attributable to ventilation and 22% to cooling. Reducing both the number of air changes per hour and the temperature in cages can save money without compromising—and sometimes actually improving—the health of the lab animals.

Digitalization also makes it much easier to collect high-quality, granular data about air quality, says House. Whether air is being brought in through a tube or monitored by an IoT (Internet of Things) sensor, it is now simpler to get a precise understanding of what contaminants and particulates are present. As a result, air systems can be operated with greater energy efficiency without taking any health risks.

In fact, whatever data you need is probably easier than ever to gather and send to an expert. Today, data can be connected to anyone, anywhere.

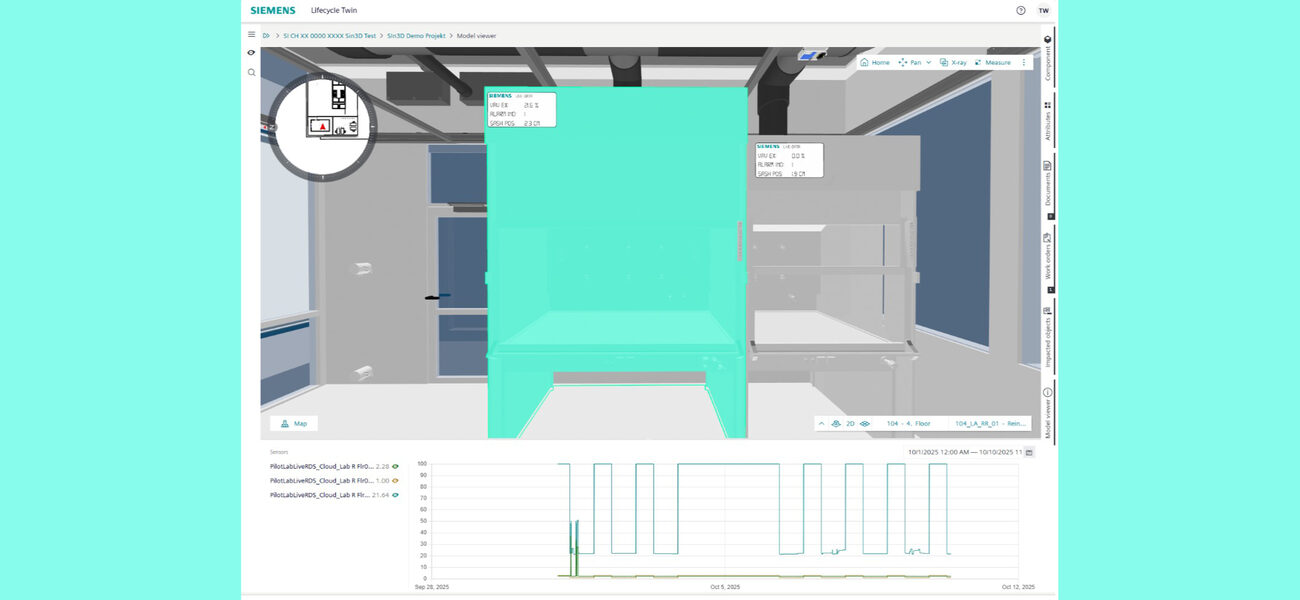

Once collected, the data can also be visualized in increasingly more useful ways. For example, using facilities data to build a digital twin of the facility’s systems can further reduce costs, by making those systems easier to monitor and maintain: Someone brought in to make an adjustment can be shown a picture of the tool, the part, and even the exact place where it needs to be installed.

Modular prefabricated air, heat, and light ceiling systems can further reduce the cost of tweaking the lab environment, according to House. These integrated ceiling units arrive with HVAC components pre-assembled, requiring only a simple installation rather than extensive on-site construction. Workers can quickly connect a few components and lift the complete system into place, eliminating the need for multiple contractors to perform disruptive drilling and installation tasks at the facility.

Handle with Care

Although Siemens experts estimate that most aspects of animal research management can be enhanced through digitalization, they warn of the need for lab managers to proceed with care. In particular, they advise:

- Begin with the problem you are trying to solve, not the technology. Work backward from the resolution you hope to achieve.

- Engage your technology partners early. Include all the stakeholders to make sure that the technology is rolled out in ways that will be useful to everyone. Start by thinking about your risks.

- Think through how your systems interact. Think of your systems as an ecosystem and try to determine the nature of the relationship. Once the relationship is clearer, you can think through what information you will need, says House.

- Design new facilities with support for data collection and model creation in mind from the beginning.

Not everything depends on clear-sightedness, however. House warns that bureaucratic constraints can add another layer of challenges for managers who want to take advantage of the opportunities being offered by integrated technologies.

Academic institutions face particular difficulties organizing these technological implementations due to grant requirements that demand detailed predetermined plans, says House. Once grants specify certain parameters like air-change rates, researchers cannot freely modify these settings, and grant reviewers are often resistant to innovative approaches such as reduced airflow systems. Complications also can arise from unclear funding sources and budget transparency issues within universities.

However, this doesn’t mean lab managers should just accept excessive air changes. House suggests that those developing animal welfare protocols could advocate for lower air change rates by highlighting how these conditions improve animal comfort, thereby gradually advancing acceptance of more efficient approaches.

The debate over digitalizing laboratories is over, in House’s view—the technology is now mature. The only real remaining questions are which systems to install first, and when.

“It’s all possible,” says House. “It’s like any other big computer project: You have to have a plan. You have to organize your data, then you want to try to plan, plan, plan, so you get it right the first time.”

By Bennett Voyles