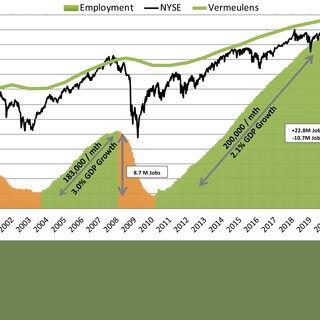

To keep apprised of the dynamics in the current construction environment, Vermeulens, a professional services firm focused on construction cost estimation and pre-construction cost control, has scheduled twice-weekly virtual roundtable discussions with industry leaders in Central and East Coast regions to identify ongoing trends, influencing factors, construction administration issues, and the market outlook in the construction industry. Economic indicators are in flux, and while employment in construction seemed to have avoided the drop seen in other sectors through mid-March, a survey conducted by the Associated General Contractors of America (AGC) shows that conditions are worsening, with 55 percent of the 1,600 repondents nationwide reporting they had been directed to hault work on at least one project, and 27 percent have furloughed or terminated construction workers. The next federal jobs report, which will be issued at the end of April, will provide a truer picture, says James Vermeulen, managing principal of Vermeulens.