Science and engineering are constantly moving knowledge forward, and that means updates to the way we teach and do research. But buildings tend to remain artifacts of the time in which they were built. The future is flexible, and agile design with an inclusive approach can help turn old buildings into places where the next wave of scientists and engineers can flourish.

“Researchers, by design, are problem solvers and they’re going to figure out how to make it work,” explains Joe Walker, owner and principal of Walker Architects. “What happens is, you get a series of decisions made on an existing condition, you start to react to that existing condition, and then you react again, and you react again, and you react again. That leads to a hot mess of spaces and resources that aren’t moving the needle forward, are unattractive for new faculty, and unsafe for students coming in.”

Agile Design

The accretion of building hacks created by innovative people solving immediate issues will eventually lead to a space that’s not usable. “Being able to quickly pivot a lab for a new researcher, or a change in the research type that you’re doing, is of critical importance,” says Walker.

So how to prevent it? By employing “agile design.” Part of it is creating flexible spaces. Perhaps a given lab isn’t going to be used for teaching—at least not now—but collaboration is an important factor in a lot of scientific and research work. If you make the lab a little larger now, it can accommodate students when things change later on, or bring together teams in a space where they can safely observe and contribute to ongoing research.

“For the typical lab module, you often hear 10 feet, 6 inches or 10 feet, 8 inches, and that leaves just less than 5 feet between the two benchtops,” says Walker. “Especially when I put a hood in, and it starts to crunch it up a little bit, I have two people who are maybe sitting back-to-back, and it gets a little tighter. I like to start with a lab module of 11 feet, and in a teaching lab, I actually like to bump it up to 12 feet, so you’re giving folks room to gather.” An 11-by-30-foot standard module can be a double lab, a prep and tissue culture space, a lab manager’s office with equipment storage, a manager’s office with a tissue culture space, or three offices for desk work. With flexible furnishings, research, teaching, and support spaces can expand and contract as needed, as the institution’s priorities change.

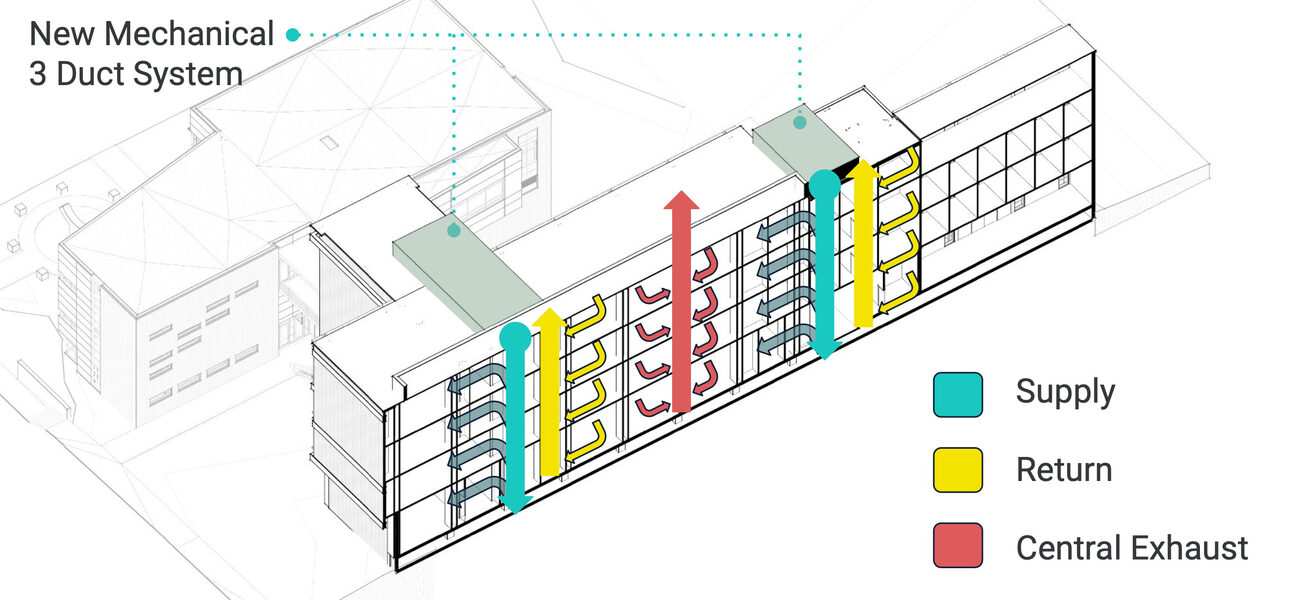

There are some parts of a science building that can’t flex, of course. Air exchanges are an important factor in many research spaces. “There’s always a change in use and there’s always some saying, ‘I need more,’” says Walker. He recommends future-proofing by installing HVAC systems that can direct air to where it’s needed, and can be managed without expensive reconstruction. Walker will often include a three-duct pressurized system from the start, even for spaces that don’t call for that at the moment. “Use a series of valves that can either vent the air from a room or recirculate it, and you can do it with the building automation system,” he says.

For an AI and robotics lab in a data science building at the University of Florida, “A very simple intervention of a grid in the ceiling plane allowed all the little Internet of Things devices to connect, and to give data back to the researchers, and allow them to change it without having to make it up,” he says. “We’ve given them a place and a structure to place items to make their research work.”

People First

Another principle Walker keeps in mind for building renovations is the need to connect and consult with the people involved—not just the faculty and the maintenance crew, but the neighbors, the administrators, the community, the sub-consultants, and the contractors who have to do the work. “When you change the question from, ‘How do I get the best science lab for my user group?’ to ‘How is everybody affected that is going to be touching this building?’ you tend to get different results,” he says.

Full Campus

For a medical device maker, Exactech, Walker renovated a campus in an industrial park, a sprawling complex that had grown organically as the company expanded and more buildings became available. The cumbersome layout was a particular issue for the sales team, who had to use golf carts to conduct client tours. The segmentation of work teams also led to a lack of communication. “There was a big culture divide between the folks making and the folks thinking,” says Walker.

“There were three problems that we had to solve: One was sharing the story. Two was building community. And third, and probably the most important one, was getting the actual science space and manufacturing space right,” says Walker. “What we ended up doing was essentially a small addition, and rethinking how the building went together to make that happen.”

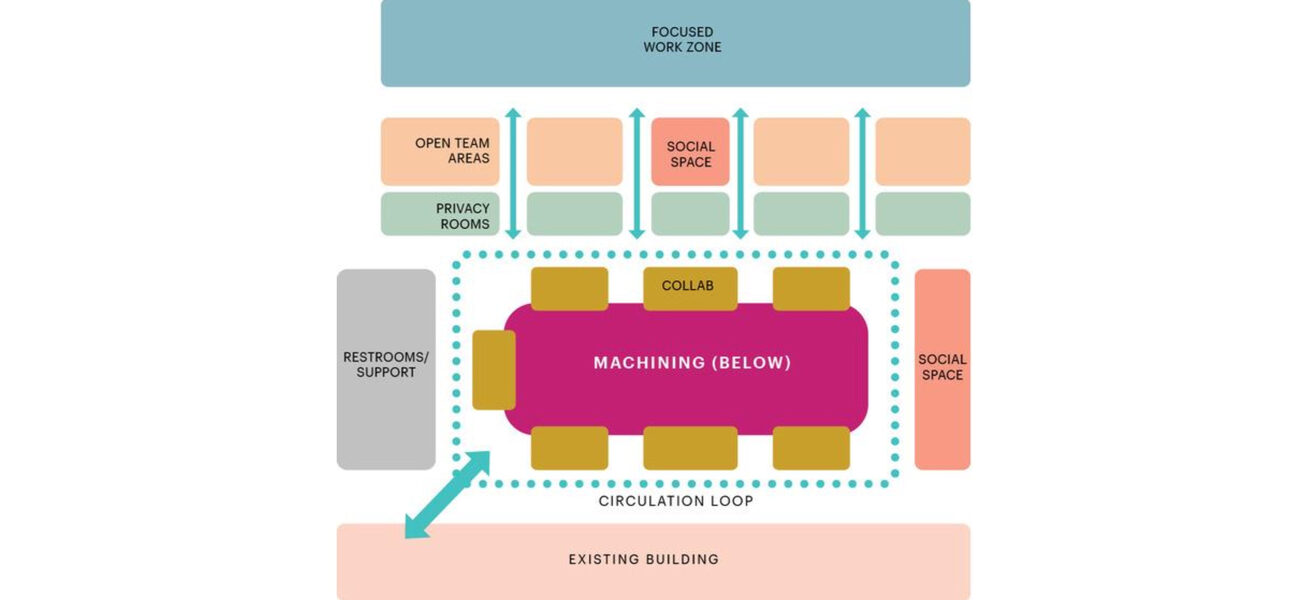

Walker’s team was able to retrofit the main building, with the addition, as a 12-by-12 grid space to make room for the larger pieces of manufacturing equipment, while also building out comfortable and intuitive paths for visitors to see what the company was doing, along with spaces for cross-functional teams to meet and collaborate. The collaborative spaces formed a ring around the manufacturing floor, so groups could have lunches or conversations, all with visibility into the work in progress. Executives and salespeople were able to show off the company’s work safely and in a way that told the story quickly and coherently. “It changed the culture completely,” says Walker.

Whole Building

For the University of Florida’s Chemical Engineering department, Walker undertook to renovate a building from the 1960s. “There were nine air handling units distributed through the building, and the ductwork was spaghetti,” he says. To modernize it, he needed to remove most of what was inside and start over, preserving the bones of the building, which were sturdy and well-built. His engineering team gave the building a new three-duct pressurized system throughout. Old mechanical spaces in the building became research areas, with mechanical sheds moved to the roof.

The new system is programmable and flexible. “One of the fundamental design drivers we are doing on this building is to let the building breathe, and be able to control how the building breathes,” says Walker. Some parts of the building required one-pass air from the outset. Others may be alright with office air for now, but may need higher exchange rates later.

The five-story space became a series of “neighborhoods” for research, teaching, administration, and labs. Walker also wanted to create an attractive and usable front entry area for the old building, which previously brought visitors into a perplexing stairway. The ground level now features a makerspace and specialized labs, plus a series of breakout spaces for teaching and collaboration. “Many buildings that we have walked into are kind of scary and intimidating—that was my front-door experience,” says Walker. His solution: “Putting science on display and carrying the conversation outside of the lab, with a place to sit right there. I don’t have to go hunt for it.”

One Floor

This is a common challenge for institutions—maybe there’s no money for an addition or a whole-building renovation, but there’s a new research team that needs to convert old space into something that will attract top thinkers and facilitate great work. The fundamental driver of great science is collaboration, says Walker, and a converted floor (or even part of a floor) can incorporate conversation spaces and create a welcoming and productive atmosphere.

At in the University of Florida’s Basic Science building, small conference areas are located next to open-bench workstations so researchers can discuss their work. A previously dingy break room now has a light-filled coffee-bar ambience, and a next-door meeting room has a garage-type door that allows it to expand into the break room for larger gatherings. Information-sharing technology in a shared workroom allows collaboration with colleagues at a distance.

By Patricia Washburn