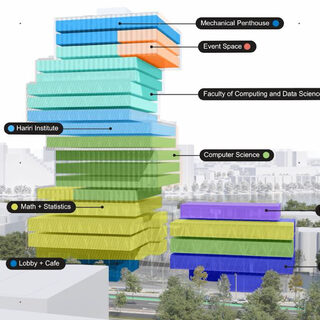

Boston University Builds One of the City’s Largest Sustainable and Operationally Fossil-Fuel-Free Buildings

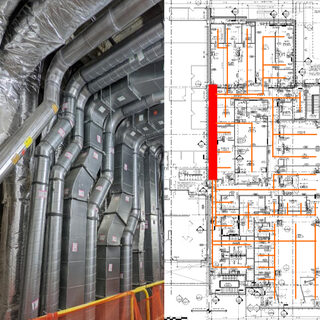

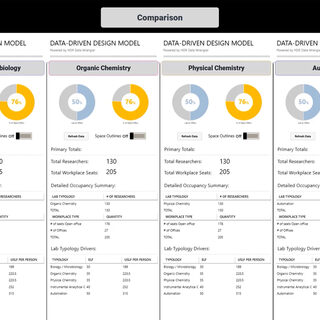

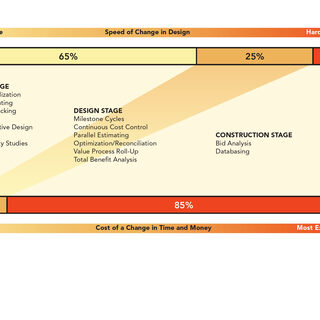

The 350,000-sf Duan Family Center for Computing & Data Sciences at Boston University (BU) brings 3,000 students, faculty, and staff together daily inside a LEED platinum-certified 19-story structure that sits at the heart of the university’s main campus. By replacing most of the building’s Portland cement with other supplementary cementitious materials, installing triple-glazed windows and fins to reduce the solar load, and heating and cooling the building with geothermal boreholes paired with active chilled beams, the project team created one of the largest sustainable and operationally fossil-fuel-free buildings in Boston.